Understanding Rigid PCB Materials: Foundation for Electronic Design

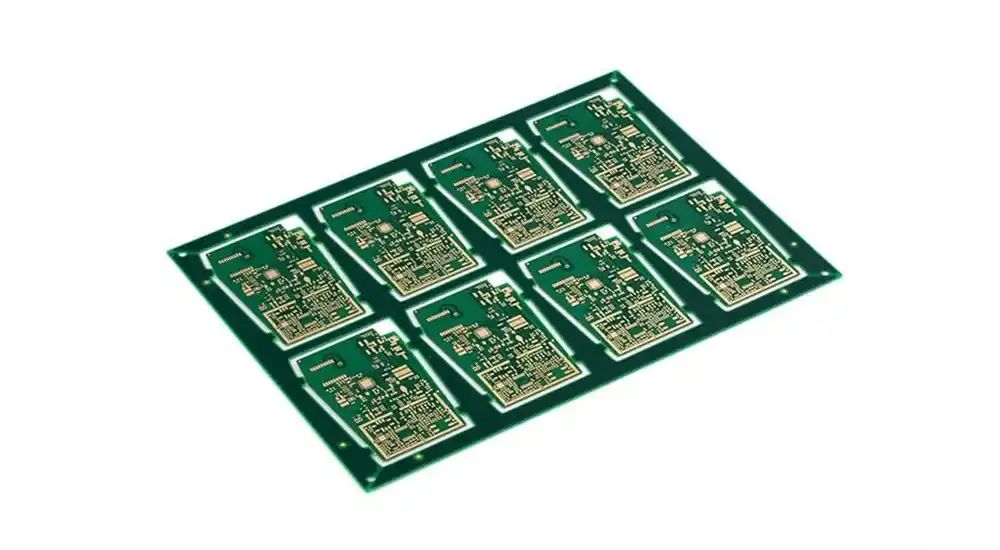

Rigid PCB materials serve as the foundational substrate for electronic circuits, providing mechanical strength, electrical insulation, and thermal management capabilities. Unlike flexible circuit boards, rigid substrates maintain their structural integrity across various operating conditions, making them ideal for applications requiring dimensional stability and robust electrical performance.

The choice of rigid PCB materials affects numerous design parameters including thermal conductivity, dielectric properties, mechanical strength, and overall system reliability. Different materials have unique functions and are well-suited for specific environments, with commonly used options including FR4, polyimide, metal-core materials, and ceramic substrates.

FR4: The Industry Standard for Rigid PCB Materials

Core Properties and Characteristics

FR4 stands for “Flame Retardant 4” and is composed of woven glass-reinforced epoxy resin, typically containing approximately 60% glass fabric and 40% epoxy resin by weight. This composite structure provides FR4 with its characteristic combination of mechanical strength, electrical insulation, and flame-retardant properties.

Standard FR4 materials offer a glass transition temperature (Tg) typically around 130°C to 140°C, making them suitable for general-purpose PCBs used in consumer electronics, industrial controls, and telecommunications equipment. The material’s widespread adoption stems from its excellent balance of performance characteristics and cost-effectiveness.

Applications and Industry Use Cases

FR4 demonstrates exceptional versatility across multiple industries. Its applications span consumer electronics like smartphones and laptops, automotive electronics for infotainment systems and engine control units, and industrial equipment including control systems and power supplies. This broad applicability makes FR4 the default choice for many electronic designs.

However, normal FR4 material, while offering good electrical insulation, is not ideal for high-frequency circuit boards. Engineers must consider these limitations when designing for specific performance requirements.

High-Performance Rigid PCB Materials

Polyimide Substrates for Demanding Applications

Polyimide materials are renowned for their excellent flexibility, superior thermal stability, and chemical resistance, capable of enduring temperatures up to 260°C. While primarily associated with flexible circuits, polyimide also serves as an excellent rigid substrate material for high-performance applications.

Polyimide flex materials offer inherent advantages over FR4 materials in controlled impedance applications, with lower dielectric constant values allowing for thinner cores and reduced overall thickness. The material maintains uniform properties without the discontinuities caused by woven glass matt found in rigid materials.

Cost-Performance Considerations

Polyimide PCB material costs generally range from $5 to $20 per square foot, depending on thickness and quality, representing a significant premium over FR4. Polyimide can cost 5-10 times more than FR4, but its durability and heat resistance justify the price for applications requiring these specific properties.

Ceramic Substrates: Premium Performance Solutions

Ceramic rigid PCB materials represent the pinnacle of thermal and electrical performance. Ceramic PCBs typically use aluminum nitride (AlN) or alumina materials, featuring excellent thermal conductivity, good electrical insulation, and low dielectric loss.

Aluminum Nitride (AlN) Properties

Aluminum Nitride PCBs offer incredible thermal conductivity (170 W/mK) and dielectric strength combined with low thermal expansion (CTE <4 ppm/C). AlN has significantly higher thermal conductivity compared to Alumina and FR4, making it ideal for applications requiring excellent heat dissipation.

These properties make AlN suitable for applications ranging from high-power LEDs and lasers to high-current switches and ultra-low temperature vacuum chamber electronics, including quantum computing applications.

Cost and Manufacturing Considerations

A simple PCB-to-PCB comparison shows that AlN circuits are more expensive than standard or even Rogers and metal core PCBs due to high material prices and lower panel sizes resulting in higher processing costs per piece. Ceramic PCB material costs typically range from $50 to $200 per square foot, significantly higher than FR4.

However, the better thermal properties of AlN can lead to simplification of the full module, potentially reducing the need for active cooling and decreasing total system costs.

Material Comparison and Selection Criteria

Thermal Performance Analysis

| Material | Thermal Conductivity (W/mK) | Operating Temperature Range | Applications |

|---|---|---|---|

| Standard FR4 | 0.3-0.4 | -40°C to 130°C | Consumer electronics, general purpose |

| High Tg FR4 | 0.3-0.4 | -40°C to 170°C | Automotive, industrial |

| Polyimide | 0.12-0.35 | -200°C to 260°C | Aerospace, high-temp applications |

| Aluminum Nitride | 170-180 | -55°C to 350°C | High-power LEDs, thermal management |

| Alumina | 18-36 | -55°C to 350°C | RF/microwave, high-frequency |

Electrical Properties and Performance

Polyimide materials demonstrate better dielectric constant (DK) values in the 3.2-3.4 range compared to standard FR4’s 4.0-4.4 DK. This lower dielectric constant enables superior high-frequency performance and controlled impedance applications.

The temperature rating differences are significant: FR4’s epoxy-based resin limits maximum operating temperature to the 150°C range, while polyimide reaches 300°C. This substantial difference makes material selection critical for high-temperature applications.

Mechanical Strength and Durability

Polyimide PCBs retain precise dimensions and structure despite temperature fluctuations, with dimensional stability exceeding traditional materials by factors of 5-10x, while rigid FR4 boards become distorted over typical operating ranges.

Polyimide demonstrates ability to withstand extreme mechanical stress such as physical strain as well as chemical and thermal exposure, making it favorable for automotive and aerospace industries where high endurance benefits are desired.

Industry-Specific Material Selection Guidelines

Automotive Electronics Applications

Automotive electronics require stability when subjected to extreme and repeated thermal cycling, applications where polyimide proves to work remarkably well. The material’s chemical resistance to oils, fuels, and automotive fluids provides additional reliability benefits.

For cost-sensitive automotive applications, high Tg FR4 materials offer improved temperature resistance while maintaining economic viability for volume production.

Aerospace and Defense Requirements

Polyimide PCBs demonstrate radiation resistance and high electrical properties, enabling more stable performance in aerospace applications from jet fighters to satellite systems. The material’s ability to function across extreme temperature ranges makes it essential for space applications.

Ceramic substrates find application in military radar systems and high-frequency communication equipment where thermal management and electrical performance are paramount.

High-Power LED and Thermal Management

Aluminum nitride substrates are used extensively in high-power LEDs and lasers due to their exceptional thermal conductivity and low thermal expansion. The copper/AlN hybrid PCB approach allows COB LEDs to be flip-chip bonded directly on AlN while maintaining cost-effective copper areas for other components.

Cost-Effectiveness Analysis and Decision Framework

Total Cost of Ownership Considerations

While premium materials command higher initial costs, total system cost analysis often reveals different conclusions. Superior thermal properties of advanced materials can enable simplified cooling solutions, potentially decreasing total electronics design costs.

For high power density or heat-sensitive designs in automotive and industrial LED lighting, aluminum and ceramic substrates offer superior heat dissipation, helping maintain system reliability and reducing the need for additional cooling components.

Volume Production Economics

Manufacturing volume plays a significant role in determining price per unit, with higher volumes often leading to lower prices due to economies of scale and better material utilization. Material selection must consider both prototype and production volume requirements.

Specialty materials often involve minimum order quantities, longer lead times, and smaller production panel sizes, factors that must be weighed against performance benefits.

Design Optimization Strategies

Material Selection Best Practices

Choose the most cost-effective substrate material that meets application requirements. Unless designs demand high-performance materials like polyimide, opting for standard FR4 can provide significant cost savings.

Engineers should evaluate thermal management requirements early in the design process. While aluminum and ceramic substrates are more expensive than FR4, they offer superior heat dissipation for demanding thermal conditions.

Manufacturing Considerations

Material selection based solely on datasheet performance can backfire if the material isn’t readily available or if suppliers lack proper certifications, potentially resulting in increased costs or project delays. Early supplier consultation ensures material availability and manufacturing compatibility.

Future Trends in Rigid PCB Materials

The electronics industry continues advancing toward higher performance and miniaturization. With increasing demand for high-speed, high-frequency, and high-temperature applications, adoption of advanced materials like low-loss substrates and thermally conductive materials is expanding.

Emerging hybrid approaches combine the cost-effectiveness of FR4 with high-performance materials in critical areas, optimizing both performance and economics. This approach enables designers to achieve required performance while managing material costs effectively.

Partner with Haoyue Electronics for Optimal Rigid PCB Solutions

At Haoyue Electronics, we understand that selecting the right rigid PCB materials is crucial for your product’s success. Our extensive experience in PCB manufacturing and assembly enables us to guide you through the material selection process, ensuring optimal performance while managing costs effectively.

Our engineering team works closely with clients to evaluate specific application requirements and recommend the most suitable rigid PCB materials, whether you need cost-effective FR4 solutions or high-performance ceramic substrates. We maintain comprehensive material capabilities and supplier relationships to support everything from prototype development to high-volume production.

Contact Haoyue Electronics today to discuss your rigid PCB material requirements and discover how our expertise can optimize your next electronic design project.

Frequently Asked Questions

1. When should I choose polyimide over FR4 for rigid PCB applications?

Polyimide becomes the preferred choice when applications require operating temperatures above 150°C, enhanced chemical resistance, or superior dimensional stability across temperature cycling. While more expensive than FR4, polyimide justifies its cost in aerospace, automotive engine compartment, and high-reliability applications where FR4 would fail.

2. Are ceramic PCB materials worth the premium cost for thermal management applications?

Ceramic materials like aluminum nitride provide exceptional thermal conductivity (170+ W/mK) compared to FR4 (0.3 W/mK), making them cost-effective for high-power applications despite higher material costs. The superior thermal performance often eliminates the need for additional cooling systems, reducing total system costs while improving reliability.

3. How do I balance performance requirements with material costs in rigid PCB design?

Conduct a total cost of ownership analysis that includes material costs, manufacturing complexity, thermal management requirements, and potential failure costs. Consider hybrid designs that use premium materials only in critical areas while utilizing cost-effective FR4 elsewhere. Early collaboration with PCB manufacturers helps optimize both performance and cost.

4. What are the key considerations for high-frequency rigid PCB material selection?

High-frequency applications require materials with low dielectric constant, minimal loss tangent, and stable electrical properties across frequency ranges. While FR4 works for lower frequencies, specialized materials like polyimide or ceramic substrates provide superior performance for RF and microwave applications, despite higher costs.