Both RF and Microwave PCBs handle high-frequency signals, but they operate in different frequency ranges and require distinct design approaches. The difference between RF and Microwave PCB extends beyond simple frequency boundaries to encompass material selection, design methodologies, and application-specific requirements.

Definition and Frequency Range Comparison

RF PCB Characteristics

RF PCBs typically operate within the frequency range of several MHz to approximately 6 GHz. This range encompasses most wireless communication applications, including WiFi, Bluetooth, cellular communications, and IoT devices. The RF PCB characteristics make them suitable for consumer electronics and commercial wireless applications.

Microwave PCB Specifications

Microwave PCBs generally handle frequencies from 6 GHz extending to 30+ GHz and beyond into millimeter wave territory. These circuits are essential for radar systems, satellite communications, 5G infrastructure, and automotive collision avoidance systems.

| Parameter | RF PCB | Microwave PCB |

|---|---|---|

| Frequency Range | MHz - 6 GHz | 6 GHz - 30+ GHz |

| Primary Applications | WiFi, Bluetooth, IoT | Radar, Satellite, 5G |

| Design Tolerance | Moderate | Very Strict |

| Material Cost | Lower | Higher |

Material Selection: RF PCB vs Microwave PCB Materials

Dielectric Constant and Loss Tangent Requirements

The choice of substrate materials represents one of the most critical differences between RF PCB design and Microwave PCB design. Material selection directly impacts signal integrity, insertion loss, and overall circuit performance.

RF PCB Material Options: Standard RF PCB materials include Rogers 4003C series, which offers a dielectric constant (Dk) of 3.38 with relatively stable temperature characteristics. For cost-sensitive RF applications below 2 GHz, modified FR-4 materials can sometimes suffice, though with performance compromises.

Microwave PCB Material Requirements: Microwave applications demand materials with extremely low loss tangent (Df) values, typically below 0.002. Rogers 4350B, Taconic TLY series, and Arlon materials become essential. These substrates maintain consistent dielectric properties across temperature variations and provide minimal signal attenuation at high frequencies.

Material Property Comparison

The dielectric constant stability becomes increasingly critical as frequency increases. RF PCB applications can often tolerate Dk variations of ±0.05, while Microwave PCB designs require Dk stability within ±0.02 or better.

Loss tangent requirements differ significantly between RF vs Microwave PCB frequency ranges. At 10 GHz, a loss tangent difference of 0.001 can result in 0.5 dB additional insertion loss per inch of transmission line length.

Temperature Coefficient Considerations: Microwave PCB materials must maintain stable electrical properties across wider temperature ranges. The temperature coefficient of dielectric constant (TCDk) becomes a primary selection criterion for applications experiencing thermal cycling.

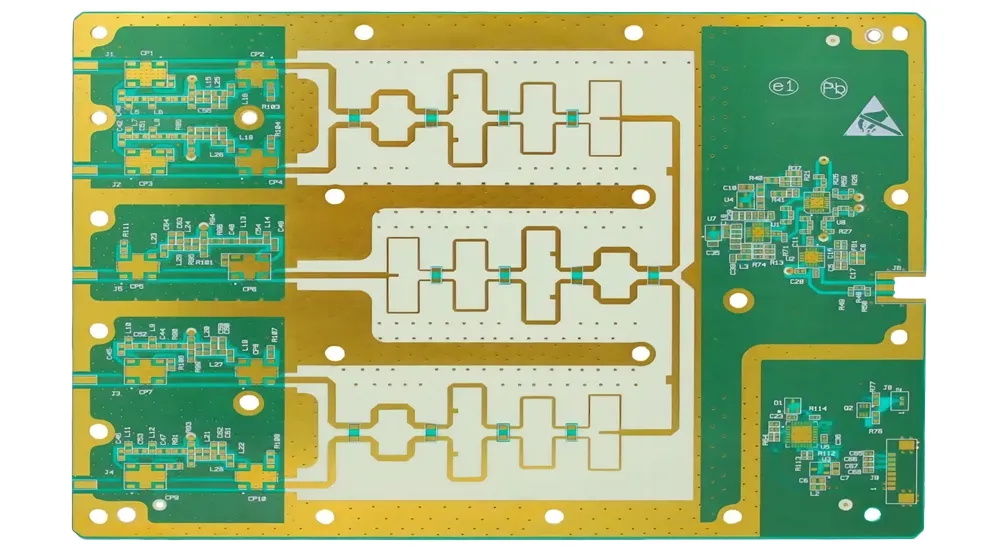

Microwave PCB

Design Requirements and Implementation Challenges

RF PCB vs Microwave PCB Design Complexity

RF PCB design typically focuses on impedance matching, basic EMI control, and component placement optimization. Standard microstrip and stripline configurations often provide adequate performance for most RF applications.

Microwave PCB design demands significantly more sophisticated approaches. The RF and Microwave PCB manufacturing challenges include precise control of trace geometry, via design optimization, and advanced simulation requirements.

Transmission Line Considerations

RF PCB Transmission Lines: Microstrip and stripline structures dominate RF PCB designs. These configurations provide good performance while maintaining reasonable manufacturing tolerances. Ground plane continuity and basic via stitching practices typically ensure adequate performance.

Microwave PCB Transmission Lines: Coplanar waveguides, grounded coplanar waveguides, and precision-controlled differential structures become necessary for Microwave applications. Via transitions require careful design to minimize parasitic effects that become significant at high frequencies.

Simulation and Modeling Requirements

RF PCB design often relies on basic S-parameter analysis and lumped-element modeling. Circuit simulators like ADS or AWR provide sufficient accuracy for most RF applications.

Microwave PCB design necessitates full electromagnetic simulation using tools capable of handling complex 3D field interactions. Method of Moments (MoM) and Finite Element Method (FEM) solvers become essential for accurate prediction of circuit behavior.

Application Areas: RF PCB vs Microwave PCB Applications

RF PCB Application Domains

Consumer electronics represent the primary market for RF PCBs. Wireless routers, smartphone RF sections, IoT sensors, and automotive keyless entry systems typically operate within RF frequency ranges. These applications prioritize cost-effectiveness while maintaining adequate performance.

Smart home devices, wearable technology, and industrial monitoring systems increasingly rely on RF PCB technology for wireless connectivity. The RF PCB design requirements for these applications focus on integration density and power efficiency.

Microwave PCB Application Sectors

Aerospace and defense applications drive much of the Microwave PCB market. Phased array radars, satellite communication systems, and electronic warfare equipment require the superior performance characteristics of Microwave PCBs.

The automotive industry increasingly adopts Microwave PCB technology for advanced driver assistance systems (ADAS). 77 GHz automotive radar systems for adaptive cruise control and collision avoidance represent growing application areas.

5G infrastructure development creates significant demand for Microwave PCBs. Massive MIMO antenna systems, beamforming networks, and millimeter wave base stations require the precision and performance that only specialized RF and microwave PCBs can provide.

Key Takeaways: RF PCB vs Microwave PCB Selection

The difference between RF PCB and Microwave PCB design primarily manifests in frequency range, material requirements, and design precision. RF PCBs excel in cost-sensitive applications below 6 GHz, while Microwave PCBs become necessary for higher frequency applications requiring superior performance.

Material selection represents the most significant cost and performance differentiator. RF applications can often utilize more economical substrates, while Microwave applications demand premium materials with exceptional electrical properties.

Design complexity and simulation requirements increase substantially when transitioning from RF to Microwave frequencies. The investment in advanced design tools and expertise becomes justified by the performance requirements of high-frequency applications.

Understanding these distinctions enables engineers to make informed decisions about technology selection, balancing performance requirements against cost constraints and manufacturing complexity.

Haoyue Electronics: Advanced RF & Microwave PCB Manufacturing

As these high-frequency applications become increasingly complex, selecting the right manufacturing partner becomes critical for project success. Haoyue Electronics specializes in both RF and Microwave PCB production, offering comprehensive capabilities for demanding high-frequency applications.

Our manufacturing expertise includes precision substrate handling for low-loss materials, controlled impedance fabrication with tight tolerances, and advanced via processing techniques essential for high-frequency performance. We maintain specialized equipment for handling Rogers, Taconic, and Arlon materials while ensuring consistent dielectric properties throughout the manufacturing process.

Key capabilities encompass HDI (High Density Interconnect) structures for compact RF designs, blind and buried via technology for complex multilayer configurations, and rigorous quality control procedures including time-domain reflectometry (TDR) testing for impedance verification.

For engineers developing next-generation RF and Microwave systems, Haoyue Electronics provides both manufacturing expertise and design for manufacturability consultation to optimize circuit performance while maintaining production efficiency.

Frequently Asked Questions

What is the main difference between RF PCB and Microwave PCB?

The primary distinction lies in frequency range and associated design requirements. RF PCBs typically handle frequencies up to 6 GHz, while Microwave PCBs operate from 6 GHz to 30+ GHz with more stringent material and design specifications.

Which materials are optimal for RF PCB vs Microwave PCB applications?

RF PCBs commonly use Rogers 4003C or modified FR-4 materials, while Microwave PCBs require low-loss materials like Rogers 4350B, Taconic, or Arlon substrates with superior dielectric stability.

How do RF and Microwave PCB manufacturing processes differ?

While basic fabrication processes remain similar, Microwave PCBs require tighter manufacturing tolerances, specialized substrate handling, and more rigorous quality control procedures to maintain high-frequency performance.

When should I choose Microwave PCB over RF PCB design?

Microwave PCB becomes necessary for applications above 6 GHz, radar systems, 5G infrastructure, or any application where signal integrity at high frequencies is critical to system performance.

Are RF PCB design principles applicable to Microwave PCB development?

Basic RF principles apply, but Microwave PCB design requires additional considerations for parasitic effects, advanced transmission line structures, and electromagnetic simulation techniques that become critical at higher frequencies.