Fundamentals of RF PCB Design

RF PCB design differs significantly from standard digital circuit boards due to electromagnetic wave propagation effects. At high frequencies, circuit traces behave as transmission lines, making impedance control, signal routing, and ground plane design critical factors for optimal performance.

Key Design Considerations

Frequency Range Impact: Different frequency ranges present distinct challenges. Sub-GHz applications may tolerate conventional design approaches, while microwave PCB design above 10 GHz requires specialized techniques including controlled dielectric thickness and precise conductor geometry.

Electromagnetic Compatibility: RF circuits generate electromagnetic fields that can interfere with adjacent components. Proper shielding techniques, via placement, and ground plane continuity become essential design elements.

Power Handling: RF power amplifiers and transmitters generate significant heat, requiring thermal management considerations in both material selection and layout planning.

Critical RF PCB Materials Selection

The foundation of successful RF PCB design lies in appropriate material selection. Understanding dielectric properties, loss characteristics, and thermal behavior ensures optimal circuit performance across target frequency ranges.

Dielectric Constant Considerations

Stability Requirements: RF PCB materials must maintain consistent dielectric constant (Dk) across temperature variations and frequency ranges. Materials like Rogers RT/duroid series offer Dk stability within ±0.02 over temperature, crucial for filter and oscillator applications where frequency stability directly impacts system performance.

Frequency Dispersion: Standard FR-4 exhibits significant dielectric constant variation with frequency, making it unsuitable for precision RF applications above 1 GHz. Low-loss materials such as Rogers RO4003C maintain stable Dk values, enabling predictable impedance control in RF PCB materials applications.

Loss Tangent Impact

Signal Attenuation: Loss tangent (tan δ) directly affects signal attenuation in RF circuits. While FR-4 typically exhibits tan δ values of 0.02-0.025, specialized RF laminates achieve values below 0.002, reducing insertion loss by several dB over transmission line lengths.

Phase Noise Performance: Low loss tangent materials minimize phase noise in oscillator circuits. For applications requiring -140 dBc/Hz phase noise specifications, materials with tan δ below 0.001 become necessary.

Thermal Management Properties

Coefficient of Thermal Expansion: CTE matching between substrate and copper prevents thermal stress-induced failures. PTFE-based materials offer excellent thermal stability but require specialized manufacturing processes due to CTE mismatch with copper.

Thermal Conductivity: High-power RF applications benefit from thermally conductive substrates. Aluminum nitride and specialized ceramic-filled PTFE materials provide thermal conductivity values exceeding 2 W/m·K while maintaining low dielectric loss.

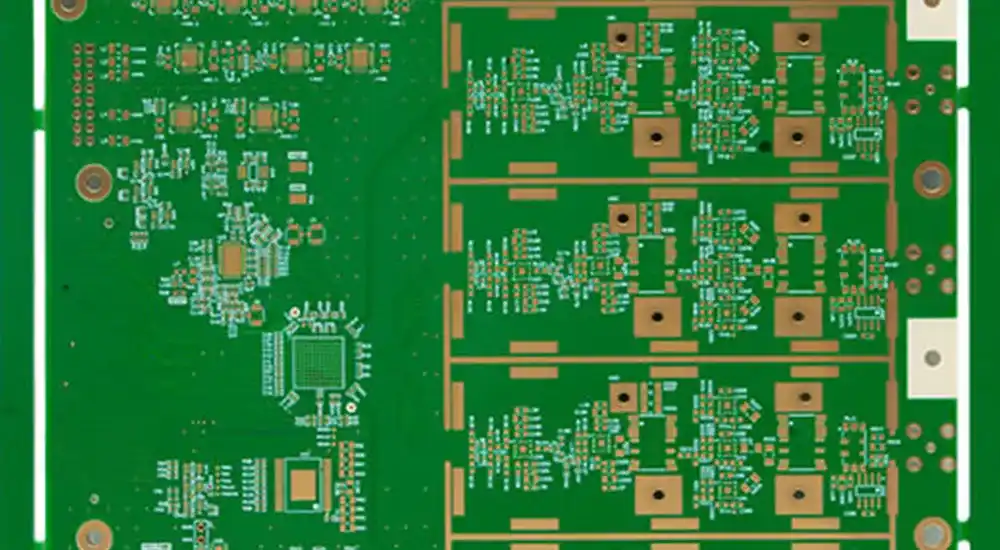

RF PCB

RF PCB Layout Optimization Techniques

Effective RF PCB layout requires systematic approach to trace routing, component placement, and electromagnetic field management. Poor layout practices can degrade circuit performance regardless of component quality or material selection.

Transmission Line Design

Impedance Control: Maintaining consistent characteristic impedance prevents signal reflections and maintains power transfer efficiency. Microstrip and coplanar waveguide geometries require precise width-to-height ratios, with manufacturing tolerances affecting impedance accuracy.

Via Transitions: Vertical interconnects introduce parasitic inductance and capacitance, affecting signal integrity. Proper via design includes controlled barrel diameter, anti-pad sizing, and ground via placement to maintain impedance continuity.

Ground Plane Architecture

Ground Continuity: Continuous ground planes provide low-impedance return paths for RF currents. Strategic via placement ensures ground connectivity between layers without creating resonant cavities that could interfere with circuit operation.

Ground Isolation: Sensitive analog circuits require isolated ground regions to prevent digital switching noise coupling. Star ground configurations and guard traces provide effective isolation while maintaining EMC compliance.

High Frequency PCB Stack-up Design Strategies

RF PCB stack-up design significantly impacts electrical performance, manufacturing yield, and cost optimization. Strategic layer arrangement enables controlled impedance routing while minimizing electromagnetic interference between circuit sections.

Layer Configuration Planning

Signal Layer Allocation: Dedicated RF signal layers positioned adjacent to ground planes ensure consistent impedance control and minimize crosstalk. Mixed-signal designs benefit from separating analog and digital routing layers with shielding planes.

Power Distribution: RF circuits require clean, low-noise power supplies. Dedicated power planes with appropriate decoupling capacitor placement provide stable voltages while minimizing supply-induced noise coupling.

Controlled Impedance Implementation

Manufacturing Tolerances: Achieving target impedance values requires collaboration between design and manufacturing teams. Prepreg thickness variations, copper weight tolerance, and etch factor affect final impedance values, necessitating process compensation in stack-up calculations.

Differential Signaling: Balanced RF signals require controlled differential impedance with tight coupling between trace pairs. Proper spacing and symmetric routing maintain common-mode rejection and minimize EMI radiation.

Signal Integrity Considerations in Microwave PCB Design

Microwave frequencies above 10 GHz present additional challenges requiring specialized design techniques. Wave propagation effects, parasitic coupling, and manufacturing precision become critical factors affecting circuit performance.

Electromagnetic Wave Effects

Wavelength Considerations: At microwave frequencies, circuit dimensions approach wavelength fractions, making distributed parameter effects dominant. Quarter-wave matching sections and stub tuning techniques become necessary design tools.

Surface Wave Propagation: Substrate modes can propagate parallel to the circuit surface, causing unwanted coupling between circuit elements. Proper substrate thickness selection and via fencing techniques suppress surface wave propagation.

Parasitic Mitigation Strategies

Component Parasitics: Surface-mount components exhibit significant parasitic reactances at microwave frequencies. Component selection must consider package parasitics, while layout optimization minimizes additional parasitic effects from pad geometry and via placement.

Coupling Mechanisms: Adjacent circuit elements can couple through electric and magnetic fields. Adequate spacing, shielding walls, and strategic ground via placement provide isolation while maintaining compact circuit dimensions.

Understanding RF PCB characteristics and addressing RF and microwave PCB manufacturing challenges ensures successful implementation of these signal integrity principles.

Haoyue Electronics: Your RF PCB Manufacturing Partner

Successful RF PCB design requires manufacturing expertise that bridges design intent with production reality. At Haoyue Electronics, we specialize in transforming complex RF designs into high-performance, production-ready circuit boards that meet demanding specification requirements.

Our RF PCB Capabilities

Our comprehensive manufacturing and assembly services address the unique challenges of RF and microwave PCBs:

- Advanced Material Processing: Expertise with Rogers, Taconic, and PTFE-based laminates

- Precision Impedance Control: ±5% tolerance on 50Ω and 75Ω transmission lines

- Microvia Technology: High-density interconnects for compact RF designs

- RF Assembly Services: Specialized handling of sensitive RF components

- Testing and Validation: Network analyzer verification and EMC pre-compliance testing

- Design Support: DFM optimization and electromagnetic simulation consultation

Our manufacturing processes incorporate specialized techniques for RF applications, including controlled-depth drilling for blind vias, precision etching for fine-line geometries, and thermal management solutions for high-power applications.

Whether you’re developing 5G infrastructure, satellite communications systems, or IoT wireless devices, our team provides the technical expertise and manufacturing precision required for successful RF PCB implementation.