Full-Service PCB Manufacturing for Prototypes to Mass Production

Looking for a trusted PCB manufacturer? We offer rigid, flex, HDI, and metal core PCBs with fast delivery, IPC standards, and competitive pricing.

PCB Manufacturing

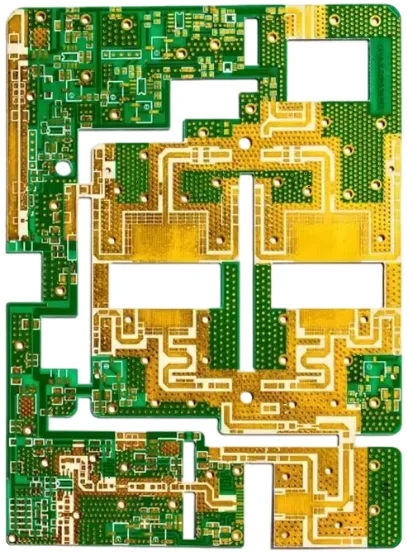

PCB Types We Manufacture — From HDI to Heavy Copper, Rigid-Flex and More

As a professional PCB board manufacturer, we specialize in producing a wide variety of printed circuit board types to meet diverse customer needs, from high-speed digital applications to rugged industrial environments. Our manufacturing capabilities are designed to support both high-complexity circuit board production and cost-effective standard PCBs.

We Offer the Following PCB Types:

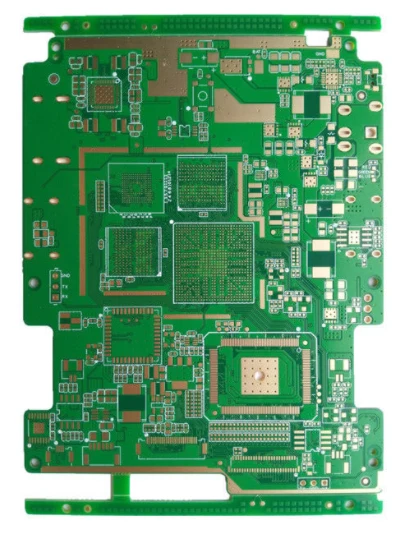

- Multilayer PCBs: Up to 40 layers, ideal for complex systems like servers, medical imaging, and high-end computing.

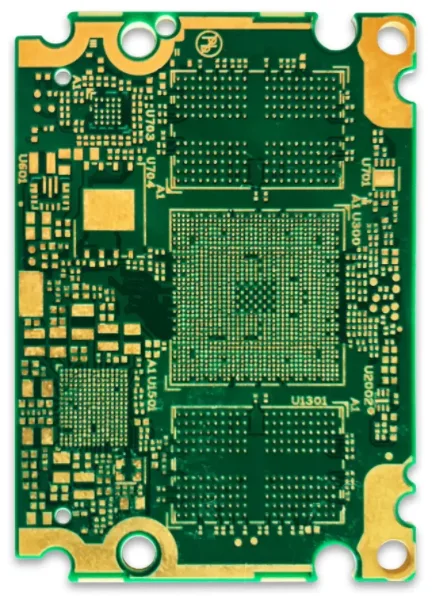

- High-Density Interconnect (HDI) PCBs: Featuring 2.5/2.5mil trace/space, laser microvias, and 1:1 aspect ratio, perfect for smartphones, wearables, and miniaturized electronics.

- Heavy Copper PCBs: Up to 20oz copper for both inner and outer layers, used in power supply systems, EVs, and industrial controls.

- Rigid-Flex PCBs: Combines flexibility and structural integrity, commonly used in aerospace, medical devices, and military-grade electronics.

- Aluminum & Metal Core PCBs: Excellent for heat dissipation in LED lighting and power modules.

- Impedance-Controlled PCBs: Tightly managed impedance with ±5Ω tolerance for ≤50Ω lines, ensuring signal integrity in high-speed circuits.

- Ultra-Thin PCBs: Board thickness as low as 0.4mm, ideal for compact and portable electronics.

- Custom PCBs: Including ceramic, black core, and high-frequency PCBs with premium materials like Rogers, Taconic, and PTFE.

From standard 2-layer boards to complex HDI structures, we provide reliable, high-quality PCB board fabrication tailored to your design and performance requirements.

One-Stop PCB Manufacturing – From Prototypes to Mass Production

Multilayer, HDI, Heavy Copper, Rigid-Flex – All Types, All Industries

Precision Fabrication – 2/2mil Lines, ±5Ω Impedance Control, 1:1 Aspect

Built for Performance – From Automotive Power to 5G Signal Integrity

Certified Quality – 100% Electrical Testing, IPC Class 2/3, RoHS & ISO

Premium Materials – Rogers, Taconic, PTFE, Black Core, and Ceramics

PCB Solutions

Comprehensive PCB Solutions, Built for Your Needs

Rigid PCBs – Reliable, Cost-Effective, and Ready for Scale

Looking for stable performance, affordable pricing, and fast production? Our rigid PCBs are built for high-reliability applications and cost-sensitive projects alike—from consumer electronics to industrial controls.

Why engineers choose our rigid PCBs:

- ✔ Tight dimensional control for precise assembly and automated soldering

- ✔ Multilayer stack-ups (up to 50 layers) with impedance control

- ✔ Excellent planarity—ideal for fine-pitch components and BGAs

- ✔ Material options beyond standard FR4: high-Tg, halogen-free, high-frequency-compatible

- ✔ Quick-turn prototyping to full-scale production with consistent quality

- ✔ 100% electrical testing and AOI for every board

Typical Use Cases:

- Industrial controls & automation

- Power modules & converters

- Set-top boxes & home appliances

- Medical instrumentation (non-flex areas)

Need stack-up suggestions or thermal design tips for high-power sections? Our engineers are here to help.

Flex PCBs – Ultra-Thin, Bendable, Built for Tight Spaces

Flex PCBs solve space and weight challenges in today’s compact devices. Designed on polyimide substrates, they offer tight bend radii, dynamic flexing capability, and high vibration resistance—perfect for wearables, cameras, and medical probes.

What makes our flex PCBs different:

- ✔ Ultra-thin core material (down to 25µm)

- ✔ 1-12 layers with custom stack-up options

- ✔ Dynamic and static bending designs

- ✔ ENIG, ENEPIG, and hard gold surface finishes

- ✔ Cleanroom manufacturing for sensitive applications

Used in:

- Foldable phones, smartwatches, and cameras

- Medical devices (catheters, sensors)

- Aerospace systems with weight constraints

- Automotive clusters and infotainment

We support both flex-to-install and dynamic-flex applications, with full DFM guidance available.

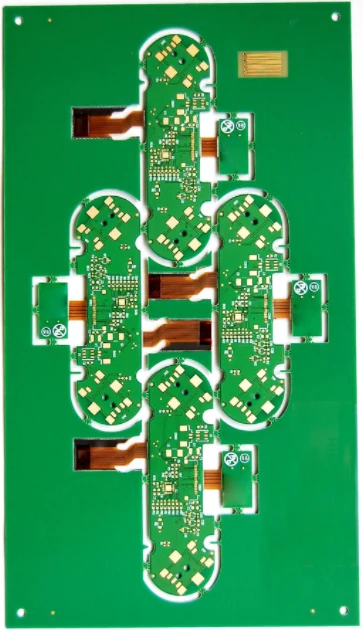

Rigid-Flex PCBs – Precision Integration of Structure and Flexibility

Rigid-Flex PCBs combine the best of both worlds: rigid sections for structural strength and flex regions for connectivity across moving parts or tight 3D shapes. They’re ideal for eliminating connectors and improving system reliability.

Why choose our rigid-flex solutions:

- ✔ Controlled impedance routing through both flex and rigid zones

- ✔ Stack-ups up to 30 layers (e.g., 4R–2F–4R)

- ✔ Laser-drilled microvias and via-in-pad support

- ✔ Seamless rigid-to-flex transitions for reduced stress

- ✔ IPC 6013 Class III capable manufacturing

Typical Applications:

- Foldable consumer electronics

- Military and aerospace navigation systems

- Medical imaging and surgical tools

- Compact camera modules and sensors

Rigid-flex saves space and weight—ask us about replacing connectors in your current design.

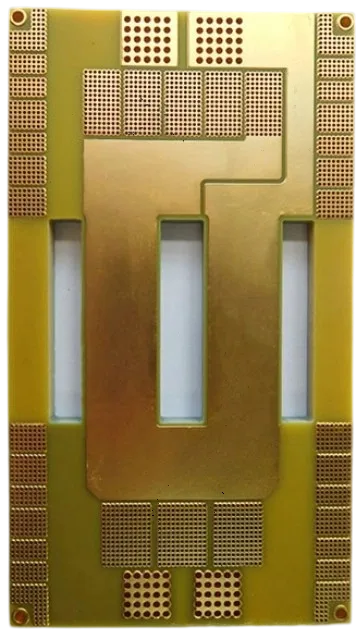

Metal Core PCBs (MCPCBs) – Built to Manage Heat, Built to Last

When thermal performance can’t be compromised, metal core PCBs deliver. With aluminum or copper cores, these boards excel in high-power, heat-sensitive applications like LED lighting and power converters.

Key advantages of our MCPCBs:

- ✔ 1- to 6-layer designs with aluminum or copper base

- ✔ Superior thermal conductivity (up to 3.0 W/m·K)

- ✔ Direct thermal path designs for power devices

- ✔ Metal back-drilling and countersink options

- ✔ White, black, or custom solder mask colors

Best fit for:

- High-power LED modules

- Motor control and power conversion

- Telecom base stations

- Automotive lighting and chargers

We support hybrid stack-ups—metal core base with FR4 routing layers above.

HDI PCBs – Compact, Fast, and High-Speed Ready

High Density Interconnect (HDI) PCBs enable tighter layouts, higher speeds, and miniaturization without sacrificing performance. Ideal for demanding digital and RF designs.

Our HDI manufacturing strengths:

- ✔ Microvia, blind/buried via, and via-in-pad support

- ✔ 2.5/2.5 mil line/space, 4 mil laser vias

- ✔ Stack-up types: 1+N+1 to 6+N+6

- ✔ Controlled impedance and low Dk materials

- ✔ High layer count (up to 40 layers) for complex systems

Commonly used in:

- Smartphones, tablets, and laptops

- RF/wireless modules

- Automotive ADAS systems

- Medical diagnostic equipment

Ask about sequential lamination, stacked vias, and high-speed stack-ups with low loss materials.

Heavy Copper PCBs – Built for High Power & Harsh Loads

When your design calls for high current, thermal resilience, or mechanical strength, heavy copper PCBs are the go-to solution. Used in industrial, energy, and automotive systems that push the limits.

Capabilities that set us apart:

- ✔ Up to 20oz copper outer layers

- ✔ 10oz inner layer copper in multilayer stack-ups

- ✔ Selective heavy copper regions (e.g., power zones only)

- ✔ Thermal relief and thick trace routing design support

- ✔ Compatible with press-fit and high-amp connectors

Applications include:

- Power converters and battery management

- Motor drives and solar inverters

- Electric vehicle charging systems

- Industrial robotics and automation

Need help balancing copper thickness with thermal relief? Our engineers assist with every layout stage.

High-Frequency PCBs – Precision Signal Integrity at GHz Speeds

High-frequency PCBs are critical in RF and high-speed digital systems. Our expertise ensures minimal signal loss, controlled impedance, and consistent performance across layers—even at 5G+ frequencies.

Advanced RF capabilities:

- ✔ Materials in stock: Rogers 4350B, 4003C, Panasonic M6, Isola I-Speed, MT40

- ✔ Tight Dk/Df control for predictable signal behavior

- ✔ Hybrid stack-ups: mix high-frequency and FR4 layers

- ✔ Laser-drilled vias and low-profile copper

- ✔ Designed for EMI shielding and grounding optimization

Used in:

- 5G telecom and radar systems

- RF modules, antennas, and filters

- Satellite and aerospace communications

- High-speed backplanes and test equipment

We provide material selection support, stack-up simulations, and impedance calculators to guide your design.

PCB-PCBA-EMS

From Concept to Completion — Your Trusted PCB Manufacturing Partner

At Haoyue Electronics, we’re more than just a PCB board manufacturer — we’re your long-term partner for innovation, quality, and scale. Whether you’re building a prototype or scaling into full production, our capabilities cover every stage of your printed circuit board journey.

What sets us apart:

- 15+ years of experience in multilayer, RF, HDI, and metal-core PCBs

- Turnkey PCB assembly with in-house SMT, DIP, and testing

- Engineering-driven DFM support and custom stack-up consulting

- Fast lead times, flexible MOQs, and global logistics

- IPC Class 2/3, ISO 9001, UL, and RoHS-certified processes

No matter the complexity or application, we help bring your PCB project to life — with precision, speed, and reliability.

Trusted PCB Partner from China

- 100% Genuine Taconic & Rogers PCB Materials

- Expert in RF, Microwave, and High-Frequency 5G PCB Fabrication

- Fast Turnaround – Prototypes Ready in 3–5 Business Days

- Global Delivery with Multilingual Technical Support

- OEM & ODM Ready – From PCB Design to Full Product Assembly

- Proven Experience in Aerospace, Medical Devices, and Telecom Applications