The evolution of high-frequency electronics has driven unprecedented demands for PCB materials that can deliver exceptional performance while maintaining manufacturing feasibility. Rogers RO4350B has emerged as a cornerstone material in this landscape, bridging the gap between standard FR-4 limitations and expensive PTFE-based solutions. This comprehensive analysis examines the technical specifications, performance characteristics, and practical applications of Rogers RO4350B in modern electronic design.

Technical Foundation and Material Composition

Rogers RO4350B represents a sophisticated engineering achievement in laminate technology, utilizing a ceramic-filled, glass-reinforced hydrocarbon resin matrix. This unique composition delivers the electrical performance characteristics required for demanding RF applications while preserving the processability advantages associated with conventional PCB materials.

The material’s architecture incorporates carefully selected ceramic fillers that provide dimensional stability and thermal management capabilities, while the hydrocarbon resin system ensures reliable dielectric performance across extended frequency ranges. The glass reinforcement structure contributes to mechanical integrity without compromising electrical properties, making RO4350B suitable for both single-layer and complex multilayer designs.

Critical Performance Specifications

Dielectric Properties and Signal Integrity

The dielectric performance of Rogers RO4350B establishes its position as a premium choice for high-frequency applications. The material maintains exceptional consistency in its electrical characteristics across varying environmental conditions and frequency ranges.

| Property | Specification | Test Condition |

|---|---|---|

| Dielectric Constant (Dk) | 3.48 ± 0.05 | 10 GHz / 23°C |

| Design Dk | 3.66 | Circuit design reference |

| Loss Tangent (Df) | 0.0037 | 10 GHz / 23°C |

| Loss Tangent (Df) | 0.0031 | 2.5 GHz / 23°C |

| Frequency Range | 500 MHz – 40+ GHz | Operational bandwidth |

The stable dielectric constant across the operational frequency spectrum ensures predictable signal propagation characteristics, enabling accurate impedance control and minimizing signal distortion in high-speed digital and RF circuits.

Thermal Management and Environmental Stability

Thermal performance represents a critical consideration in high-power RF applications, where effective heat dissipation directly impacts system reliability and performance longevity. Rogers RO4350B demonstrates exceptional thermal characteristics with a glass transition temperature exceeding 280°C and thermal decomposition temperature of 390°C, providing substantial margin for high-temperature processing and operational environments. The material exhibits thermal conductivity of 0.69 W/m/K at 80°C, enabling effective heat dissipation in power-sensitive applications.

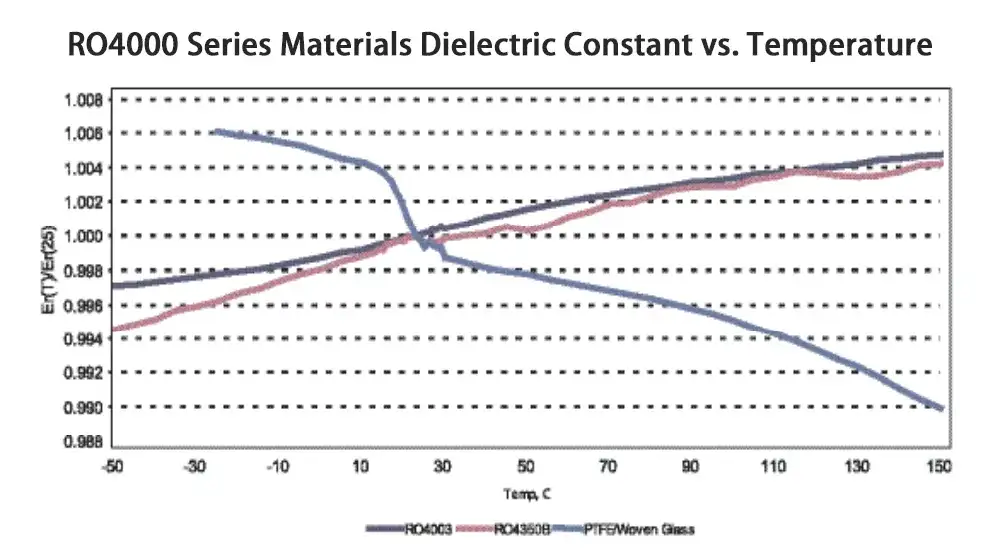

The thermal coefficient of dielectric constant measures +50 ppm/°C across the temperature range from -50°C to 150°C, ensuring dielectric stability across temperature variations. This controlled thermal response enables predictable circuit performance in applications subject to significant temperature fluctuations, from automotive under-hood environments to aerospace applications.

Mechanical Integrity and Dimensional Control

The mechanical properties of RO4350B enable robust performance in demanding applications where physical stress, thermal cycling, and environmental exposure present significant challenges.

| Mechanical Property | X-Axis | Y-Axis | Units |

|---|---|---|---|

| Tensile Modulus | 16,767 | 14,153 | MPa |

| Tensile Strength | 203 | 130 | MPa |

| Coefficient of Thermal Expansion | 10 | 12 | ppm/°C |

| Z-Axis CTE | 32 | – | ppm/°C |

| Flexural Strength | 255 | – | MPa |

The controlled coefficient of thermal expansion values ensure dimensional stability during thermal cycling, reducing stress on plated through-holes and preventing copper trace fractures in multilayer constructions.

Electrical Insulation Performance

Superior electrical insulation characteristics ensure reliable operation in high-voltage and high-frequency environments where signal isolation and system protection are paramount. Rogers RO4350B demonstrates volume resistivity of 1.2 × 10^10 MΩ•cm and surface resistivity of 5.7 × 10^9 MΩ, providing excellent isolation between circuit elements. The material exhibits electrical strength of 31.2 kV/mm (780 V/mil), enabling reliable performance in applications with elevated voltage requirements while maintaining signal integrity across adjacent traces and layers.

Comparative Material Analysis

Rogers RO4350B vs. Standard FR-4

The performance differential between RO4350B and conventional FR-4 becomes pronounced in high-frequency applications where signal integrity and thermal management are critical. RO4350B provides superior dielectric stability across extended frequency ranges, significantly lower loss tangent for reduced signal attenuation, and enhanced thermal performance for high-power applications. The material also demonstrates improved dimensional stability for precision circuit requirements, making it particularly valuable in applications where tight tolerance control is essential.

From a cost-performance perspective, while RO4350B commands a premium over standard FR-4, the performance benefits justify the investment in applications where signal integrity and reliability are non-negotiable requirements. The enhanced electrical and thermal characteristics enable system designs that would be impossible with conventional materials, particularly in frequency ranges above 1 GHz where FR-4 limitations become prohibitive.

Rogers RO4350B vs. PTFE-Based Laminates

PTFE-based materials offer exceptional high-frequency performance but present manufacturing challenges and cost considerations that make RO4350B an attractive alternative for many applications. In comparative analysis, RO4350B provides 80-90% of PTFE performance at 50-60% of the cost, while enabling standard processing techniques that reduce manufacturing complexity. The material offers comparable thermal performance with improved mechanical properties and superior dimensional stability in multilayer applications, making it particularly suitable for complex circuit designs requiring multiple layer configurations.

The manufacturing advantages of RO4350B become particularly evident in high-volume production environments where processing consistency and yield optimization are critical factors. Unlike PTFE-based materials that require specialized handling and processing techniques, RO4350B can be manufactured using conventional PCB fabrication equipment with minimal process modifications.

Design Engineering Considerations

Impedance Control and Signal Routing

Precise impedance control requires careful consideration of material properties, trace geometry, and stackup configuration. Rogers RO4350B’s stable dielectric constant enables accurate impedance prediction and control across varying environmental conditions. Successful implementation requires the use of verified impedance calculators that incorporate RO4350B properties, accounting for dielectric constant tolerance in critical impedance applications.

Design engineers must also consider thermal coefficient effects in temperature-sensitive designs and implement appropriate ground plane configurations for optimal performance. The material’s consistent dielectric properties enable tight impedance control tolerances that are essential for high-speed digital and RF applications where signal integrity directly impacts system performance.

Thermal Management Strategies

Effective thermal management extends beyond material selection to encompass design techniques that optimize heat dissipation and thermal distribution. The incorporation of thermal vias enhances heat transfer in multilayer designs, while copper pour techniques improve overall thermal conductivity throughout the circuit. Component placement strategies must consider thermal hot spot formation, particularly in high-power RF applications where localized heating can degrade performance or cause reliability issues.

Appropriate trace width sizing for current-carrying capacity becomes critical in power distribution networks, where insufficient trace width can create thermal bottlenecks that compromise system performance. The combination of Rogers RO4350B’s inherent thermal properties with thoughtful thermal design practices enables reliable operation in demanding high-power applications.

Multilayer Stackup Optimization

Multilayer designs utilizing RO4350B require careful consideration of layer configuration, material thickness selection, and via design to achieve optimal performance and reliability.

Stackup Considerations:

- Material thickness selection based on impedance requirements

- Symmetric stackup configurations for dimensional stability

- Appropriate prepreg selection for multilayer bonding

- Via aspect ratio limitations and reliability considerations

Manufacturing and Processing Guidelines

Pre-Processing Requirements

Proper material handling and pre-processing ensure optimal manufacturing outcomes and long-term reliability of finished assemblies. Material preparation requires pre-baking at temperatures between 125°C to 150°C for effective moisture removal, followed by storage in controlled environments to prevent contamination. Material acclimation to ambient conditions before processing prevents thermal shock and ensures consistent processing results.

Surface inspection for defects or contamination represents a critical quality control step that prevents downstream manufacturing issues. The implementation of proper material handling protocols directly impacts the reliability and performance of finished circuits, making these preparatory steps essential for achieving optimal results with Rogers RO4350B.

Drilling and Hole Preparation

Precision drilling techniques ensure clean hole formation and reliable plated through-hole performance in demanding applications.

Drilling Parameters:

- New carbide drill bits for optimal hole quality

- Controlled spindle speeds to prevent resin smearing

- Appropriate chip load calculations for material properties

- Entry and backup board selection for clean drilling

Metallization and Surface Finishing

Reliable metallization processes ensure consistent electrical performance and long-term reliability of finished circuits.

Processing Techniques:

- Plasma or chemical desmear for hole preparation

- Electroless copper deposition for reliable conductivity

- Surface treatment options for enhanced adhesion

- Final finish selection based on application requirements

Industry Applications and Use Cases

Telecommunications and 5G Infrastructure

The deployment of 5G networks has created unprecedented demands for PCB materials capable of supporting millimeter-wave frequencies while maintaining cost-effectiveness in large-scale production. Rogers RO4350B addresses these requirements in base station power amplifiers and antenna systems, where signal integrity and thermal management are critical for reliable network performance. The material’s stable dielectric properties enable precise design of millimeter-wave communication modules and beamforming antenna arrays, while its thermal characteristics support the high-power requirements of modern telecommunications infrastructure.

High-speed digital processing modules in 5G systems particularly benefit from RO4350B’s low loss characteristics, which minimize signal degradation in complex multilayer designs. The material’s compatibility with standard manufacturing processes enables cost-effective production of the high-volume circuit boards required for widespread 5G deployment.

Automotive Radar and ADAS Systems

Advanced driver assistance systems and autonomous vehicle technologies rely on precise radar performance, making material selection critical for system reliability and performance.

Automotive Applications:

- 77 GHz automotive radar sensors

- Adaptive cruise control systems

- Blind spot detection modules

- Collision avoidance systems

Aerospace and Defense Electronics

Mission-critical applications in aerospace and defense environments demand materials that deliver exceptional performance under extreme conditions while maintaining long-term reliability.

Specialized Applications:

- Satellite communication systems

- Radar and electronic warfare systems

- Avionics and navigation equipment

- Military communication platforms

Medical and Test Equipment

Precision medical devices and test equipment require materials that provide accurate, repeatable performance while supporting complex circuit designs.

Medical Device Applications:

- MRI and imaging system electronics

- Patient monitoring equipment

- Surgical navigation systems

- Laboratory instrumentation

Quality Assurance and Testing Protocols

Material Characterization and Verification

Comprehensive testing protocols ensure that Rogers RO4350B meets specified performance requirements and maintains consistency across production lots.

Testing Requirements:

- Dielectric constant and loss tangent verification

- Thermal performance characterization

- Mechanical property validation

- Environmental stress testing

Design Validation and Performance Testing

Circuit-level testing validates design performance and ensures that theoretical predictions align with actual circuit behavior.

Validation Approaches:

- Network analyzer measurements for RF performance

- Thermal imaging for thermal management verification

- Mechanical stress testing for reliability assessment

- Environmental testing for long-term stability

Future Developments and Industry Trends

The continuing evolution of high-frequency electronics drives ongoing development in PCB materials technology. Rogers RO4350B represents current best practices while serving as a foundation for future material innovations.

Emerging Trends:

- Integration with advanced packaging technologies

- Enhanced thermal management solutions

- Improved manufacturing processes and cost reduction

- Extended frequency range capabilities

Conclusion

Rogers RO4350B has established itself as a critical enabling technology for modern high-frequency electronic systems. Its unique combination of electrical performance, thermal management capabilities, and manufacturing feasibility makes it an optimal choice for applications ranging from 5G infrastructure to automotive radar systems.

The material’s proven track record in demanding applications, combined with its cost-effective processing characteristics, positions it as a preferred solution for engineers seeking to balance performance requirements with manufacturing practicality. As electronic systems continue to evolve toward higher frequencies and increased complexity, Rogers RO4350B provides the foundation for reliable, high-performance circuit designs.

Partner with Haoyue Electronics for Rogers RO4350B Excellence

At Haoyue Electronics, we specialize in precision PCB manufacturing and assembly services utilizing advanced materials like Rogers RO4350B. Our comprehensive expertise in high-frequency circuit fabrication, combined with state-of-the-art manufacturing capabilities, ensures optimal performance for your critical RF and microwave applications.

Our technical team provides expert guidance throughout the design and manufacturing process, from material selection and stackup optimization to final testing and quality validation. Whether you’re developing 5G infrastructure, automotive radar systems, or aerospace communications equipment, Haoyue Electronics delivers the precision manufacturing and technical support needed to bring your high-performance designs to market successfully.

Contact our engineering team today to discuss your Rogers RO4350B project requirements and discover how our manufacturing expertise can accelerate your product development timeline while ensuring exceptional quality and reliability.