Glass transition temperature (Tg) defines the thermal threshold at which epoxy resin transitions from a rigid, glassy state to a softer, rubbery condition. This fundamental property directly influences mechanical stability, dimensional accuracy, and long-term reliability of FR4 printed circuit boards under operational stress.

Understanding Glass Transition Temperature in FR4 Materials

The glass transition temperature serves as a crucial parameter for determining substrate suitability across various operating environments. Standard FR4 materials typically exhibit Tg values ranging from 130°C to 140°C, while High Tg FR4 variants exceed 170°C, with some premium grades reaching 180°C or higher.

This temperature differential becomes critical during PCB assembly processes, particularly lead-free soldering operations that require peak temperatures of 260°C. The substrate must maintain dimensional stability and mechanical integrity throughout multiple thermal cycles while preserving electrical characteristics.

Thermal Behavior Under Operating Conditions

FR4 substrates undergo measurable property changes as temperatures approach their glass transition point. Below Tg, the material maintains excellent mechanical strength, low coefficient of thermal expansion, and stable electrical properties. Beyond this threshold, thermal expansion increases dramatically, potentially causing delamination, warpage, and compromised plated through-hole reliability.

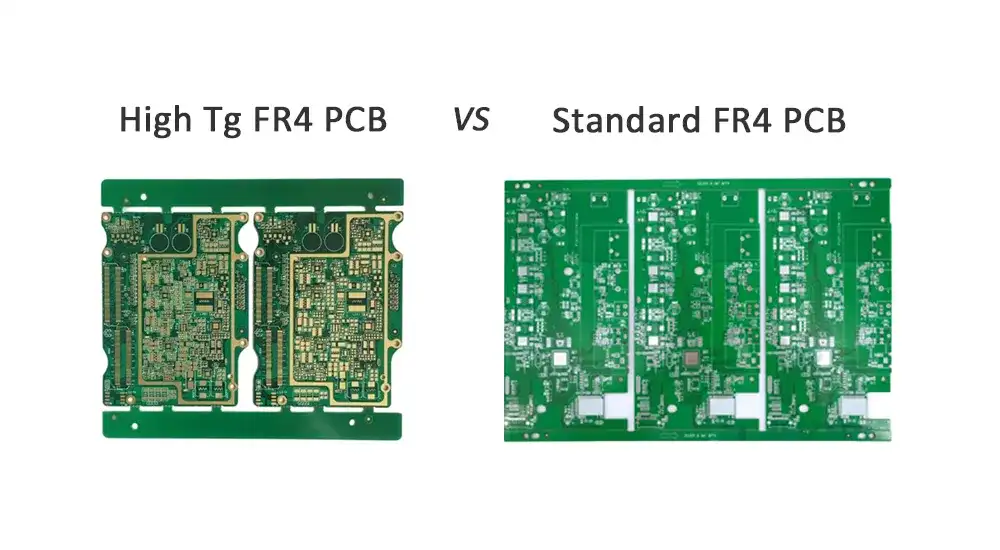

High Tg FR4 vs Standard FR4: Comparative Analysis

The performance distinction between High Tg and Standard FR4 becomes apparent through detailed material property comparison. High Tg FR4 demonstrates superior thermal stability, reduced moisture absorption, and enhanced chemical resistance compared to conventional FR4 substrates.

Mechanical and Thermal Properties

High Tg FR4 maintains structural integrity at elevated temperatures where Standard FR4 begins exhibiting mechanical degradation. The enhanced thermal performance translates to improved dimensional stability during assembly and operation, critical for high-density interconnect (HDI) and multilayer PCB manufacturing.

Thermal expansion characteristics differ significantly between these materials. Standard FR4 exhibits coefficient of thermal expansion values that increase substantially above Tg, while High Tg variants maintain more consistent expansion rates across broader temperature ranges.

Chemical and Environmental Resistance

High Tg FR4 formulations incorporate advanced epoxy systems that provide superior resistance to chemical degradation, moisture absorption, and environmental stress. This enhanced durability proves essential for applications requiring extended operational lifespans or exposure to challenging environmental conditions.

The improved chemical resistance also benefits PCB manufacturing processes, reducing material degradation during etching, drilling, and plating operations while maintaining consistent electrical properties throughout production.

Application Scenarios for Each FR4 Type

Standard FR4 remains the preferred choice for cost-sensitive applications operating within moderate temperature ranges. Consumer electronics, basic telecommunications equipment, and general-purpose industrial controls typically function effectively with Standard FR4 substrates.

High Tg FR4 becomes essential for applications demanding superior thermal performance. Automotive electronics, aerospace systems, high-power LED drivers, and telecommunications infrastructure require the enhanced thermal stability that High Tg materials provide.

Power Electronics and Thermal Management

Power conversion circuits, motor drives, and switching power supplies generate substantial heat during operation. High Tg FR4 enables more compact designs by maintaining reliability at elevated temperatures, reducing the need for extensive thermal management solutions.

The superior thermal properties allow designers to achieve higher power densities while maintaining acceptable operating margins, particularly critical in space-constrained applications where thermal dissipation options are limited.

Design Considerations and Material Selection

Selecting between High Tg and Standard FR4 requires careful evaluation of operating conditions, reliability requirements, and cost constraints. The decision process should consider peak operating temperatures, thermal cycling frequency, environmental exposure, and expected product lifespan.

Temperature Derating Guidelines

Industry best practices recommend maintaining operating temperatures at least 20°C to 25°C below the substrate Tg value. This derating ensures adequate safety margins and prevents thermal degradation throughout the product lifecycle.

For applications with peak operating temperatures approaching 130°C, High Tg FR4 becomes necessary to maintain this safety margin. Standard FR4 suffices for applications with maximum temperatures below 100°C to 110°C.

Manufacturing Process Implications

High Tg FR4 requires modified processing parameters during PCB fabrication and assembly. Lamination cycles may require extended cure times and modified temperature profiles to achieve optimal cross-linking density and mechanical properties.

Drilling operations benefit from the enhanced dimensional stability of High Tg materials, resulting in improved hole quality and reduced drill wander in multilayer constructions. However, the increased hardness may require specialized tooling and adjusted cutting parameters.

Assembly Considerations

Lead-free soldering processes impose thermal stress that approaches or exceeds Standard FR4 capabilities. High Tg FR4 provides essential thermal margin during peak reflow temperatures, reducing warpage and improving joint reliability.

The enhanced thermal performance enables multiple reflow cycles without cumulative degradation, essential for complex assemblies requiring component rework or selective soldering operations.

Partner with Haoyue Electronics for Your FR4 PCB Projects

Haoyue Electronics combines advanced manufacturing capabilities with deep materials expertise to deliver optimal FR4 PCB solutions for your specific applications. Our comprehensive understanding of High Tg and Standard FR4 characteristics enables precise material selection aligned with your performance requirements.

Our specialized capabilities include:

- Advanced multilayer HDI PCB manufacturing with both High Tg and Standard FR4 materials

- Precision thermal management optimization for power electronics applications

- Complete PCB assembly services with lead-free and mixed-technology soldering expertise

- Comprehensive design for manufacturability consultation and material selection guidance

- Quality assurance protocols specifically developed for high-temperature applications

- Rapid prototyping and production scaling for time-critical projects

Whether your project demands the cost-effectiveness of Standard FR4 or the superior thermal performance of High Tg materials, our engineering team provides the technical expertise and manufacturing precision required for success. Contact Haoyue Electronics today to discuss your FR4 PCB requirements and discover how our capabilities can optimize your next project.