The electronics industry continues to push the boundaries of speed and performance, driving demand for circuit boards that can handle higher frequencies with exceptional signal integrity.

High frequency PCBs, typically operating above 1 GHz, have become critical components in modern electronic systems. They enable breakthrough technologies across telecommunications, aerospace, medical, and automotive sectors.

Understanding both high frequency PCB applications and high frequency PCB advantages is essential for engineers and manufacturers developing next-generation electronic products.

High Frequency PCB Applications

1. Telecommunications and 5G Infrastructure

The telecommunications sector represents one of the largest application areas for high frequency PCBs, particularly with the global rollout of 5G networks. These specialized PCBs are essential for transmitting electromagnetic waves in the frequency of GHz with minimal losses, making them indispensable for 5G infrastructure and advanced communication applications. These use cases are among the most critical high frequency PCB applications in today’s telecommunications landscape.

5G base stations require PCBs capable of handling frequencies ranging from 3.5 GHz to 28 GHz and beyond, demanding exceptional signal integrity and minimal loss characteristics. High frequency PCBs enable the high-speed data transmission rates that 5G promises, supporting applications such as:

- Massive MIMO antenna systems for improved network capacity

- Small cell deployments for enhanced coverage density

- Millimeter wave communication equipment

- Advanced beamforming technologies

- High-speed backhaul connections between network nodes

The wireless communication devices market continues expanding beyond traditional smartphones to include IoT sensors, smart city infrastructure, and emerging applications requiring reliable high-frequency signal transmission.

2. Aerospace and Defense Systems

High-frequency PCBs are commonly used in radar systems, military equipment, aerospace applications, and satellite communications. The aerospace and defense sectors demand the highest levels of reliability and performance, making high frequency PCBs indispensable for mission-critical applications. Many aerospace and defense systems represent some of the most demanding high frequency PCB applications, where reliability and precision are non-negotiable.

Key aerospace and defense applications include:

Radar Systems: Modern radar technology operates across multiple frequency bands, with many systems functioning in the X-band (8–12 GHz) and higher frequencies. High frequency PCBs enable precise target detection, tracking, and identification capabilities essential for both civilian air traffic control and military defense systems.

Satellite Communications: Satellite systems require PCBs capable of handling both uplink and downlink frequencies, often in the Ku-band (12–18 GHz) and Ka-band (26.5–40 GHz) ranges. These applications demand exceptional thermal stability and radiation resistance.

Electronic Warfare Systems: Advanced jamming and countermeasure equipment relies on high frequency PCBs to generate and process signals across wide frequency spectrums with minimal distortion.

Navigation Systems: GPS and other global navigation satellite systems utilize high frequency PCBs for precise signal processing and positioning accuracy.

3. Medical and Automotive Electronics

The medical device industry increasingly relies on high frequency PCBs for advanced diagnostic and therapeutic equipment—yet another fast-growing category of high frequency PCB applications where accuracy and signal fidelity are paramount. These specialized circuit boards are used in medical imaging devices and various medical equipment applications.

Medical Imaging Applications:

- MRI systems requiring precise RF signal generation and reception

- Ultrasound equipment for high-resolution diagnostic imaging

- CT scan systems with advanced signal processing capabilities

- Telemedicine devices enabling real-time patient monitoring

Automotive Electronics: The automotive sector’s transition toward electric vehicles and autonomous driving systems creates substantial demand for high frequency PCBs. The automotive industry’s shift towards electric vehicles (EVs) and advanced driver-assistance systems (ADAS) drives the requirement for high-end PCBs that can handle complex functionalities.

Modern vehicles incorporate high frequency PCBs in:

- Advanced radar sensors for collision avoidance and autonomous driving

- Vehicle-to-everything (V2X) communication systems

- High-speed infotainment and connectivity systems

- Electric powertrain control systems requiring precise signal management

High Frequency PCB Advantages

1. Superior Signal Integrity and Performance

Among the key high frequency PCB advantages is their unmatched ability to maintain signal integrity under high-speed and high-frequency conditions. These PCBs are engineered to route signals efficiently while minimizing distortion, making them indispensable in high-performance electronics.

Key Signal Integrity Benefits:

- Reduced Signal Loss: High frequency PCBs utilize materials with low dissipation factors (typically 0.001–0.003 compared to 0.02 for standard FR-4), minimizing energy loss during signal transmission.

- Controlled Impedance: Precise impedance matching prevents signal reflections and ensures efficient power transfer between components.

- Minimized Propagation Delay: Low dielectric constant materials (Dk values of 2.2–3.5) reduce signal propagation delays compared to standard materials.

- Enhanced Bandwidth Capability: Support for higher frequency operations enables greater data throughput and system performance.

2. Electromagnetic Interference Reduction and Noise Control

Another significant advantage of high frequency PCBs lies in their ability to suppress electromagnetic interference (EMI) and minimize signal noise. These designs typically incorporate dedicated ground and power planes that isolate noise-sensitive signals, which is essential in complex electronic environments.

For engineers focused on developing high-reliability and low-noise systems, understanding these high frequency PCB advantages can lead to better design outcomes and improved end-product performance.

EMI Reduction Strategies:

| Technique | Benefit | Implementation |

|---|---|---|

| Ground Plane Design | Reduces radiation and provides return paths | Solid ground planes between signal layers |

| Shielding Integration | Blocks external interference | Dedicated shielding layers and enclosures |

| Controlled Layer Stack-up | Minimizes crosstalk between signals | Strategic placement of power and ground planes |

| Advanced Routing | Reduces loop areas and coupling | Differential pair routing and length matching |

3. Thermal Management and Reliability

One of the critical high frequency PCB advantages is efficient thermal management, which ensures reliable operation under high-frequency conditions. Multi-layered PCBs offer effective heat dissipation through the integration of thermal vias and strategically placed copper layers, enhancing overall system reliability. High frequency operations generate significant heat, making thermal management crucial for long-term reliability and performance.

Thermal Management Advantages:

- Enhanced Heat Dissipation: Strategic copper layer placement and thermal via integration provide efficient heat conduction paths.

- Dimensional Stability: Low coefficient of thermal expansion (CTE) materials prevent board warping and maintain electrical characteristics across temperature ranges.

- Reduced Hot Spots: Uniform heat distribution prevents localized temperature spikes that could damage components.

- Extended Operating Life: Effective thermal management reduces component stress and extends system reliability.

These thermal advantages contribute significantly to the overall high frequency PCB advantages, enabling sustained performance in demanding applications.

Material Performance Characteristics:

| Material Property | Standard FR-4 | High Frequency Materials |

|---|---|---|

| Dielectric Constant (Dk) | 4.0-4.5 | 2.2-3.5 |

| Loss Tangent (Df) | 0.02 | 0.001-0.003 |

| Operating Frequency | Up to 1 GHz | 1 GHz to 100+ GHz |

| Thermal Stability | Limited | Excellent |

Design Considerations and Future Outlook for High Frequency PCBs

The high-frequency and high-speed PCB market is experiencing robust growth, driven by the increasing demand for high-bandwidth applications. With a projected market value exceeding $30 billion by 2033, the adoption of high frequency PCB applications is expanding rapidly across telecommunications, aerospace, medical, automotive, and other advanced industries.

Critical Design Factors for High Frequency PCBs:

- Material Selection: Choosing appropriate substrates with optimal electrical and thermal properties to support high frequency signal integrity and thermal management.

- Layer Stack-up Planning: Balancing signal integrity requirements with manufacturing constraints to achieve controlled impedance and minimal crosstalk.

- Via Management: Minimizing parasitic capacitance and inductance through strategic via placement and advanced via designs, critical for high frequency performance.

- Trace Geometry: Optimizing trace width, spacing, and routing paths to maintain controlled impedance and reduce signal loss.

Looking ahead, the future of high frequency PCB technology points toward even higher operating frequencies, improved material properties, and enhanced integration capabilities. Emerging applications such as 6G communications, quantum computing, advanced radar, and sensing systems will continue driving innovation in high frequency PCB design and manufacturing, pushing the limits of what modern electronics can achieve.

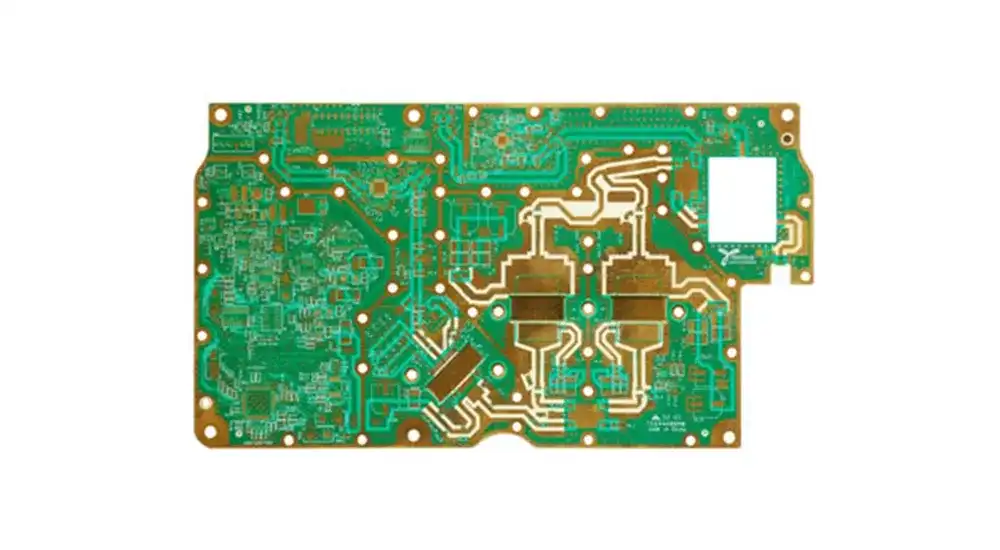

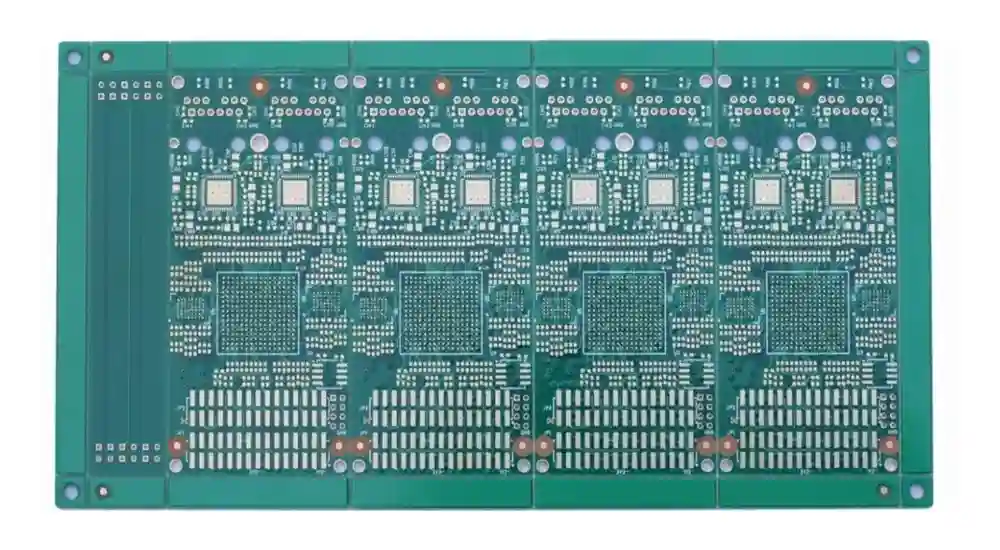

Partner with Haoyue Electronics for Advanced PCB Solutions

As the demand for high frequency PCB applications continues expanding across telecommunications, aerospace, medical, and automotive sectors, selecting the right manufacturing partner becomes crucial for project success. Haoyue Electronics specializes in precision manufacturing and assembly of high frequency PCBs, combining advanced materials expertise with state-of-the-art production capabilities.

Our engineering team understands the unique challenges of high frequency PCB design, from material selection and impedance control to thermal management and signal integrity optimization. Whether you’re developing 5G infrastructure equipment, aerospace radar systems, or next-generation medical devices, we provide comprehensive PCB manufacturing and assembly services tailored to your specific requirements.

Contact Haoyue Electronics today to discuss your high frequency PCB project and discover how our expertise in advanced circuit board technologies can accelerate your product development while ensuring superior performance, reliability, and cost-effectiveness.