Rogers RO3003 is a high-performance ceramic-filled PTFE laminate designed for RF and microwave applications. Known for its exceptional electrical stability, low loss tangent, and thermal reliability, RO3003 supports frequencies from 3 GHz to 40 GHz, making it ideal for demanding applications in telecommunications, automotive radar, aerospace, and defense.

The material’s unique composition and precisely controlled manufacturing process deliver consistent electrical characteristics that enable engineers to design high-performance circuits for telecommunications, automotive radar systems, aerospace applications, and advanced electronic systems where signal integrity cannot be compromised.

Technical Specifications and Electrical Properties

Core Electrical Characteristics

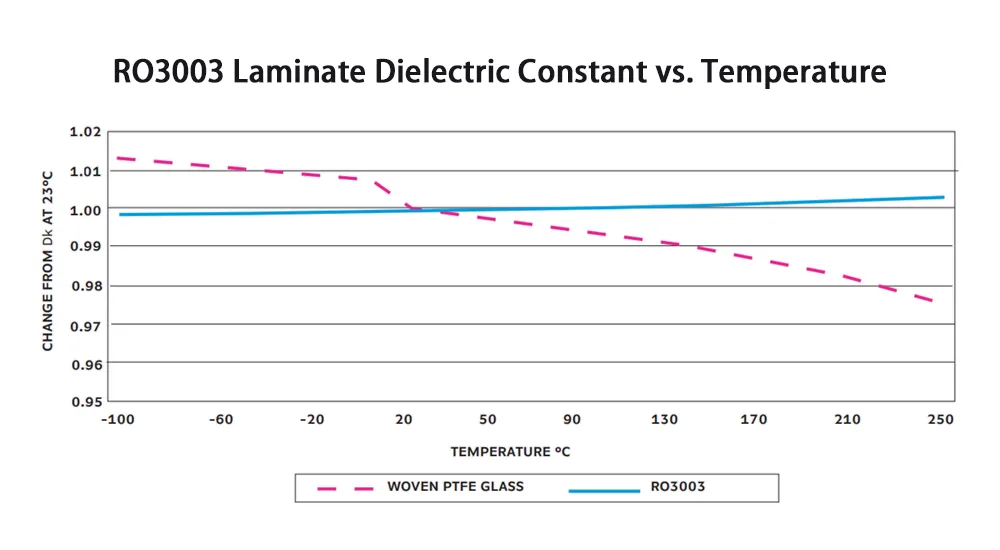

Rogers RO3003 demonstrates superior electrical performance through its carefully engineered material properties. The dielectric constant remains remarkably stable at 3.00 ± 0.04 across the entire frequency spectrum, providing engineers with predictable impedance control essential for high frequency circuit design. This consistency enables precise transmission line calculations and ensures reliable signal propagation characteristics.

The material exhibits an exceptionally low dissipation factor of 0.0013 at 10 GHz, translating directly to minimal signal loss and superior insertion loss performance. This low-loss characteristic becomes increasingly critical as operating frequencies increase, where even small variations in material properties can significantly impact overall system performance.

Thermal and Mechanical Properties

The thermal conductivity of 0.55 W/m/K provides enhanced heat dissipation capabilities compared to traditional FR4 materials, enabling better thermal management in high-power RF applications. The coefficient of thermal expansion in the Z-axis measures approximately 24 ppm/°C, ensuring reliable through-hole plating and via integrity across temperature cycling.

Moisture absorption remains exceptionally low at less than 0.04%, guaranteeing stable electrical performance in humid environments and eliminating the performance drift commonly associated with moisture-sensitive materials.

Material Structure and Composition

Laminate Construction

Rogers RO3003 employs a sophisticated multi-layer construction that optimizes both electrical and mechanical performance. The core substrate consists of ceramic-filled PTFE composite material, which combines the excellent electrical properties of PTFE with the dimensional stability provided by ceramic fillers.

The standard construction includes electrodeposited copper foils bonded to the substrate through specialized adhesive systems designed to maintain electrical performance while providing reliable mechanical adhesion. The copper cladding is available in various weights, typically ranging from 0.5 oz to 2 oz, allowing designers to optimize trace resistance and current-carrying capacity for specific applications.

Available Configurations

The material is manufactured in multiple thickness options to accommodate diverse design requirements. Standard substrate thicknesses include 0.010 inches (0.254 mm), 0.020 inches (0.508 mm), 0.030 inches (0.762 mm), and 0.060 inches (1.524 mm), with custom thicknesses available for specialized applications.

Performance Comparison with Alternative Materials

Rogers RO3003 vs FR4

| Property | Rogers RO3003 | FR4 |

|---|---|---|

| Dielectric Constant | 3.00 ± 0.04 | 4.2-4.8 |

| Loss Tangent | 0.0013 | 0.02-0.025 |

| Thermal Conductivity | 0.55 W/m/K | 0.3 W/m/K |

| Moisture Absorption | <0.04% | 0.1-0.2% |

| Frequency Range | DC-40 GHz | DC-2 GHz |

Rogers RO3003 vs RO4003C

While both materials serve high frequency applications, RO3003 offers lower loss tangent and superior frequency stability, making it preferable for applications above 10 GHz. RO4003C provides a more economical solution for moderate frequency applications with its slightly higher dielectric constant of 3.38.

Applications and Industry Use Cases

Automotive Radar Systems

Rogers RO3003 has become the material of choice for automotive radar applications operating in the 24 GHz and 77-81 GHz frequency bands. The material’s temperature stability and low-loss characteristics ensure reliable performance across the automotive temperature range while maintaining the precision required for advanced driver assistance systems and autonomous vehicle technologies.

Telecommunications Infrastructure

The material excels in base station applications, satellite communication systems, and point-to-point microwave links where consistent electrical performance directly impacts system reliability and data transmission quality. The low moisture absorption characteristic proves particularly valuable in outdoor telecommunications equipment exposed to varying environmental conditions.

Aerospace and Defense Applications

Military and aerospace systems demand materials that maintain performance under extreme environmental conditions. Rogers RO3003 meets these requirements through its stable dielectric properties, reliable thermal performance, and consistent mechanical characteristics across wide temperature ranges.

Design Considerations for Optimal Performance

Impedance Control and Signal Integrity

Achieving precise impedance control requires careful consideration of trace geometry, substrate thickness, and copper weight selection. The stable dielectric constant of Rogers RO3003 simplifies impedance calculations and enables tighter tolerance control compared to materials with frequency-dependent dielectric properties.

Engineers should implement proper ground plane design to ensure low-impedance return paths for high frequency signals. Solid ground planes minimize ground bounce and provide electromagnetic shielding that maintains signal integrity in dense circuit layouts.

Thermal Management Strategies

Effective thermal management becomes critical in high-power RF applications. Design strategies should include appropriate copper pour areas for heat spreading, strategic via placement for thermal conduction, and consideration of component placement to minimize thermal hotspots.

The material’s thermal conductivity allows for efficient heat transfer through the substrate, but designers must still implement proper thermal pathways to external heat sinks or thermal management systems for high-power applications.

Manufacturing Guidelines and Best Practices

Fabrication Considerations

Rogers RO3003 requires specialized manufacturing processes to maintain its superior electrical properties. Drilling operations must use appropriate feed rates and spindle speeds to prevent delamination or rough hole walls that could impact via reliability.

The lamination process demands precise temperature and pressure control to ensure proper adhesion between layers while avoiding degradation of the PTFE substrate. Typical lamination temperatures range from 375°C to 390°C with pressures between 200-400 psi, though specific parameters should be confirmed with the material supplier.

Surface Finishing Options

Compatible surface finishes include Electroless Nickel Immersion Gold (ENIG), Organic Solderability Preservative (OSP), and Hot Air Solder Leveling (HASL). ENIG provides excellent solderability and wire bonding characteristics for high frequency applications, while OSP offers a cost-effective solution for standard assembly processes.

Quality Assurance and Testing

Electrical Characterization

Comprehensive testing protocols ensure consistent material performance. Key test parameters include dielectric constant measurement across frequency, dissipation factor verification, and thermal coefficient characterization. These tests validate that each material lot meets the stringent specifications required for high frequency applications.

Reliability Testing

Environmental stress testing confirms material stability under temperature cycling, humidity exposure, and thermal shock conditions. These tests ensure long-term reliability in demanding applications where material degradation could compromise system performance.

Partner with Haoyue Electronics for Rogers RO3003 PCB Solutions

At Haoyue Electronics, we specialize in manufacturing and assembling high frequency PCBs using Rogers RO3003 and other advanced materials. Our experienced engineering team understands the critical design and manufacturing considerations required to maximize the performance of Rogers RO3003 in your applications.

Our capabilities include precision controlled impedance fabrication, multi-layer high frequency constructions, and comprehensive testing services to ensure your PCBs meet the most demanding specifications. From prototype development to high-volume production, we provide the expertise and quality assurance your projects demand.

Whether you’re developing next-generation radar systems or high frequency telecommunication infrastructure, Haoyue Electronics delivers the precision and expertise your design deserves. Speak with our RF engineering team to get started.

FAQ

1. What is the typical cost difference between Rogers RO3003 and standard FR4 materials?

Rogers RO3003 typically costs 8-12 times more than standard FR4 material due to its specialized PTFE-ceramic composition and precise manufacturing requirements. However, this cost differential must be evaluated against the significant performance advantages in high-frequency applications.

The superior electrical properties, reduced signal loss, and enhanced reliability often justify the higher material cost in applications where performance directly impacts system functionality. Additionally, the material’s consistency and reliability can reduce overall project costs by minimizing design iterations and improving manufacturing yields.

2. How should Rogers RO3003 be stored to maintain its electrical properties?

Rogers RO3003 requires controlled storage conditions to preserve its exceptional electrical characteristics. The material should be stored in a clean, dry environment with relative humidity maintained below 50 percent and temperature between 15°C to 25°C. The laminate should remain in its original packaging until use to prevent contamination and moisture absorption.

Proper storage includes keeping the material away from direct sunlight and chemical vapors that could affect the surface copper or substrate properties. When stored correctly, Rogers RO3003 maintains its specified electrical properties for extended periods, though it is recommended to use material within two years of manufacture date for optimal performance.

3. Can Rogers RO3003 be processed using standard PCB manufacturing equipment?

Rogers RO3003 can be processed using standard PCB manufacturing equipment with specific parameter adjustments and considerations. Drilling operations require carbide drill bits and optimized feed rates to prevent delamination, typically operating at lower speeds than conventional FR4 processing. Routing and milling operations must account for the material’s different mechanical properties to ensure clean edge definition.

The lamination process requires precise temperature control within the 375°C to 390°C range and appropriate pressure application. While most established PCB manufacturers can process Rogers RO3003, it is essential to work with fabricators experienced in high-frequency materials to ensure optimal results and yield rates.

4. What temperature range can Rogers RO3003 reliably operate within for long-term applications?

Rogers RO3003 demonstrates reliable performance across a broad temperature range from -55°C to +200°C for continuous operation. The material maintains its electrical properties with minimal drift across this temperature spectrum, making it suitable for both indoor and outdoor applications in varying climatic conditions.

Short-term exposure to temperatures up to 260°C during soldering processes does not degrade the material properties when proper thermal management techniques are employed. The low coefficient of thermal expansion ensures dimensional stability and via reliability throughout thermal cycling, while the stable dielectric constant prevents impedance variations that could affect circuit performance in temperature-sensitive applications.