Why Choose Rogers RO4730G3 for High-Frequency Applications?

Rogers RO4730G3 offers compelling advantages that set it apart from traditional PCB materials:

Lightweight Design: 30% lighter than conventional PTFE materials, reducing overall system weight without compromising performance.

Manufacturing Simplicity: Compatible with standard PCB fabrication processes, eliminating the special treatments required for PTFE-based laminates.

Superior Electrical Performance: Consistent dielectric constant of 3.0 with exceptional passive intermodulation performance better than -160 dBc.

Thermal Reliability: High glass transition temperature exceeding 280°C ensures reliable performance in demanding environmental conditions.

Cost Effectiveness: Optimal balance of performance and manufacturing costs for high-volume 5G infrastructure applications.

Understanding Rogers RO4730G3 Material Composition

Core Material Properties

Rogers RO4730G3 is a UL 94 V-0 flame-retardant thermoset laminate. It is constructed from ceramic hydrocarbon materials and combined with low-loss LoPro copper foil. This unique composition delivers the reliability and performance characteristics that antenna designers require for demanding high-frequency applications.

The material maintains a consistent dielectric constant of 3.0, which antenna engineers particularly favor for its balance between performance and design flexibility. The z-direction dielectric constant deviation remains within ±0.05 at 10 GHz, ensuring predictable electrical behavior across the operating frequency range.

Lightweight and Thermal Performance Benefits

Rogers RO4730G3 addresses two critical design challenges simultaneously. The 30% weight reduction compared to traditional PTFE materials makes it excellent for weight-sensitive applications such as aerospace and portable communication devices. Additionally, the material exhibits superior thermal characteristics with a glass transition temperature exceeding 280°C, enabling excellent performance in high-temperature applications and automated assembly processes.

The low Z-axis coefficient of thermal expansion (CTE) of only 30.3 ppm/°C across the temperature range from -55°C to +288°C ensures excellent reliability of electroplated through-hole structures in multilayer circuit assemblies.

Key Technical Specifications of Rogers RO4730G3

Electrical Properties

| Property | Value | Test Frequency/Conditions |

|---|---|---|

| Dielectric Constant (Dk) | 3.0 ± 0.05 | 10 GHz |

| Design Dk | 2.98 | 1.7-5 GHz |

| Dissipation Factor (tanδ) | 0.0028 | 10 GHz, 23°C |

| Loss Tangent | 0.0022 | 2.5 GHz (LoPro EDC foil) |

Thermal and Mechanical Performance

| Property | Value | Test Conditions |

|---|---|---|

| Glass Transition Temperature (Tg) | >280°C | DSC |

| CTE X-axis | 15.9 ppm/°C | -55°C to +288°C |

| CTE Y-axis | 14.4 ppm/°C | -55°C to +288°C |

| CTE Z-axis | 30.3 ppm/°C | -55°C to +288°C |

| Flexural Strength | 181 MPa (MD), 139 MPa (CMD) | IPC-TM-650 |

| Density | 1.58 g/cm³ | ASTM D792 |

| Copper Peel Strength | 4.1 pli | 1oz LoPro EDC |

| Thermal Conductivity | 0.45 W/mK | 50°C |

Exceptional Passive Intermodulation Performance

Understanding PIM in Antenna Systems

Rogers RO4730G3 delivers outstanding passive intermodulation (PIM) performance, typically achieving values better than -160 dBc when measured at 43 dBm input power at 1900 MHz. This exceptional PIM performance makes it particularly valuable for intermodulation-sensitive high-frequency antennas where signal purity is critical for system performance.

The excellent PIM characteristics result from the material’s homogeneous ceramic hydrocarbon composition and the use of high-quality LoPro copper foil. This combination minimizes the generation of unwanted intermodulation products that can degrade system performance in sensitive RF applications.

PCB Fabrication Compatibility

Standard Manufacturing Process Benefits

Rogers RO4730G3 requires no special preparation for plated through-hole formation, unlike traditional PTFE-based materials. The material is fully compatible with conventional epoxy and high-temperature lead-free solder processing. This compatibility eliminates the need for special treatments typically required on traditional PTFE-based laminates, reducing manufacturing complexity and costs.

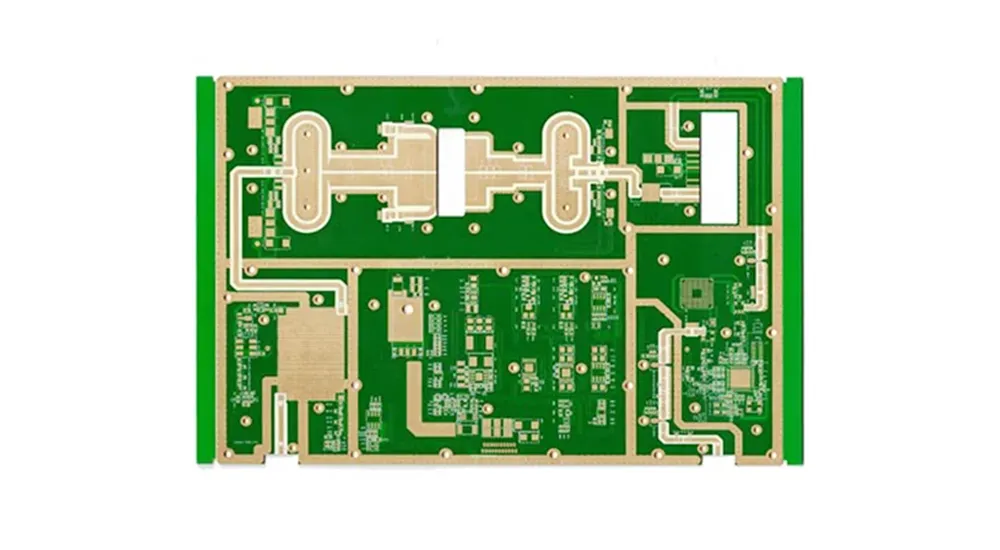

Multilayer Construction and Assembly

Multilayer constructions can be achieved using RO4450F bondply at 175°C, enabling complex antenna designs and integrated circuit solutions. The material’s processing characteristics closely match those of standard FR-4, making it accessible to manufacturers familiar with conventional PCB fabrication techniques.

The high glass transition temperature and thermal stability of Rogers RO4730G3 ensure full compatibility with lead-free soldering processes, meeting modern environmental and regulatory requirements while maintaining excellent electrical performance throughout the assembly process.

Primary Applications and Real-World Use Cases

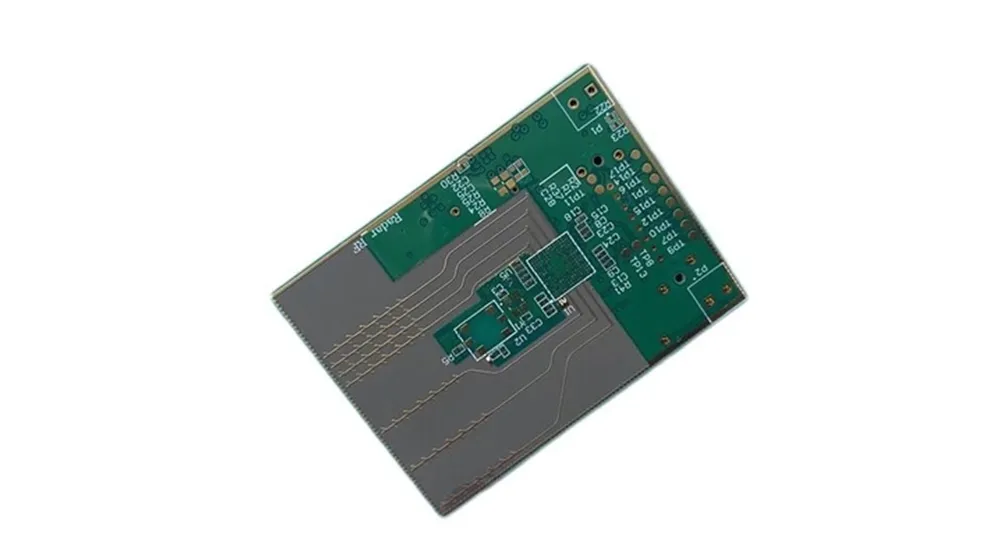

5G Infrastructure and Base Stations

Rogers RO4730G3 has become the material of choice for major telecommunications equipment manufacturers developing 5G base stations and small cell systems. Leading companies like Ericsson and Nokia have successfully implemented RO4730G3 in their active antenna arrays, where its combination of low dielectric constant, minimal loss, and thermal stability enables precise beamforming and signal integrity.

The material’s consistent dielectric properties support the tight impedance control required for maintaining signal integrity in millimeter-wave 5G designs operating at frequencies up to 28 GHz and beyond.

IoT Device Applications

The cost-effective nature of Rogers RO4730G3, combined with its reliable performance characteristics, has made it the preferred choice for high-volume IoT applications. Smart city infrastructure, industrial IoT sensors, and automotive communication modules utilize RO4730G3 to achieve reliable wireless connectivity while meeting stringent cost targets.

Antenna System Success Stories

Automotive radar systems operating at 77-81 GHz have successfully leveraged RO4730G3’s stable dielectric properties for collision avoidance and autonomous driving applications. The material’s excellent dimensional stability ensures consistent antenna performance across temperature variations typical in automotive environments.

Design Considerations and Engineering Best Practices

Impedance Control Optimization

Designers should leverage RO4730G3’s consistent dielectric properties to achieve precise impedance control, which is critical for maintaining signal integrity in high-frequency designs. The material’s tight dielectric constant tolerance enables predictable transmission line characteristics, simplifying the design process for complex RF circuits.

Thermal Management Strategies

While RO4730G3 offers excellent thermal properties, implementing proper thermal management techniques remains important for high-power applications. Standard practices such as thermal vias, heat sinks, and ground plane optimization should be considered based on power dissipation requirements.

Stack-up Design Guidelines

For multilayer applications, proper stack-up design minimizes losses and optimizes overall performance. Working with experienced PCB manufacturers to optimize the manufacturing process for RO4730G3 ensures the best results and helps avoid potential manufacturing issues.

Comparison with Alternative PCB Materials

Advantages Over PTFE Materials for High-Frequency PCBs

Rogers RO4730G3 offers several distinct advantages over traditional PTFE-based materials commonly used in high-frequency applications. The 30% weight reduction, combined with easier processing requirements and better mechanical properties, makes it a superior choice for many antenna applications. The elimination of special hole preparation processes reduces manufacturing complexity and costs significantly.

Cost-Performance Analysis

RO4730G3 provides a practical and cost-effective material solution for current 4G, IoT wireless devices, and active antenna arrays in future 5G wireless devices. The material delivers the optimal combination of price, performance, and durability for demanding applications, making it suitable for both prototype development and high-volume production.

Quality Assurance and Reliability Testing

Electrical Testing Standards

Rogers RO4730G3 undergoes comprehensive electrical testing to ensure consistent performance across production lots. Key parameters including dielectric constant, loss tangent, and dimensional stability are verified according to industry standards such as IPC-4101 and IPC-TM-650, ensuring reliable performance in critical applications.

Environmental Reliability Performance

The material demonstrates excellent performance across wide temperature ranges and humidity conditions. With dimensional stability of less than 0.4 mm/m after etching and exposure to +150°C, Rogers RO4730G3 maintains its physical integrity under demanding environmental conditions typical in telecommunications infrastructure.

Partner with Haoyue Electronics for Expert Rogers RO4730G3 PCB Manufacturing

At Haoyue Electronics, we specialize in precision manufacturing of Rogers RO4730G3 PCBs for 5G infrastructure, IoT applications, and advanced antenna systems. Our experienced engineering team understands the critical importance of material selection and process optimization for high-frequency PCB applications.

With our advanced manufacturing capabilities and comprehensive quality control processes, we ensure that every Rogers RO4730G3 PCB meets the most demanding specifications. Our technical expertise extends beyond manufacturing to include design optimization, stack-up recommendations, and material selection guidance for your specific application requirements.

Ready to optimize your 5G, IoT, or antenna system designs with precision-manufactured, high-performance PCBs? Contact Haoyue Electronics today to discuss your Rogers RO4730G3 requirements and discover how our specialized manufacturing capabilities can accelerate your next-generation wireless communication projects.

Frequently Asked Questions

1. What is the best PCB material for 5G antennas and how does Rogers RO4730G3 compare?

Rogers RO4730G3 is specifically designed for 5G antenna applications, offering an optimal dielectric constant of 3.0, exceptional PIM performance better than -160 dBc, and full compatibility with standard PCB manufacturing processes. Unlike traditional PTFE materials, RO4730G3 eliminates special processing requirements while delivering equivalent electrical performance, making it ideal for high-volume 5G infrastructure deployments.

2. How does Rogers RO4730G3 compare to PTFE for high-frequency applications?

Rogers RO4730G3 provides several key advantages over PTFE materials including 30% lighter weight, no special hole preparation requirements, better mechanical properties, and equivalent electrical performance. The ceramic hydrocarbon composition offers improved dimensional stability and thermal characteristics while maintaining the low dielectric constant that antenna designers require for optimal performance.

3. What are the thermal considerations when designing with Rogers RO4730G3 for automotive applications?

Rogers RO4730G3 features excellent thermal characteristics with a glass transition temperature exceeding 280°C and low Z-axis CTE of 30.3 ppm/°C across automotive temperature ranges. These properties ensure reliable performance in automotive radar and communication systems. The material’s thermal stability eliminates concerns about dimensional changes during temperature cycling, critical for maintaining antenna performance in automotive environments.

4. Is Rogers RO4730G3 suitable for cost-sensitive IoT applications?

Yes, Rogers RO4730G3 provides an optimal balance of cost and performance for IoT applications. The material’s compatibility with standard PCB manufacturing processes reduces fabrication costs compared to specialized PTFE materials, while its reliable electrical performance ensures consistent wireless connectivity. This combination makes it ideal for high-volume IoT deployments where both performance and cost considerations are important factors.