FR4 is a thermoset glass fabric reinforced epoxy resin composite, representing the most widely used substrate in PCB manufacturing. Rogers is a family of PTFE composite substrates reinforced with ceramic filler particles, specifically engineered for demanding high-frequency applications. This comprehensive comparison examines the critical properties that determine which material suits specific design requirements.

Material Properties and Dielectric Performance

The fundamental difference between FR4 and Rogers PCB materials lies in their dielectric characteristics, which directly influence high-frequency performance. FR4 suffers from performance limitations at higher frequencies due to dielectric losses, making it unsuitable for many RF applications.

FR4 vs Rogers Dielectric Constant

The dielectric constant (Dk) of Rogers materials ranges from 2.9 to 10.2 depending on the specific material, while FR4 has a typical dielectric constant between 4.3 to 4.7. This broader range in Rogers materials provides engineers with greater flexibility in impedance design. Rogers material with a dielectric constant value of 6.5-11 is preferred for high thermal applications where impedance stability is crucial.

The stability of the dielectric constant across frequency ranges represents a critical advantage for Rogers materials. Rogers maintains stable dielectric properties up to mmWave frequencies, while FR4 is usable only to a few GHz before losses become problematic. This stability ensures consistent impedance control in high-frequency circuits.

Loss Tangent Performance

Signal integrity in high-frequency applications depends heavily on the material’s loss tangent (Df). The loss tangent of Rogers materials ranges from approximately 0.0009 to 0.002 at 10 GHz, compared to FR4’s loss tangent of approximately 0.02 at 1 MHz. The dissipation factor of Rogers material PCB is 0.004%, while the dissipation factor of FR4 material PCB is 0.02%.

This significant difference in loss tangent translates to substantially reduced signal attenuation in Rogers-based designs. Transmission loss and insertion loss of Rogers laminates are almost 50-80% lower than traditional FR4 material, making Rogers the preferred choice for applications where signal integrity cannot be compromised.

Thermal Management and Temperature Stability

FR4 vs Rogers Thermal Conductivity

Thermal management becomes increasingly critical in high-speed and high-power applications. Rogers materials exhibit thermal conductivity greater than 0.5 W/mK, while FR4 provides approximately 0.25 W/mK. This enhanced thermal conductivity enables Rogers PCBs to dissipate heat more effectively, preventing thermal-induced performance degradation.

Glass Transition Temperature (Tg)

The glass transition temperature represents another crucial thermal parameter. The Tg or glass transition temperature for Rogers material is substantially higher than that of FR4 PCBs. This higher Tg provides better dimensional stability during thermal cycling and enables reliable operation in elevated temperature environments.

Rogers materials also exhibit very low CTE or Coefficient of Thermal Expansion, allowing PCBs to maintain their dimensions despite wide temperature fluctuations. This thermal stability proves essential for maintaining signal integrity in temperature-varying environments.

Manufacturing Considerations and Processing Challenges

The fabrication process represents a significant factor when choosing between FR4 and Rogers materials. RO4000 series material does not need any special treatment for the through-hole process and does not need to add any extra technology process, making it more compatible with standard PCB manufacturing equipment.

However, Rogers materials generally require more careful handling during fabrication. For unreinforced Rogers materials, they are more difficult to work with in thinner layers, which could increase fabrication costs and create a danger of greater misregistration during PCB fabrication.

The processing considerations extend to drilling, plating, and etching operations. Rogers materials, particularly PTFE-based variants, require specialized handling techniques to achieve reliable via formation and copper adhesion. This processing complexity can impact manufacturing yields and production timelines.

FR4 PCB vs Rogers PCB Cost Comparison

Cost analysis reveals a substantial difference between these materials. Rogers materials cost 5-10x more compared to FR4 on a per area basis due to their exotic material compositions. This cost differential makes material selection a critical economic decision.

When to Choose FR4 Over Rogers PCB

For cost-driven consumer PCBs where performance is not critical, FR4 remains a popular choice. FR4 provides adequate performance for applications operating below 1 GHz, making it suitable for general-purpose electronics, consumer devices, and industrial control systems.

FR4 PCB applications include standard digital circuits, power management systems, and low-frequency analog designs where the higher loss tangent does not significantly impact performance. The material’s proven reliability and extensive manufacturing infrastructure support its continued use in cost-sensitive applications.

Rogers vs FR4 PCB Signal Loss Performance

Rogers offers tight control of dielectric constant for controlled impedance traces and low loss for clean signal transmission, while FR4 has less consistent dielectrics and suffers high frequency attenuation. This performance advantage becomes crucial in applications where signal integrity directly impacts system functionality.

The superior signal integrity of Rogers materials enables higher data rates, longer trace lengths, and more complex routing in high-speed designs. These advantages justify the additional cost in performance-critical applications.

Application-Specific Material Selection

FR4 vs Rogers PCB in RF and Microwave Applications

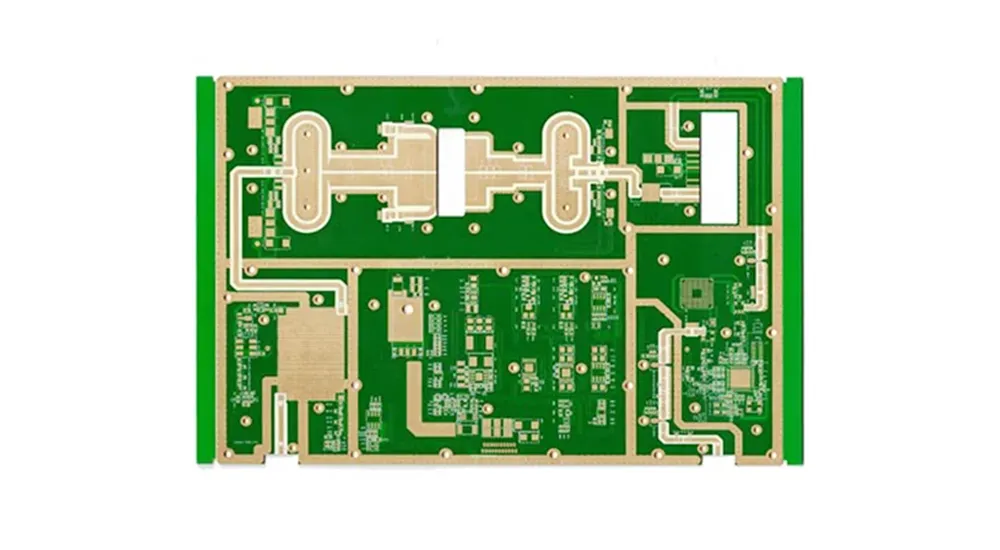

When the frequency is over 500 MHz, PCB designers are inclined to choose Rogers material, especially for RF circuit board or microwave circuit board applications. The stable dielectric properties and low loss characteristics make Rogers materials essential for maintaining signal integrity in these demanding applications.

For radar systems, satellite communications, medical imaging, etc. operating well into the mmWave region, FR4 losses would be prohibitive, requiring Rogers or even ceramic substrates. These applications demand the superior electrical performance that only specialized materials can provide.

Which is Better FR4 or Rogers PCB

The determination of which material is better depends entirely on application requirements. Rogers PCB materials are typically suitable for RF applications and high-reliability systems, such as in military applications, while FR4 serves admirably in cost-sensitive, lower-frequency applications.

The telecommunications sector uses Rogers materials extensively for producing antennas, base station equipment, and satellite communication systems. The aerospace and defense industries rely on Rogers materials for their superior performance under extreme environmental conditions.

FR4 vs Rogers for High-Frequency PCB Design

High-frequency design considerations favor Rogers materials for several reasons. Rogers maintains stable dielectric properties up to mmWave frequencies and offers precise dielectric properties with close matching to copper. These characteristics enable predictable performance in demanding high-frequency applications.

The choice between materials often involves hybrid approaches where Rogers materials are used for critical RF sections while FR4 handles lower-frequency digital and power management functions. Rogers material can be used together with FR4 material to reduce the overall cost while meeting high-frequency PCB requirements.

Why Choose Haoyue Electronics for Your FR4 PCB Projects

Haoyue Electronics combines advanced manufacturing capabilities with deep expertise in both FR4 and Rogers PCB technologies. Our comprehensive approach to PCB manufacturing and assembly ensures optimal material selection and processing for your specific requirements.

Our capabilities include:

- Advanced impedance control with tolerances below ±5% for high-frequency applications

- Hybrid PCB fabrication combining FR4 and Rogers materials in single stackups

- Complete thermal management solutions for high-power and high-speed designs

- Full-service PCB assembly with expertise in both standard FR4 and specialized Rogers applications

- Comprehensive testing and validation services ensuring signal integrity compliance

- Cost optimization strategies balancing performance requirements with budget constraints

Our engineering team provides material selection guidance to help you choose between FR4 and Rogers based on your specific frequency, thermal, and cost requirements. Whether your project demands the cost-effectiveness of FR4 for standard applications or the superior performance of Rogers for high-frequency designs, Haoyue Electronics delivers the expertise and manufacturing excellence your project requires.

Contact our engineering team to discuss how we can optimize your PCB material selection and manufacturing approach for maximum performance and value.