What is FR4 PCB Material

FR4 PCB material stands as the most widely adopted PCB substrate, constructed from woven glass fiber cloth impregnated with flame-retardant epoxy resin. The designation “FR4” derives from “Flame Retardant 4,” indicating compliance with UL94 V-0 flammability standards that prevent fire propagation. This glass-reinforced epoxy laminate combines exceptional mechanical strength with reliable electrical insulation properties.

The FR4 material PCB structure consists of multiple layers of glass fabric bound with thermosetting epoxy resin, creating a rigid substrate that maintains dimensional stability across temperature variations. Modern FR4 formulations incorporate brominated flame retardants or halogen-free alternatives to meet increasingly stringent environmental regulations while preserving fire safety characteristics.

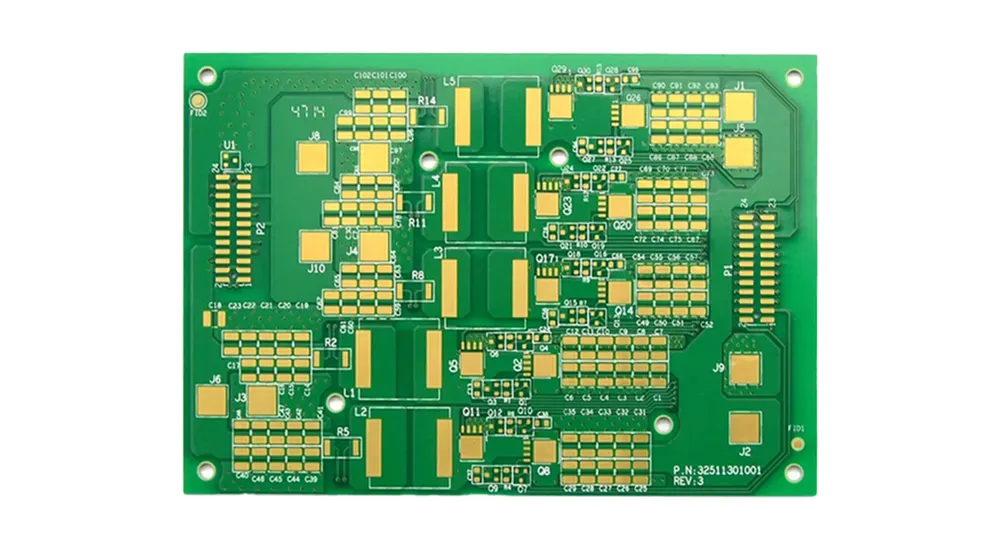

FR4 PCB Board Construction Types

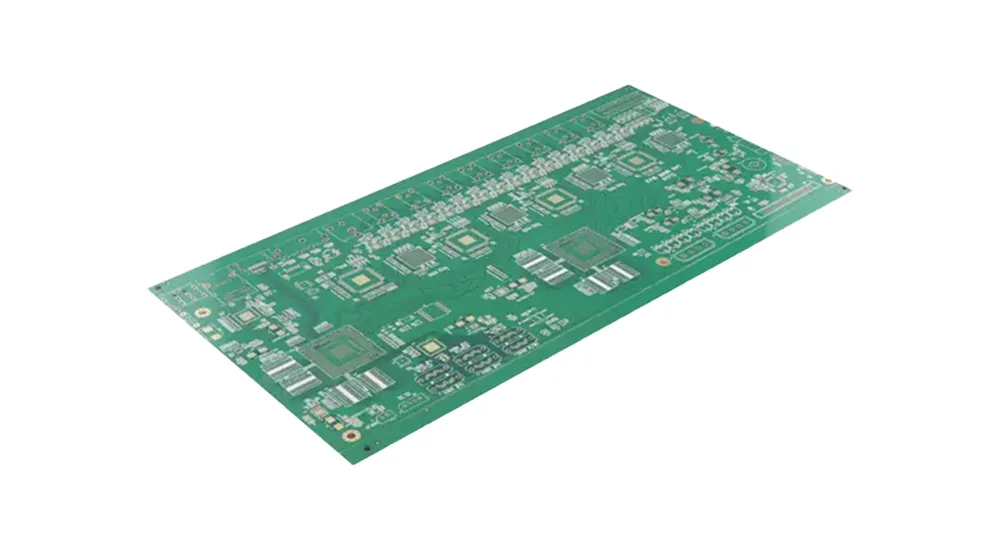

FR4 PCB board configurations range from simple single-layer designs to complex multi-layer FR4 PCB assemblies containing 20 or more layers. Single-sided FR4 boards feature copper traces on one surface, suitable for basic electronic devices. Double-sided configurations provide increased routing density, while multilayer designs enable compact, high-performance electronic systems through internal layer interconnections via plated through-holes and microvias.

The versatility of FR4 material allows customization for specific applications, including high-Tg variants for elevated temperature operations, low-loss formulations for high-frequency circuits, and ultra-thin constructions for portable electronics requiring minimal board thickness.

FR4 PCB Properties and Specifications

Understanding FR4 PCB properties requires detailed examination of electrical, thermal, and mechanical characteristics that determine application suitability. These specifications directly influence circuit performance, reliability, and manufacturing considerations across diverse operating environments.

Electrical Properties and Dielectric Performance

The dielectric constant (Dk) of standard FR4 ranges from 4.2 to 4.8 at 1 GHz, with frequency-dependent variations that affect high-speed signal integrity. Loss tangent (Df) typically measures 0.015 to 0.020 at 1 GHz, contributing to signal attenuation in high-frequency applications. Volume resistivity exceeds 10^6 megohm-cm, providing excellent insulation between circuit layers.

Breakdown voltage capabilities reach 40-50 kV/mm thickness, ensuring reliable operation under high-voltage conditions. Surface resistivity exceeds 10^5 megohms, preventing unwanted current paths between adjacent traces. These electrical specifications make standard FR4 suitable for applications operating below 1 GHz, though specialized low-loss variants extend usability to higher frequencies.

Thermal Performance Characteristics

FR4 PCB thermal properties significantly impact circuit performance and reliability in temperature-varying environments. Glass transition temperature (Tg) for standard FR4 measures 130-140°C, above which mechanical properties degrade substantially. High-Tg FR4 variants offer enhanced thermal performance with Tg values reaching 170-180°C for demanding applications.

Thermal conductivity of FR4 measures approximately 0.3 W/m·K, classifying it as a thermal insulator rather than conductor. This limitation necessitates careful thermal management in high-power applications through copper pour strategies, thermal vias, and heat sinks. Coefficient of thermal expansion (CTE) varies directionally: 14-17 ppm/°C in the X-Y plane and 45-65 ppm/°C through thickness (Z-axis).

Decomposition temperature exceeds 345°C, providing adequate safety margins for standard soldering processes. Operating temperature range typically spans -55°C to +125°C for standard grades, with specialized formulations extending to +150°C or higher.

Mechanical and Physical Properties

FR4 demonstrates exceptional mechanical strength with flexural strength reaching 415 MPa and tensile strength exceeding 310 MPa. These properties enable robust PCB designs capable of withstanding mechanical stress during assembly and operation. Young’s modulus measures approximately 22 GPa, providing dimensional stability under mechanical loading.

Moisture absorption remains below 0.1% after 24-hour immersion, ensuring stable electrical properties in humid environments. This low absorption rate prevents dimensional changes and electrical property degradation common in hygroscopic materials. Specific gravity measures 1.85 g/cm³, contributing to lightweight PCB assemblies.

Detailed FR4 material properties analysis reveals additional characteristics including peel strength, thermal shock resistance, and long-term aging behavior critical for reliability-critical applications.

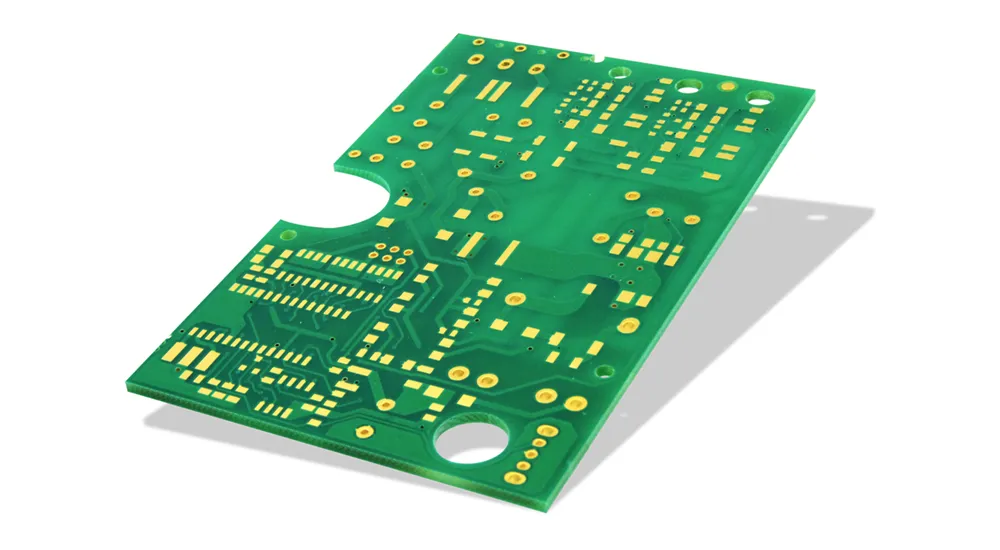

FR4 PCB Manufacturing Process and Design Considerations

FR4 PCB manufacturing encompasses sophisticated processes that transform raw laminate materials into precision electronic substrates. Understanding these manufacturing steps enables designers to optimize layouts for manufacturability while achieving required performance specifications.

Substrate Preparation and Layer Stackup

The FR4 PCB manufacturing process begins with substrate preparation involving precise cutting of FR4 core materials and prepreg layers according to design specifications. Layer stackup design considers impedance control requirements, thermal management needs, and mechanical constraints to achieve optimal electrical performance.

Prepreg selection involves matching resin content, glass style, and flow characteristics to specific design requirements. B-stage prepreg materials provide interlayer bonding during lamination while maintaining controlled dielectric thickness for impedance management. Core material thickness selection balances mechanical strength requirements with electrical performance considerations.

Drilling and Plating Operations

Precision drilling operations create holes for component mounting and interlayer connections using carbide drills or laser drilling systems. Hole quality directly impacts plating reliability and electrical performance, requiring careful control of drill parameters, entry/exit materials, and debris removal processes.

Electroless copper deposition initiates conductive layer formation within drilled holes, followed by electrolytic copper plating to achieve required thickness and conductivity. Through-hole plating quality affects signal integrity and thermal performance, particularly in high-current applications requiring low-resistance connections.

Pattern Formation and Surface Finishing

Photolithographic processes define conductive patterns using photoresist application, exposure, and development sequences. Pattern accuracy and edge definition influence high-frequency performance and manufacturing yield, requiring precise registration and exposure control systems.

Surface finishing operations protect copper surfaces while enabling reliable component attachment. Options include HASL (Hot Air Solder Leveling), ENIG (Electroless Nickel Immersion Gold), OSP (Organic Solderability Preservative), and immersion silver, each offering distinct advantages for specific applications and assembly processes.

FR4 PCB Applications and Performance Comparison

FR4 PCB applications span virtually every electronic industry segment, from consumer electronics to aerospace systems. Understanding performance characteristics relative to alternative materials guides optimal material selection for specific application requirements.

Consumer Electronics and Computing

Consumer electronics represent the largest FR4 PCB application segment, leveraging cost-effectiveness and adequate performance for mainstream products. Smartphones, tablets, laptops, and gaming systems utilize FR4 substrates for main boards, power supplies, and interface circuits operating at moderate frequencies and power levels.

Computing applications including motherboards, graphics cards, and server systems exploit FR4’s mechanical stability and thermal characteristics. Multi-layer FR4 PCB designs enable complex routing in compact form factors while maintaining signal integrity for digital communication protocols.

Industrial and Automotive Electronics

Industrial automation systems require robust PCB substrates capable of withstanding harsh environmental conditions including temperature cycling, vibration, and chemical exposure. FR4’s flame retardant properties and mechanical strength make it suitable for motor control drives, sensor interfaces, and communication modules in factory automation applications.

Automotive electronics increasingly rely on FR4 substrates for engine management systems, infotainment platforms, and advanced driver assistance systems (ADAS). Extended temperature variants accommodate under-hood installations while maintaining reliability over vehicle operational lifetimes.

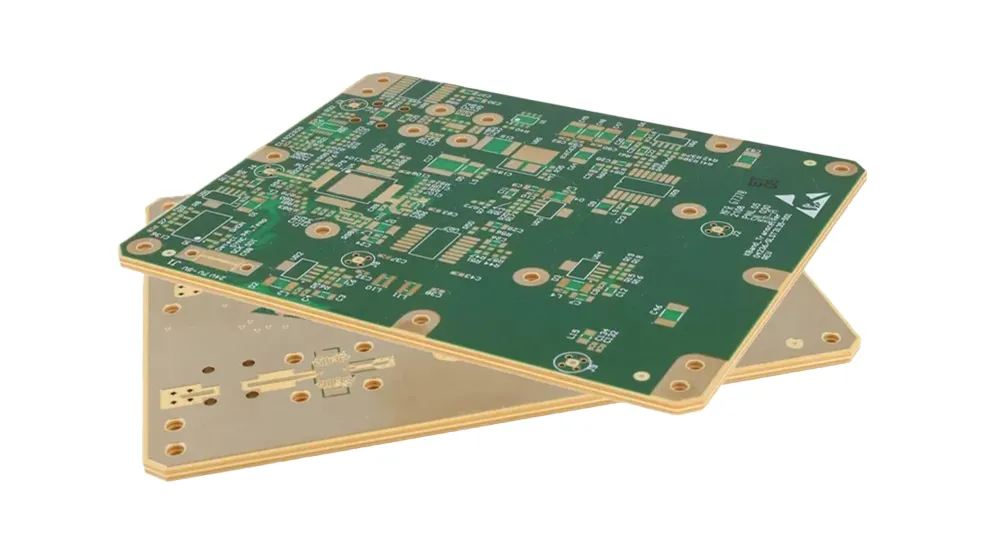

Performance Comparison with Alternative Materials

FR4 PCB vs other PCB materials analysis reveals distinct advantages and limitations relative to specialized substrates. Rogers PCB materials offer superior high-frequency performance with lower loss tangent and stable dielectric constant, but command significantly higher costs limiting adoption to RF/microwave applications.

Polyimide substrates provide enhanced thermal performance and flexibility for aerospace applications, while ceramic substrates offer excellent thermal conductivity for high-power applications. Metal core PCBs excel in thermal management but sacrifice electrical isolation capabilities. FR4 remains optimal for applications requiring balanced electrical, mechanical, and thermal performance at competitive costs.

How to Choose FR4 PCB for Your Project

Selecting appropriate FR4 PCB specifications requires systematic evaluation of electrical, thermal, mechanical, and economic factors specific to each application. This analysis process ensures optimal performance while minimizing costs and development risks.

Electrical Performance Requirements

High-frequency applications demand careful consideration of dielectric constant stability and loss tangent characteristics. Standard FR4 suffices for digital circuits operating below 1 GHz, while specialized low-loss variants extend usability to higher frequencies. Signal integrity analysis should evaluate impedance control requirements, crosstalk limitations, and insertion loss budgets.

Power distribution design influences copper weight selection and thermal management strategies. High-current applications benefit from heavier copper weights (2-4 oz.) combined with thermal vias for heat dissipation. Voltage isolation requirements determine minimum dielectric thickness and clearance specifications according to safety standards.

Thermal Management Considerations

Operating temperature range analysis guides FR4 grade selection between standard and high-Tg variants. Applications experiencing continuous operation above 125°C require high-Tg materials to maintain mechanical properties and prevent delamination. Thermal cycling environments necessitate evaluation of CTE mismatch effects on component reliability.

Power dissipation calculations determine thermal management requirements including copper pour strategies, thermal vias, and heat sink mounting considerations. FR4’s limited thermal conductivity requires careful thermal design to prevent hot spots and ensure component reliability.

Economic and Manufacturing Factors

FR4 PCB cost factors include material specifications, layer count, board thickness, and surface finish selection. Standard FR4 grades offer significant cost advantages over specialized materials while meeting performance requirements for most applications. Volume considerations influence material selection and manufacturing process optimization.

Manufacturing constraints including minimum feature sizes, aspect ratios, and tolerances affect design complexity and yield considerations. Early supplier engagement ensures manufacturing feasibility while optimizing costs through design for manufacturability principles.

Application-Specific Selection Guidelines

Consumer electronics typically utilize standard FR4 with cost optimization prioritized over specialized performance characteristics. Industrial applications may require enhanced thermal performance through high-Tg variants or improved chemical resistance for harsh environments.

Telecommunications equipment benefits from low-loss FR4 variants for improved signal integrity, while automotive applications require temperature cycling resistance and long-term reliability validation. Medical devices may necessitate biocompatible surface treatments and enhanced cleanliness standards.

Why Choose Haoyue Electronics for FR4 PCB Projects

Haoyue Electronics delivers comprehensive FR4 PCB manufacturing and assembly solutions backed by advanced manufacturing capabilities and rigorous quality systems. Our expertise in FR4 PCB applications enables optimized designs that balance performance requirements with cost-effectiveness across diverse industry segments.

Advanced Manufacturing Capabilities

- Precision FR4 PCB Manufacturing: State-of-the-art equipment supporting 4-20 layer constructions with minimum trace/space down to 3/3 mil and via sizes to 0.1mm diameter

- Comprehensive Material Portfolio: Extensive FR4 grade selection including standard, high-Tg, low-loss, and halogen-free variants from leading global suppliers

- Quality Certification Standards: ISO 9001:2015, ISO 14001:2015, and IPC Class 2/3 certifications ensuring consistent quality and reliability

- Complete Assembly Services: Full turnkey PCB assembly capabilities including SMT, through-hole, and mixed-technology assemblies with automated optical inspection

- Engineering Support: Experienced design for manufacturability review and optimization services to enhance yield and reduce costs

- Rapid Prototyping: Express prototype services with 24-48 hour turnaround capabilities for accelerated development cycles

Our commitment to technological advancement and customer satisfaction has established Haoyue Electronics as a trusted partner for FR4 PCB projects ranging from prototype development to high-volume production. Contact our engineering team today to discuss how our FR4 PCB expertise can optimize your next project’s performance, reliability, and cost-effectiveness.