Single layer PCBs represent a fundamental technology in modern electronics, offering optimal solutions for applications requiring cost-effective, reliable circuit implementation. Understanding the various single layer PCB types enables engineers and designers to select the most appropriate substrate material and construction for their specific thermal, mechanical, and electrical requirements.

Understanding Single Layer PCB Architecture

Single layer PCBs feature conductive copper traces on one side of an insulating substrate, creating a simple yet effective circuit board design. This architecture differs significantly from multilayer PCBs, which incorporate multiple conductive layers separated by insulating materials. The single-sided design eliminates the complexity of via drilling and layer-to-layer interconnections, resulting in reduced manufacturing costs and simplified assembly processes.

The fundamental structure consists of a base substrate material, typically ranging from 0.8mm to 3.2mm in thickness, with copper traces etched on one surface. A soldermask layer protects the copper traces while exposing component pads for assembly. The substrate material selection determines the PCB’s thermal, mechanical, and electrical characteristics, making it the primary factor in defining single layer PCB types.

Rigid PCB

Rigid Single Layer PCB Types

FR-4 Glass Epoxy Single Layer PCBs

FR-4 glass epoxy represents the most widely used substrate material for rigid single layer PCBs. This flame-retardant fiberglass composite offers excellent mechanical strength, dimensional stability, and cost-effectiveness. The glass fiber reinforcement provides structural integrity while the epoxy resin delivers electrical insulation properties.

FR-4 single layer PCBs demonstrate superior performance in temperature ranges from -40°C to 130°C, making them suitable for standard electronics applications. The material’s low moisture absorption rate (less than 0.1%) ensures consistent electrical properties across varying environmental conditions. These boards excel in consumer electronics, industrial controls, and general-purpose applications where cost optimization is paramount.

Phenolic Paper Single Layer PCBs

Phenolic paper substrates offer an economical alternative for low-cost single layer PCB applications. Composed of paper reinforcement with phenolic resin, these boards provide adequate electrical insulation for simple circuits while maintaining affordability. The material’s lower glass transition temperature restricts operating temperatures to approximately 105°C.

Although phenolic paper PCBs exhibit reduced mechanical strength compared to FR-4, they remain suitable for educational projects, prototyping, and basic consumer electronics where cost constraints outweigh performance requirements. The material’s punching capabilities enable efficient fabrication of simple geometric shapes through mechanical processing.

CEM-1 Composite Single Layer PCBs

CEM-1 represents a hybrid substrate combining paper core with glass fiber surface layers. This construction provides enhanced mechanical properties compared to standard phenolic paper while maintaining cost advantages over FR-4. The glass fiber surfaces offer improved copper adhesion and reduced thermal expansion coefficients.

CEM-1 single layer PCBs demonstrate intermediate performance characteristics, making them suitable for applications requiring better mechanical properties than phenolic paper but not justifying FR-4 costs. These boards find applications in automotive electronics, basic industrial controls, and consumer appliances.

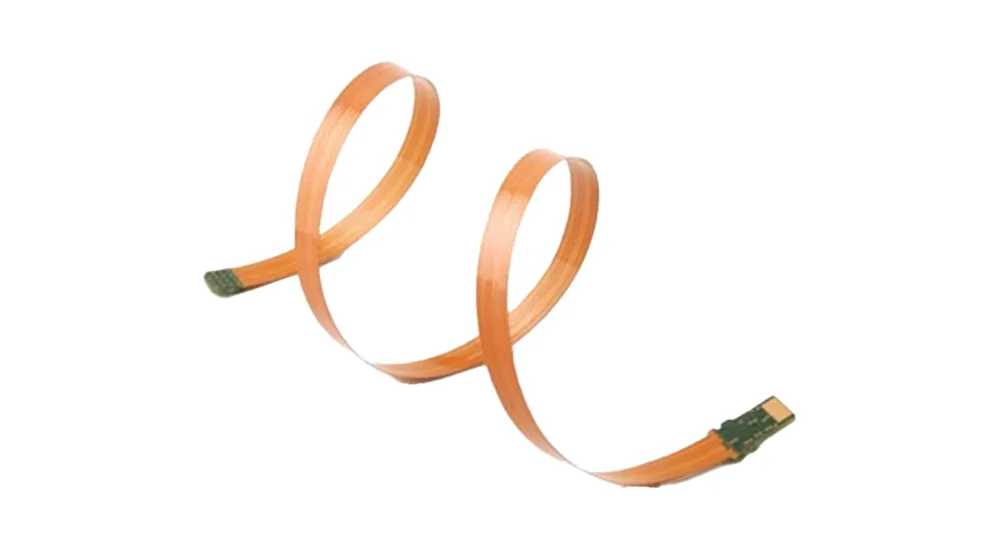

Flexible Single Layer PCB Types

Polyimide Flexible Single Layer PCBs

Polyimide flexible PCBs deliver exceptional flexibility and temperature resistance for applications requiring dynamic bending or complex three-dimensional installations. The polyimide substrate maintains electrical and mechanical integrity through repeated flexing cycles while operating in temperature ranges from -269°C to 260°C.

These flexible single layer PCBs demonstrate superior chemical resistance and low outgassing properties, making them ideal for aerospace, medical devices, and precision instrumentation. The material’s inherent flexibility eliminates the need for mechanical connectors in many applications, reducing system complexity and improving reliability.

PET Flexible Single Layer PCBs

Polyethylene terephthalate (PET) flexible PCBs offer cost-effective flexibility for applications with moderate temperature requirements. Operating effectively in ranges from -70°C to 105°C, PET substrates provide adequate performance for consumer electronics and basic flexible interconnections.

PET flexible single layer PCBs demonstrate good dimensional stability and chemical resistance while maintaining lower material costs compared to polyimide alternatives. These boards suit applications in wearable devices, simple flexible displays, and cost-sensitive consumer products.

Related Reading

· Essential Types of Flexible PCB

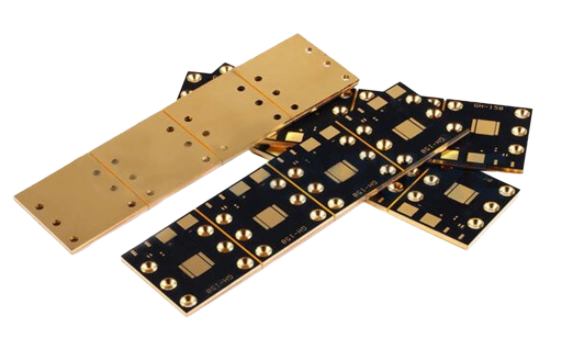

Metal Core Single Layer PCB Types

Aluminum Single Layer PCBs

Aluminum single layer PCBs excel in thermal management applications where efficient heat dissipation is critical. The aluminum substrate provides thermal conductivity approximately 5–8 times higher than standard FR-4, enabling effective heat transfer from components to the board surface for convective cooling.

The aluminum base thickness typically ranges from 1.0mm to 3.0mm, with a thin dielectric layer (0.1mm to 0.2mm) separating the copper traces from the metal core. This construction enables direct thermal coupling between heat-generating components and the aluminum substrate while maintaining electrical isolation.

Copper Single Layer PCBs

Copper single layer PCBs offer superior thermal conductivity compared to aluminum alternatives, with thermal conductivity values exceeding 400 W/mK. This exceptional thermal performance makes copper substrates ideal for high-power applications requiring maximum heat dissipation efficiency.

The copper base construction provides excellent electrical conductivity and electromagnetic shielding properties. However, the higher material cost and processing complexity limit copper single layer PCBs to specialized applications where thermal performance justifies the additional expense.

Ceramic Single Layer PCB Types

Alumina Ceramic Single Layer PCBs

Alumina ceramic substrates provide exceptional thermal stability and electrical insulation for high-temperature applications. With operating temperatures exceeding 1000°C, these single layer PCBs maintain stable electrical properties under extreme thermal conditions.

The alumina substrate demonstrates excellent chemical resistance and mechanical strength while offering thermal conductivity values of 20–30 W/mK. These characteristics make alumina ceramic PCBs suitable for aerospace applications, high-temperature sensors, and industrial heating systems.

Aluminum Nitride Single Layer PCBs

Aluminum nitride ceramic substrates combine high thermal conductivity (170–200 W/mK) with excellent electrical insulation properties. This unique combination enables efficient thermal management in high-power applications while maintaining electrical isolation between components.

Aluminum nitride single layer PCBs demonstrate superior thermal expansion matching with silicon semiconductors, reducing thermal stress in power electronic applications. The material’s high cost restricts usage to critical applications where thermal performance is paramount.

Specialized Single Layer PCB Types

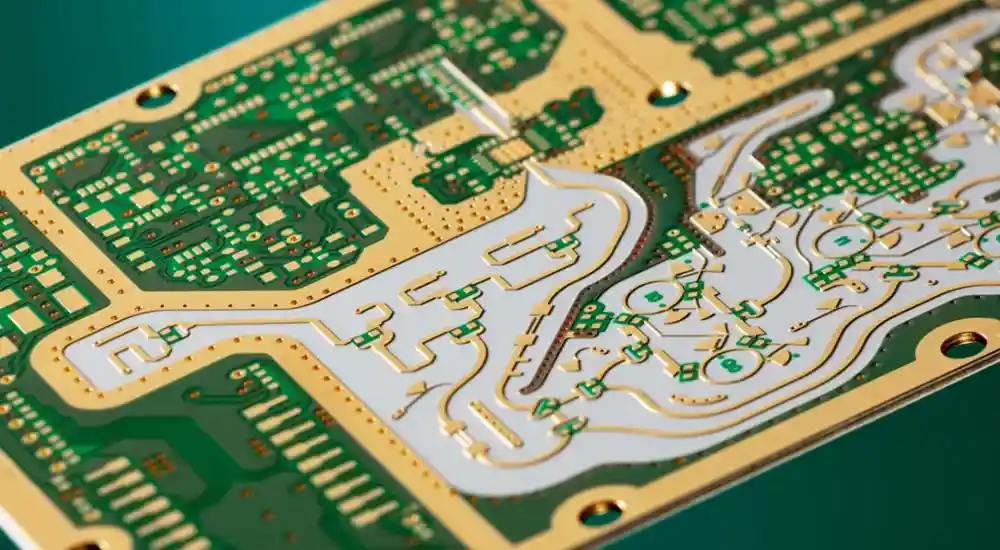

Rogers High-Frequency Single Layer PCBs

Rogers high-frequency laminates enable single layer PCB designs for RF and microwave applications. These specialized substrates offer controlled dielectric constants, low loss tangents, and stable electrical properties across wide frequency ranges.

Rogers materials such as RO4003C and RO4350B provide excellent dimensional stability and thermal performance for high-frequency single layer circuits. These substrates enable precise impedance control and minimize signal losses in RF applications.

PTFE Single Layer PCBs

Polytetrafluoroethylene (PTFE) substrates offer exceptional chemical resistance and low dielectric loss for demanding applications. PTFE single layer PCBs demonstrate stable electrical properties across wide temperature ranges while maintaining excellent chemical inertness.

The material’s low surface energy requires special processing techniques for copper adhesion, increasing manufacturing complexity. However, PTFE’s unique properties make it indispensable for chemical processing equipment and specialized electronic applications.

Applications and Industry Implementation

- LED Lighting: Aluminum single layer PCBs provide superior thermal management for efficient heat dissipation.

- Aerospace: Polyimide flexible PCBs offer lightweight, durable solutions ideal for complex and dynamic environments.

- Automotive:

- Ceramic substrates ensure reliable performance under high temperatures for sensor applications.

- Flexible substrates support dynamic installations and space-constrained designs.

- Consumer Electronics: FR-4 single layer PCBs remain the cost-effective choice for standard electronic devices.

- Power Electronics: Copper and aluminum single layer PCBs excel at managing heat in high-power systems.

- RF Applications: Specialized substrates deliver stable dielectric properties and low signal loss for RF circuits.

- Medical Devices: Biocompatible and flexible PCBs meet strict safety and interface requirements in medical equipment.

Manufacturing Considerations and Quality Control

Single layer PCB manufacturing requires careful consideration of substrate properties, copper adhesion, and thermal management. The simplified single-sided design reduces processing complexity while maintaining stringent quality requirements for electrical performance and reliability.

Thermal management becomes critical in metal core single layer PCBs, requiring precise control of dielectric thickness and thermal interface materials. Quality control procedures must address thermal conductivity measurement, electrical insulation testing, and mechanical strength verification.

Related Reading

· Single Layer PCB Manufacturing Process

Partner with Professional PCB Manufacturing Excellence

At Haoyue Electronics, we specialize in manufacturing high-quality single layer PCBs across all substrate types and applications. Our comprehensive capabilities include FR-4 rigid PCBs, polyimide flexible circuits, aluminum thermal management boards, and specialized ceramic substrates. Our experienced engineering team provides design optimization support to ensure your single layer PCB selection meets performance requirements while optimizing manufacturing costs.

Our advanced manufacturing facilities maintain strict quality control standards, including automated optical inspection, electrical testing, and thermal performance validation. Whether you require prototyping support or volume production, Haoyue Electronics delivers consistent quality and reliable delivery schedules. Contact our technical team today to discuss your single layer PCB requirements and discover how our expertise can enhance your next electronic product development.

FAQ

1. What are the different types of single layer PCBs and their common applications?

Single layer PCBs include rigid (FR-4, phenolic paper, CEM-1), flexible (polyimide, PET), metal core (aluminum, copper), ceramic (alumina, aluminum nitride), and specialized types (Rogers, PTFE). They are widely used across industries like consumer electronics, automotive, aerospace, medical, and LED lighting.

2. How to choose the right substrate material for single layer PCB manufacturing?

Choosing a substrate depends on factors such as thermal requirements, mechanical flexibility, electrical performance, cost, and application environment. For example, FR-4 suits general electronics, metal core PCBs excel in heat dissipation, and flexible PCBs are ideal for bending or space-constrained designs.

3. What quality control processes ensure reliable single layer PCB production?

Key quality controls include copper adhesion testing, automated optical inspection (AOI), electrical testing, and thermal performance validation. These measures help ensure consistent electrical reliability, mechanical strength, and proper heat management in final products.

4. What industries benefit most from single layer PCB technology?

Industries such as consumer electronics, automotive sensors, aerospace, medical devices, power electronics, and LED lighting heavily rely on single layer PCBs for cost-effective, reliable, and application-specific solutions.

5. Why partner with Haoyue Electronics for single layer PCB manufacturing?

Haoyue Electronics offers extensive expertise in diverse single layer PCB substrates, advanced manufacturing capabilities, strict quality control, and engineering support to optimize designs and costs, ensuring high-quality, on-time delivery for prototypes and volume production.