Introduction

RF and Microwave PCB Cost represents a critical consideration for organizations developing high-frequency electronic systems, as these specialized circuit boards command significantly higher prices than conventional PCBs. Advanced materials like Teflon and ceramic-based PCBs increase production costs by 45%, limiting affordability for smaller manufacturers, while high-frequency PCB manufacturing costs are 50% higher than conventional PCB fabrication. Understanding the complex cost structure of RF and microwave PCBs enables engineers and procurement professionals to develop effective strategies that balance performance requirements with budget constraints while ensuring optimal signal integrity for applications ranging from 5G infrastructure to aerospace systems.

Key Factors Influencing RF and Microwave PCB Cost

Material Selection Impact

The substrate material represents the most significant cost driver in RF and microwave PCB manufacturing. Rogers materials, with lower dielectric losses (e.g., 0.0009 for Rogers 4350B), are ideal for RF and microwave circuits but cost 5-10 times more than standard FR-4. Material costs vary dramatically based on application requirements:

Standard Materials:

- FR-4: $0.10 to $0.50 per square inch

- Rogers materials: USD 20.00 to USD 75.00 per square inch—approximately 40-150 times the cost of basic FR-4

- Ceramic substrates: USD 2.00 to USD 10.00 per square inch

The selection between PTFE, ceramic-filled hydrocarbons, and specialized laminates directly correlates with frequency requirements and thermal performance specifications. Rogers materials like RT/duroid 5880, despite their higher cost, reduce power losses by 50%, ensuring high performance beyond 20 GHz.

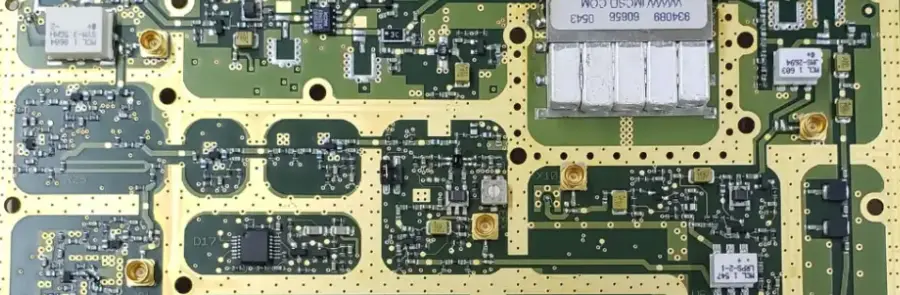

Manufacturing Complexity Premium

RF and microwave PCBs require specialized fabrication techniques that increase manufacturing costs substantially. 90% of RF PCBs require specialized fabrication techniques, increasing design complexity and limiting mass production capabilities. Critical manufacturing factors include:

Precision Requirements:

- Tighter impedance tolerances (±5% versus ±10% for standard PCBs)

- Enhanced copper surface finish for reduced skin effect losses

- Specialized drilling and plating processes for via structures

- Advanced lamination techniques for multi-layer stackups

Processing Overhead: The manufacturing complexity extends beyond material costs to include specialized equipment requirements, longer cycle times, and enhanced quality control procedures that contribute to the overall cost premium.

Design Specifications and Layer Count

Layer complexity significantly influences RF PCB pricing structures. Multi-layer RF designs require careful stackup engineering to maintain signal integrity while managing electromagnetic interference. Manufacturing cost can be decreased by using lesser processing steps. Often, this means reducing the number of layers and laminations.

The relationship between layer count and cost becomes exponential rather than linear for RF applications due to the precision required in each manufacturing step and the specialized materials used throughout the stackup.

Advanced Cost Optimization and Procurement Strategies

Strategic Material Selection Approach

Effective cost optimization begins with intelligent material selection that aligns performance requirements with budget constraints. If cost reduction is a priority, choose PTFE with ceramic coating, which requires a simpler fabrication process. Use laminates for outer layers and more economical epoxy glass laminates for inner layers for cost-effectiveness.

Hybrid Stackup Implementation: Modern RF PCB designs increasingly employ hybrid stackups that combine high-performance materials only where necessary. Critical RF signal layers utilize premium substrates while power distribution and digital control layers use standard materials, achieving substantial cost savings without compromising performance.

Frequency-Based Material Optimization: For frequencies less than 1 GHz, FR4 is recommended. For frequencies from 1 to 5 GHz, materials such as I-speed are suggested. For RF signals, special RF materials such as the Rogers 3000 series are suggested. This tiered approach ensures optimal performance-to-cost ratios across different frequency bands.

Volume-Based Procurement Strategies

The RF PCB market demonstrates significant economies of scale that procurement teams must leverage effectively. Category management has emerged as a cornerstone of effective procurement cost reduction in 2025. This approach involves grouping related products and services into distinct categories and developing tailored strategies for each.

Long-Term Supplier Partnerships: Establishing strategic relationships with specialized RF PCB manufacturers enables volume discounts, improved lead times, and priority allocation during supply constraints. 80% of PCB manufacturers have faced delays due to global supply chain issues, making reliable supplier relationships crucial for cost stability.

Consolidated Ordering Strategies: Coordinating RF PCB requirements across multiple projects allows organizations to achieve volume pricing tiers while reducing per-unit costs through economies of scale.

Design for Manufacturing (DFM) Cost Reduction

One of the best ways to reduce soft costs in PCB manufacturing is by using an early design review that can identify any potential design for manufacturing (DFM) or supply chain issues. DFM principles specifically tailored for RF applications include:

Standardization Initiatives:

- Implementing standard trace widths and spacing specifications

- Utilizing common via sizes and drilling patterns

- Standardizing substrate thicknesses across product lines

Manufacturing-Friendly Design Rules: From a cost optimization standpoint, your traces and spaces should be greater than 4.25 mils. This approach reduces manufacturing complexity while maintaining signal integrity requirements.

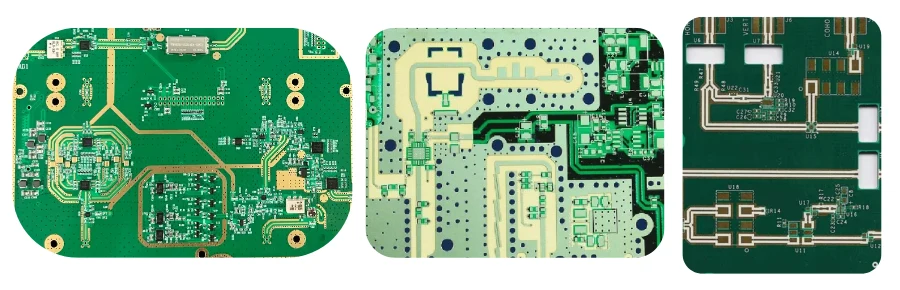

RF PCB

Industry-Specific Cost Considerations

Telecommunications and 5G Infrastructure

The telecommunications sector drives significant demand for cost-effective RF PCB solutions. Over 70% of telecom companies are upgrading infrastructure to accommodate high-speed 5G networks, driving demand for advanced RF PCBs. Cost considerations include:

Volume Production Requirements: 5G infrastructure deployments require substantial PCB quantities, enabling manufacturers to justify tooling investments and achieve competitive pricing through volume production.

Performance vs. Cost Balance: Telecommunications applications often require careful balance between cost constraints and performance specifications, particularly for consumer-grade equipment where market pricing pressures are intense.

Aerospace and Defense Applications

The defense sector has increased RF PCB integration by 40%, particularly for radar and satellite communications. Defense applications typically justify premium costs through:

Reliability Requirements: Military and aerospace applications demand enhanced reliability specifications that justify premium material costs and specialized manufacturing processes.

Low-Volume, High-Mix Production: Defense contracts often involve smaller quantities with higher complexity, resulting in different cost structures compared to commercial applications.

Automotive Electronics

ADAS-equipped vehicles have surged by 65%, driving demand for RF PCBs in radar, sensors, and communication modules. Automotive cost considerations include:

Automotive Qualification Costs: Meeting automotive industry standards (AEC-Q100) adds qualification and testing costs that must be factored into total cost of ownership calculations.

Temperature and Environmental Requirements: Automotive RF PCBs must withstand extreme temperature variations and environmental conditions, requiring specialized materials that increase costs.

Selecting the Right RF PCB Manufacturing Partner

Technical Capability Assessment

Choosing an appropriate RF PCB manufacturer requires comprehensive evaluation of technical capabilities beyond basic cost comparisons. Key evaluation criteria include:

Frequency Range Expertise: Manufacturers must demonstrate proven capabilities across required frequency ranges, from MHz applications to millimeter-wave frequencies above 30 GHz.

Material Handling Capabilities: Experience with specialized substrates including Rogers, Taconic, and ceramic materials is essential for consistent quality and yield optimization.

Quality and Reliability Verification

Understanding the link between 2025 PCB cost-driving factors and quality is imperative. The old motto goes, “Do it right, or do it twice (or sometimes more)”. Quality assessment should include:

Process Control Systems: Manufacturers should demonstrate robust process control systems including statistical process control (SPC) and real-time impedance monitoring.

Testing and Validation Capabilities: Comprehensive testing capabilities including network analyzer measurements and environmental stress testing ensure reliable performance.

Conclusion

Effective management of RF and Microwave PCB cost requires a comprehensive understanding of material properties, manufacturing complexities, and strategic procurement approaches. Organizations can achieve substantial cost reductions through intelligent material selection, design optimization, and strategic supplier partnerships while maintaining the performance characteristics essential for high-frequency applications.

The evolving landscape of RF and microwave technologies, driven by 5G deployment and IoT expansion, presents both challenges and opportunities for cost optimization. Success requires balancing immediate cost pressures with long-term performance requirements while leveraging emerging materials and manufacturing technologies to achieve competitive advantages.

Haoyue Electronics: Your Trusted RF PCB Manufacturing Partner

At Haoyue Electronics, we understand the critical balance between RF and Microwave PCB cost and performance requirements. Our comprehensive manufacturing and assembly capabilities position us as the ideal partner for organizations seeking cost-effective RF PCB solutions without compromising quality.

Our Core Capabilities:

- Advanced substrate handling including Rogers, Taconic, and ceramic materials

- Precision impedance control with ±5% tolerance capability

- Multi-layer stackup design optimization for cost and performance

- High-frequency testing and validation up to 40 GHz

- DFM consultation services to optimize designs for manufacturability

- Flexible volume production from prototypes to high-volume manufacturing

- ISO 9001:2015 and IPC Class 3 certification for quality assurance

Our experienced engineering team works closely with clients to implement cost optimization strategies while maintaining the signal integrity and reliability requirements essential for RF and microwave applications. Contact Haoyue Electronics today to discuss how our expertise can reduce your RF PCB costs while delivering superior performance.

Frequently Asked Questions

How to reduce RF PCB cost without compromising performance?

The most effective approach to reducing RF PCB manufacturing cost involves strategic material selection and design optimization. Implement hybrid stackups using premium materials only for critical RF layers while utilizing standard substrates for power and digital sections. For frequencies less than 1 GHz, FR4 is recommended, enabling significant cost savings for lower-frequency applications. Additionally, standardizing trace widths above 4.25 mils reduces manufacturing complexity and associated costs.

What factors contribute most to RF PCB materials cost comparison?

Material costs represent the primary cost driver in RF PCB manufacturing, with Rogers materials commanding USD 20.00 to USD 75.00 per square inch—approximately 40-150 times the cost of basic FR-4. The dielectric constant, loss tangent, and thermal properties directly influence material pricing. PTFE-based substrates offer superior electrical performance but command premium pricing, while ceramic-filled hydrocarbons provide a middle-ground solution for cost-sensitive applications.

How can organizations find low-cost RF PCB manufacturing options?

Identifying cost-efficient RF PCB manufacturing requires evaluating suppliers based on technical capabilities, volume pricing structures, and geographic advantages. Category management has emerged as a cornerstone of effective procurement cost reduction in 2025. Establish long-term partnerships with specialized manufacturers to access volume discounts and priority allocation. Consider manufacturers with hybrid material capabilities and DFM expertise to optimize designs for cost-effective production.

Which RF PCB supplier strategies ensure cost efficiency?

Effective RF PCB supplier selection focuses on total cost of ownership rather than initial pricing. Evaluate suppliers based on yield rates, quality consistency, and technical support capabilities. VSE works alongside design teams to address these issues upfront expeditiously, ensuring all aspects of production proceed smoothly. Suppliers offering DFM consultation and design optimization services provide additional value by reducing overall project costs through improved manufacturability.

What procurement strategies work best for high-frequency PCB cost optimization?

Successful procurement strategies for high-frequency PCBs combine volume consolidation, strategic timing, and supplier diversification. Implement contract lifecycle management (CLM) to transform static contracts into dynamic, data-rich assets that drive strategic insight and operational efficiency. Coordinate purchasing across multiple projects to achieve volume pricing tiers while maintaining supplier competition. Early engagement in the design process enables cost optimization through material selection and manufacturing process optimization.