Introduction

High speed PCB via design represents one of the most critical aspects of modern electronic circuit development, directly impacting signal integrity, impedance control, and routing density. As digital systems operate at increasingly higher frequencies and data rates, traditional through-hole vias introduce significant parasitic effects that can degrade performance.

This comprehensive analysis examines blind via, buried via, and microvia technologies in high speed applications, providing essential insights for engineers designing multilayer PCB systems where signal quality cannot be compromised.

Why Via Design is Critical for High Speed PCB Performance

High frequency signals encounter substantial challenges when transitioning between layers through conventional vias. Signal integrity issues manifest through impedance discontinuities, where via structures create characteristic impedance variations that generate reflections and signal degradation. The parasitic inductance and capacitance introduced by traditional through-hole vias become increasingly problematic as rise times decrease and frequencies increase.

In high-speed PCB design, every via represents a potential bottleneck for signal transmission. Via stubs act as unterminated transmission line segments, creating resonances that cause insertion loss and return loss degradation. Additionally, the electromagnetic coupling between adjacent vias contributes to crosstalk, while the disruption of reference planes affects return current paths, potentially increasing electromagnetic interference.

The fundamental limitations of through-hole vias in high speed applications necessitate advanced via technologies that minimize parasitic effects while maintaining manufacturing reliability and cost-effectiveness.

Via Types Analysis in High Speed PCBs

Through-Hole Vias

Through-hole vias penetrate the entire PCB stackup, connecting any layer to any other layer within the board structure. These traditional vias offer mature manufacturing processes and represent the most cost-effective interconnect solution for multilayer designs.

The primary advantages include established fabrication techniques, wide manufacturer support, and lower production costs. However, through-hole vias introduce significant parasitic inductance and capacitance, particularly problematic in high frequency applications. The via stub effect becomes pronounced when signals do not require full board penetration, creating unwanted resonances that degrade signal quality.

Blind Vias

Blind vias establish connections between outer layers and internal layers without penetrating the complete board thickness. This technology significantly reduces signal path length and eliminates unnecessary via stubs that contribute to signal reflection and insertion loss.

The implementation of blind via high speed PCB designs offers substantial advantages for multilayer constructions where signal routing density demands sophisticated interconnect solutions. By terminating vias at specific internal layers, designers achieve improved signal integrity while maintaining compact board geometries. The reduced via stub length minimizes parasitic effects, making blind vias particularly valuable for high frequency differential pair routing and critical timing signals.

Manufacturing complexity increases compared to through-hole vias, requiring precise depth control during drilling operations and specialized plating processes to ensure reliable interconnections.

Buried Vias

Buried vias exist entirely within internal layers, connecting specific layer pairs without affecting surface routing areas. This approach maximizes surface real estate utilization while providing essential interlayer connectivity for complex multilayer designs.

Buried via PCB design offers optimal routing density benefits, particularly valuable in high pin count applications where surface area constraints limit traditional routing approaches. The complete isolation from external layers eliminates any impact on surface mount component placement while providing robust internal signal distribution.

The manufacturing challenges associated with buried vias include increased process complexity, higher production costs, and extended fabrication timelines. Sequential lamination processes become necessary, requiring careful coordination of drilling, plating, and lamination cycles to achieve reliable results.

Microvias

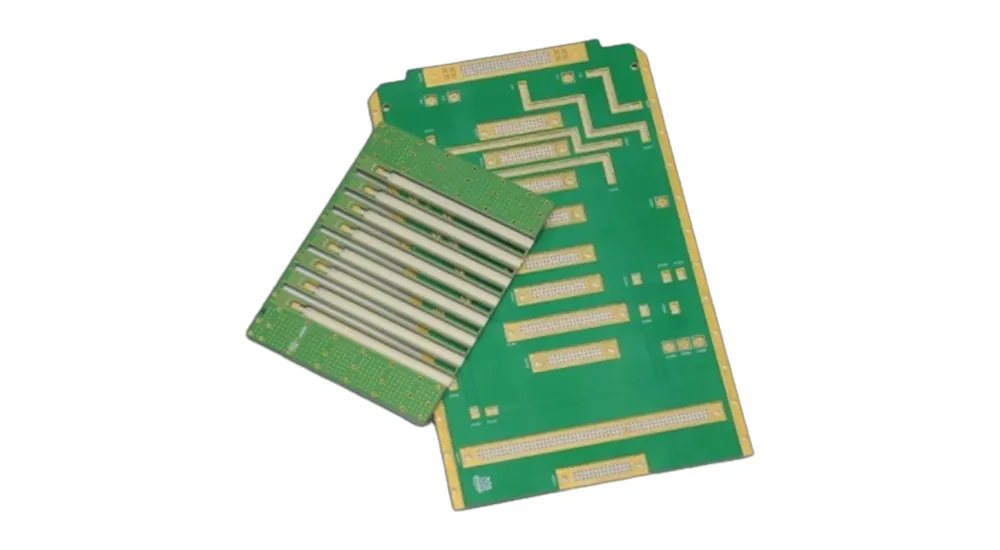

Microvias represent the most advanced via technology, utilizing laser drilling to create small diameter connections typically measuring less than 150 micrometers. These precision-drilled vias enable high density interconnect (HDI) PCB stackup configurations essential for modern high speed applications.

Microvia PCB technology provides minimal parasitic effects due to the reduced via geometry, supporting superior high frequency performance compared to conventional drilling methods. The small via size enables fine pitch routing capabilities essential for modern BGA packages and high density component layouts.

The laser drilling process allows precise control over via dimensions and positioning, supporting stacked and staggered microvia configurations that optimize routing flexibility while maintaining signal integrity requirements.

Advanced Microvia Design Considerations for High Speed Applications

The use of microvias in high speed PCBs requires both electromagnetic expertise and advanced manufacturing control. Key design factors include via configuration, impedance control, parasitic effects, and process tolerances.

1. Stacked vs. Staggered Microvias

- Stacked microvias

- Provide the shortest vertical signal path.

- Reduce routing complexity but concentrate thermal stress.

- Typically limited to 2–3 stacked levels due to stability concerns.

- Staggered microvias

- Offset placement distributes stress and improves reliability.

- Require longer routing, but preferred in harsh environments (automotive, aerospace).

2. Impedance and Parasitic Effects

- Controlled impedance depends on via diameter, plating thickness, and dielectric material.

- Proper coordination between via and trace geometry minimizes signal reflections.

- Parasitic modeling is essential: microvias reduce inductance but may increase capacitive coupling.

- Ground vias should be strategically placed to ensure low-inductance return paths.

3. Manufacturing Tolerances

- Laser-drilled microvias are sensitive to diameter uniformity, plating consistency, and positional accuracy.

- Variations can impact impedance control and signal performance.

- Advanced HDI manufacturers apply statistical process control (SPC) to maintain consistency.

Practical Design Guidelines

Effective high speed PCB via design depends on applying proven principles that balance electrical performance with manufacturing feasibility. The following guidelines highlight key considerations:

1. Minimize Unnecessary Layer Transitions

-

Each via introduces a potential impedance discontinuity.

-

Keep routing as direct as possible to reduce transition count and signal distortion.

2. Stub Removal with Back Drilling

-

Back drilling removes unused via stubs, eliminating unterminated segments that degrade high-frequency signals.

-

Success requires precise depth control to avoid damaging adjacent layers or compromising via strength.

3. Ensure Return Path Continuity

-

Place ground vias adjacent to signal vias to provide low-inductance return paths.

-

This reduces loop area and helps control EMI in high speed designs.

4. Differential Pair Routing Through Vias

-

Maintain matched via structures for each signal in a differential pair.

-

Symmetry in stub length, geometry, and return path ensures consistent timing and impedance.

5. Collaborate with Manufacturers Early

-

Confirm design rules such as laser drilling tolerances, minimum spacing, and aspect ratio limits.

-

Early communication avoids manufacturability issues and improves yield.

6. Manage Crosstalk and EMI

-

Strategic via placement reduces electromagnetic coupling between adjacent vias.

-

Proper use of ground vias enhances shielding and minimizes unwanted interference.

Design and Manufacturing Trade-offs

Selecting the right via technology for high speed PCBs involves balancing multiple factors: electrical performance, cost, reliability, and manufacturing capability. Each option presents benefits and limitations that directly influence overall system design.

1. Cost vs. Performance

- Through-hole vias remain the most economical choice, but they introduce significant parasitic capacitance and inductance, making them less suitable for high frequency designs.

- Blind, buried, and microvias deliver better electrical performance by shortening signal paths and reducing parasitic effects. However, these benefits come with higher fabrication costs and more demanding process control.

- Total cost considerations extend beyond fabrication. Additional design effort, tighter testing requirements, and potential yield loss can all impact project budgets and timelines.

2. Manufacturing Capability

- Advanced via structures require specialized capabilities such as laser drilling, sequential lamination, and precise registration systems.

- Not every PCB manufacturer offers HDI-level technology, which can reduce supplier options and extend lead times.

- Early communication with manufacturers is essential to confirm process limits and ensure that via requirements align with available production capabilities.

3. Reliability Considerations

- Microvia reliability depends on careful design: adequate copper plating thickness, controlled aspect ratios, and compatible dielectric materials are critical.

- In high-reliability applications such as aerospace and automotive, thermal cycling and mechanical shock performance must be evaluated thoroughly.

- Long-term reliability often becomes the deciding factor when justifying the use of more advanced, higher-cost via technologies.

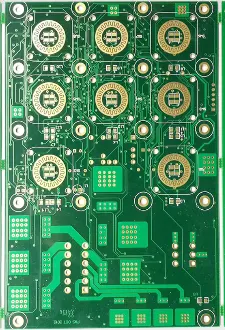

Haoyue Electronics: Advanced Via Manufacturing Capabilities

At Haoyue Electronics, our comprehensive PCB manufacturing and assembly capabilities encompass the full spectrum of advanced via technologies required for modern high speed applications. Our state-of-the-art production facilities integrate sophisticated laser drilling systems, precision sequential lamination processes, and rigorous quality control measures to deliver superior HDI and microvia PCB solutions.

Our advanced manufacturing capabilities include:

- Laser drilling systems capable of producing microvias down to 75 micrometers diameter with exceptional positional accuracy

- Sequential lamination processes supporting complex buried and blind via configurations up to 20+ layers

- Controlled impedance via design and manufacturing with ±5% tolerance capability

- Advanced HDI stackup design optimization for high frequency applications

- Comprehensive electrical testing including TDR analysis and high frequency insertion loss measurement

- Statistical process control systems ensuring consistent via quality across production volumes

Our engineering team collaborates directly with customers during the design phase to optimize via selection and placement for specific high speed requirements, ensuring manufacturing compatibility while maximizing electrical performance.

Conclusion

Via design in high speed PCB applications represents a critical engineering discipline that directly impacts system performance, manufacturing cost, and product reliability. The selection between through-hole, blind, buried, and microvia technologies must consider electrical requirements, manufacturing capabilities, and cost constraints specific to each application.

Advanced via technologies including blind vias, buried vias, and microvias provide essential tools for managing signal integrity challenges in modern high frequency designs. The successful implementation of these technologies requires thorough understanding of electromagnetic principles, manufacturing processes, and design optimization techniques.

For organizations requiring sophisticated high speed PCB via design and manufacturing capabilities, partnering with experienced suppliers like Haoyue Electronics ensures access to advanced technologies and engineering expertise necessary for competitive product development in demanding applications.

Frequently Asked Questions

What is the difference between blind vias and buried vias in high speed PCB design?

Blind vias connect outer layers to internal layers without penetrating the entire board thickness, while buried vias exist completely within internal layers without reaching any surface. Blind vias are visible from one side of the PCB and help reduce via stub length, improving high frequency performance. Buried vias are completely internal and maximize surface routing area but require more complex sequential lamination processes during manufacturing.

How do microvias improve signal integrity compared to traditional through-hole vias?

Microvias offer significantly reduced parasitic inductance and capacitance due to their smaller diameter (typically <150μm) and shorter length. This reduction in parasitic effects minimizes impedance discontinuities, reduces via stub resonances, and improves high frequency signal transmission characteristics. The laser drilling process also enables precise positioning and consistent geometry, supporting better controlled impedance via design in high speed applications.

What are stacked versus staggered microvia configurations and when should each be used?

Stacked microvias align vertically through successive layer pairs, providing the shortest signal path but concentrating mechanical stress during thermal cycling. Staggered microvias offset laterally between layers, distributing stress more effectively and improving reliability but requiring additional routing length. Stacked configurations are preferred when signal path length is critical, while staggered designs are better for high-reliability applications with demanding thermal requirements.

How does via stub removal through back drilling benefit high speed PCB performance?

Via stub removal eliminates unterminated transmission line segments that create resonances and reflections at high frequencies. Back drilling in high speed PCB applications involves precisely removing unused via portions after plating, significantly improving insertion loss and return loss characteristics. This technique is particularly beneficial for signals that do not require full board penetration, allowing the use of through-hole via processes while achieving blind via performance benefits.

What manufacturing considerations affect microvia reliability in multilayer PCB applications?

Microvia reliability depends on proper copper plating thickness, appropriate aspect ratios (typically <1:1 for laser-drilled vias), and compatible material selections that minimize thermal expansion mismatches. Manufacturing quality control includes monitoring via barrel thickness uniformity, ensuring adequate copper coverage, and maintaining proper registration between sequential lamination cycles. Advanced HDI manufacturing processes also implement statistical process control to monitor via characteristics and ensure consistent electrical and mechanical performance across production volumes.