Understanding RF PCB Materials Fundamentals

RF PCB substrate materials differ fundamentally from conventional PCB laminates in their molecular composition and electrical properties. These specialized materials are engineered to minimize signal degradation, reduce electromagnetic interference, and maintain consistent performance characteristics across temperature variations and mechanical stress conditions.

The primary distinction between standard PCB materials and RF-specific substrates lies in their dielectric composition. While conventional FR4 materials typically exhibit dielectric constants ranging from 4.2 to 4.8, high-frequency RF PCB materials maintain significantly lower values, typically below 4.0, enabling superior signal propagation characteristics essential for microwave and millimeter-wave applications.

Key Performance Indicators

Modern RF PCB material selection requires careful evaluation of multiple interconnected parameters. The relationship between dielectric constant stability, loss tangent characteristics, and thermal coefficient behavior determines the overall system performance across operational frequency bands. Understanding these relationships enables engineers to make informed material choices that optimize both electrical performance and manufacturing reliability.

Critical Electrical Properties for RF Performance

The electrical characteristics of RF PCB materials fundamentally determine circuit behavior across high-frequency operating conditions. This section provides detailed technical analysis of the primary electrical parameters that influence RF circuit performance.

Dielectric Constant Behavior and Frequency Response

The dielectric constant represents the ratio of a material’s permittivity to free space permittivity, directly affecting signal propagation velocity and characteristic impedance. In RF applications, dielectric constant stability across frequency ranges becomes critically important for maintaining consistent circuit behavior.

Advanced RF substrates exhibit dielectric constant variations typically within ±0.05 across their specified frequency range. This stability is achieved through carefully controlled resin chemistry and filler particle distribution. The frequency-dependent behavior follows predictable patterns, with most quality RF materials showing decreasing dielectric constants as frequency increases, following dispersion relationships that can be mathematically modeled for design purposes.

Temperature coefficient effects compound frequency-related variations. High-performance RF materials maintain dielectric constant stability within ±50 ppm/°C across operational temperature ranges. This thermal stability is achieved through specialized resin formulations that incorporate thermally stable cross-linking mechanisms and controlled filler particle interfaces.

Loss Tangent Mechanisms and Optimization

Loss tangent, or dissipation factor, quantifies the energy dissipated as heat during signal propagation through the dielectric medium. At high frequencies, molecular dipole relaxation and ionic conduction mechanisms contribute to energy losses that directly impact signal amplitude and system noise figure.

The physical mechanism underlying dielectric losses involves molecular alignment lag relative to alternating electric field changes. In high-quality RF substrates, this lag is minimized through optimized polymer chain structures and controlled cross-linking density. Premium RF materials achieve loss tangent values below 0.002 at 10 GHz through specialized resin chemistry and processing techniques.

Insertion loss performance directly correlates with loss tangent characteristics. For a typical 50-ohm transmission line, each 0.001 increase in loss tangent translates to approximately 0.1 dB additional insertion loss per inch at 10 GHz. This relationship emphasizes the critical importance of low-loss material selection for high-performance RF applications.

Impedance Control and Uniformity

Characteristic impedance uniformity across frequency ranges requires precise control of dielectric properties and geometric tolerances. High-frequency RF applications demand impedance variations within ±5% to maintain acceptable return loss performance. Achieving this level of control requires materials with exceptional dielectric constant uniformity and manufacturing processes capable of maintaining precise thickness tolerances.

The relationship between dielectric constant and characteristic impedance follows the fundamental transmission line equation, where impedance is inversely proportional to the square root of the effective dielectric constant. This relationship means that dielectric constant variations directly translate to impedance variations, making material uniformity critical for impedance-controlled designs.

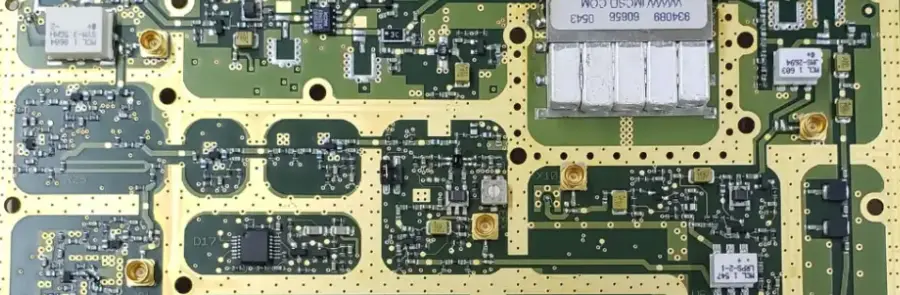

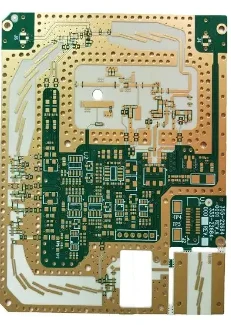

RF PCB

Leading RF PCB Material Manufacturers Comparison

The RF PCB materials market is dominated by several key manufacturers, each offering distinct advantages and specialized product portfolios tailored to specific application requirements.

Rogers Corporation Advanced Materials

Rogers Corporation maintains market leadership through comprehensive product lines spanning from entry-level to ultra-high-performance applications. The RO4000 series provides excellent balance between performance and processability, with RO4350B offering dielectric constant of 3.48 and loss tangent of 0.0037 at 10 GHz. The RT/duroid series delivers premium performance for demanding applications, with RT/duroid 5880 achieving loss tangent values as low as 0.0009 at 10 GHz.

Rogers materials excel in temperature stability and mechanical reliability. Their controlled dielectric constant temperature coefficients and dimensional stability make them preferred choices for aerospace and military applications where environmental extremes are encountered.

Taconic Advanced Dielectric Division

Taconic specializes in PTFE-based composites that deliver exceptional high-frequency performance. The TLX series combines low dielectric constant with outstanding dimensional stability, while the RF-35A2 provides cost-effective solutions for commercial applications with dielectric constant of 3.5 and loss tangent of 0.0025 at 10 GHz.

Taconic’s ceramic-filled PTFE formulations offer unique advantages for applications requiring thermal management capabilities. These materials combine low electrical losses with enhanced thermal conductivity, addressing both signal integrity and thermal design challenges simultaneously.

Arlon Materials for Electronics

Arlon focuses on specialty formulations for demanding applications, particularly in automotive radar and satellite communications. The 25N series delivers ultra-low loss performance with exceptional thermal stability. CuClad materials provide excellent copper adhesion characteristics essential for reliable manufacturing.

Arlon’s hydrocarbon-based formulations offer alternatives to PTFE systems while maintaining comparable electrical performance. These materials provide easier processing characteristics and improved cost-effectiveness for volume production applications.

FR4 Limitations in RF Applications

Standard FR4 materials face fundamental limitations in RF applications due to their higher dielectric constant (typically 4.2-4.8) and elevated loss tangent values (0.015-0.025 at 10 GHz). These characteristics result in increased insertion loss, reduced bandwidth, and compromised impedance control compared to specialized RF substrates.

However, advanced FR4 formulations have been developed for lower-frequency RF applications. These improved versions achieve loss tangent values below 0.008 and provide cost-effective solutions for applications below 5 GHz where premium RF materials may not be economically justified.

RF PCB Manufacturing

High-Frequency Application Material Selection Guidelines

Selecting optimal RF PCB materials for specific applications requires systematic evaluation of electrical requirements, environmental conditions, and manufacturing constraints.

Frequency Range Considerations

Applications operating below 1 GHz can often utilize high-performance FR4 variants or entry-level RF materials. The 1-10 GHz range typically requires dedicated RF substrates with loss tangent below 0.005 and stable dielectric constants. Applications above 10 GHz demand premium materials with loss tangent below 0.002 and exceptional dimensional stability.

Millimeter-wave applications above 30 GHz require ultra-low loss materials with specialized surface treatments to minimize conductor losses. At these frequencies, surface roughness effects become significant, necessitating smooth or reverse-treated copper foils to maintain acceptable insertion loss performance.

Environmental Requirements

Aerospace and military applications require materials with exceptional temperature stability, typically specified across -55°C to +150°C ranges. Automotive radar applications demand materials capable of withstanding thermal cycling and humidity exposure while maintaining electrical performance.

Commercial communications applications often prioritize cost-effectiveness while maintaining adequate performance margins. This balance typically favors materials offering good performance at moderate cost rather than premium materials with marginal performance advantages.

Design Rule Integration

High-frequency circuit designs require careful integration of material properties with geometric constraints. Via design becomes critical at high frequencies, with material selection affecting via aspect ratio limitations and reliability considerations. Stack-up design must account for material thickness availability and impedance control requirements across multiple layers.

Manufacturing Considerations for RF PCB Materials

RF PCB materials present unique manufacturing challenges that influence both material selection and process optimization strategies.

Processing Temperature Requirements

PTFE-based materials typically require elevated processing temperatures, often exceeding 280°C during lamination cycles. These temperature requirements affect both equipment capabilities and processing costs. Hydrocarbon-based alternatives often process at lower temperatures, reducing energy costs and expanding fabricator capabilities.

Thermal expansion matching becomes critical in hybrid stack-ups combining different material types. Careful selection of materials with compatible coefficients of thermal expansion prevents warpage and delamination during processing cycles.

Drilling and Machining Characteristics

Material composition directly affects drilling characteristics and tool wear rates. Ceramic-filled materials may require specialized tooling and reduced feed rates, increasing manufacturing costs. PTFE materials often require sharp tooling and controlled drilling parameters to prevent material smearing and hole quality issues.

Laser drilling compatibility varies significantly among RF materials. Some materials laser-drill effectively while others may require mechanical drilling or specialized laser parameters, affecting design flexibility and manufacturing costs.

Surface Finish Compatibility

RF applications often require low-loss surface finishes to minimize conductor losses at high frequencies. Material selection must consider compatibility with finishes such as immersion silver, ENIG, or OSP. Some RF materials may require specialized adhesion promoters or surface preparations for reliable finish adhesion.

Haoyue Electronics: Your RF PCB Manufacturing Partner

As the RF electronics industry continues advancing toward higher frequencies and more demanding applications, partnering with an experienced manufacturer becomes essential for project success. Haoyue Electronics combines advanced manufacturing capabilities with deep RF PCB materials expertise to deliver reliable solutions for high-frequency applications.

Our comprehensive RF PCB manufacturing capabilities encompass the complete spectrum of specialized substrates and advanced processing techniques required for today’s challenging RF designs. We maintain extensive experience with leading RF PCB materials from Rogers, Taconic, and Arlon, enabling optimal material selection for each specific application.

Core RF Manufacturing Capabilities

- Advanced Material Processing: Complete processing capabilities for PTFE, hydrocarbon, and ceramic-filled substrates across temperature ranges up to 300°C

- Precision Impedance Control: Maintained within ±5% through advanced process control and testing methodologies

- High-Frequency Testing: Comprehensive electrical testing capabilities extending beyond 40 GHz for validation of critical parameters

- Hybrid Stack-up Construction: Expertise in combining multiple RF material types while maintaining dimensional stability and electrical performance

- Low-Loss Surface Finishes: Specialized finishing processes optimized for minimal high-frequency conductor losses

- Assembly Integration: Complete PCB assembly services with RF component placement expertise and testing capabilities

Understanding that RF PCB material selection significantly impacts both performance and manufacturability, our engineering team provides comprehensive design for manufacturing support throughout the development process. This collaborative approach ensures optimal material selection while maintaining manufacturing efficiency and cost-effectiveness.