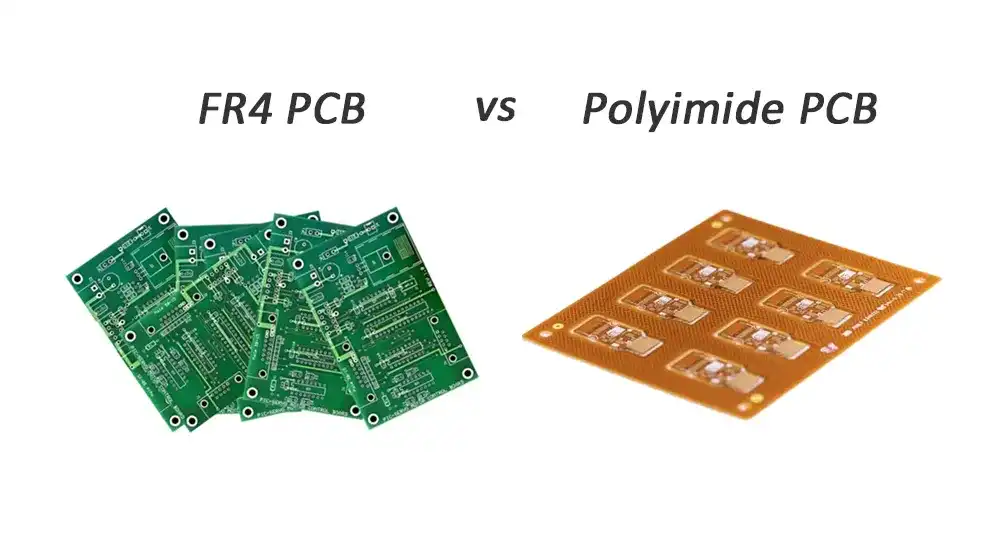

Material Composition and Structural Characteristics

FR4 PCB Material Properties

FR4 PCB material consists of woven fiberglass cloth impregnated with flame-retardant epoxy resin, creating a composite substrate with predictable electrical and mechanical properties. The designation “FR4” indicates compliance with flame retardancy standards under UL94 V-0 rating, ensuring consistent performance across various manufacturing processes.

The structural composition of FR4 provides excellent dimensional stability with a glass transition temperature of approximately 135°C. This characteristic makes FR4 PCB material particularly suitable for applications requiring rigid mechanical support and consistent dielectric properties across moderate temperature ranges.

Polyimide PCB Material Foundation

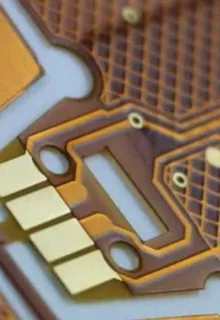

Polyimide PCB material derives from imide monomer polymerization, resulting in a substrate with exceptional thermal stability and mechanical flexibility. The polymer chain structure contains aromatic rings connected by imide linkages, providing inherent resistance to thermal degradation and chemical attack.

This molecular architecture enables Polyimide PCBs to maintain structural integrity across temperature ranges from -220°C to 300°C, significantly exceeding the operational limits of conventional FR4 PCB material. The flexibility characteristics of Polyimide PCB material allow for dynamic bending applications while preserving electrical continuity.

Thermal Performance Analysis

High Temperature PCB Materials Comparison

The thermal performance differences between FR4 and Polyimide PCB materials become pronounced in elevated temperature environments. FR4 PCB material maintains acceptable performance within -50°C to 110°C operational ranges, with thermal conductivity values typically ranging from 0.3 to 0.4 W/mK.

Polyimide PCB material demonstrates superior thermal stability, withstanding continuous operation at temperatures exceeding 200°C without significant degradation. The glass transition temperature of high-performance Polyimide formulations reaches 195-220°C, providing substantial safety margins for demanding thermal applications.

Thermal Expansion Characteristics

Coefficient of thermal expansion (CTE) represents a critical factor when evaluating FR4 vs Polyimide thermal properties. FR4 PCB material exhibits anisotropic expansion characteristics, with different CTE values in X-Y plane versus Z-axis directions. This behavior requires careful consideration during thermal cycling applications.

Polyimide PCB material offers more controlled thermal expansion properties, with relatively uniform CTE values across all directions. This characteristic proves particularly beneficial in applications experiencing rapid temperature transitions or extended thermal cycling requirements.

Mechanical Properties and Flexibility Comparison

Flexible PCB Materials Assessment

The fundamental distinction in flexible PCB materials comparison centers on mechanical compliance and bend radius capabilities. FR4 PCB material, while offering excellent rigidity and mechanical strength, exhibits limited flexibility characteristics suitable only for minimal bending applications.

Polyimide PCB material excels in flexible PCB vs rigid PCB applications, supporting dynamic flexing with bend radii as small as 1-2 times the substrate thickness. This capability enables integration into compact electronic assemblies where space constraints demand conformable circuit solutions.

Tensile Strength and Durability

Mechanical strength characteristics differ significantly between these substrate materials. FR4 PCB material provides tensile strength values around 415 MPa, offering robust mechanical support for component mounting and handling operations.

Polyimide PCB material achieves tensile strength values of approximately 231 MPa while maintaining superior elongation properties. This combination enables Polyimide PCBs to absorb mechanical stress through controlled deformation rather than brittle failure modes typical of FR4 substrates.

Electrical Performance Characteristics

Dielectric Properties Analysis

FR4 PCB material properties include dielectric constant values ranging from 4.2 to 4.8 at 1 GHz, with dissipation factor typically below 0.02. These characteristics provide stable electrical performance for general-purpose applications across moderate frequency ranges.

Polyimide PCB material exhibits dielectric constant values between 3.4 and 3.6, offering reduced signal propagation delays and improved high-frequency performance. The lower dielectric constant contributes to enhanced signal integrity in high-speed digital applications.

Signal Integrity Considerations

The difference between FR4 and Polyimide PCB materials extends to signal transmission characteristics. FR4 substrates demonstrate adequate performance for frequencies below 1 GHz, with signal integrity maintained through proper design practices.

Polyimide PCB advantages include superior performance at higher frequencies due to lower dielectric losses and more stable electrical properties across temperature variations. This characteristic proves essential for RF applications and high-speed digital circuits operating above conventional frequency ranges.

Application-Specific Use Cases

When to Choose Polyimide PCB Over FR4 PCB

Polyimide PCB benefits in high temperature environments make this material the preferred choice for aerospace, automotive engine management, and industrial process control applications. The enhanced thermal stability enables reliable operation in environments where FR4 PCB limitations would result in premature failure.

Applications of Polyimide PCB vs FR4 PCB extend beyond thermal considerations to include space-constrained designs requiring flexible interconnects. Consumer electronics, medical devices, and wearable technology benefit from the mechanical compliance that Polyimide substrates provide.

Optimal FR4 PCB Applications

FR4 PCB material remains the optimal choice for cost-sensitive applications requiring rigid mechanical support without extreme environmental demands. General computing, telecommunications infrastructure, and consumer appliances typically benefit from the proven reliability and economic advantages of FR4 substrates.

The advantages of Polyimide PCBs compared to FR4 must be weighed against the increased material costs and specialized manufacturing requirements. For applications operating within conventional temperature ranges and requiring minimal flexibility, FR4 PCB material provides excellent value proposition.

Cost Analysis and Manufacturing Considerations

Economic Impact Assessment

Cost comparison between FR4 and Polyimide PCBs reveals significant differences in material expenses, with Polyimide substrates typically commanding premium pricing of 300-500% compared to equivalent FR4 options. This cost differential reflects the specialized manufacturing processes and raw material expenses associated with high-performance polymer production.

However, the total cost of ownership analysis must consider the enhanced reliability and extended operational life that Polyimide PCB material provides in demanding applications. Reduced failure rates and maintenance requirements often justify the initial material cost premium in critical system applications.

Manufacturing Process Variations

FR4 PCB manufacturing utilizes established processes with widespread industry capability and competitive pricing structures. Standard lamination, drilling, and plating operations apply conventional parameters suitable for most electronic manufacturing services providers.

Polyimide PCB manufacturing requires specialized equipment and process control to accommodate the unique characteristics of flexible substrates. The thermal and mechanical properties of Polyimide material demand modified handling procedures and adapted manufacturing parameters.

Haoyue Electronics PCB Manufacturing Capabilities

Selecting the appropriate substrate material represents only the initial step in successful PCB implementation. Professional manufacturing and assembly capabilities ensure that design intent translates into reliable electronic products. Haoyue Electronics combines extensive experience in both FR4 PCB material properties and Polyimide PCB material processing to deliver optimal solutions across diverse application requirements.

Our comprehensive PCB manufacturing and assembly capabilities include:

- Advanced multilayer FR4 PCB fabrication with controlled impedance and high-density interconnect technologies

- Specialized Polyimide PCB processing for flexible and rigid-flex applications requiring superior thermal performance

- Precision assembly services supporting both conventional FR4 and high-temperature Polyimide substrates

- Quality assurance protocols ensuring consistent performance across standard and specialized PCB materials

- Engineering support services for optimal material selection and design optimization

The successful implementation of either FR4 or Polyimide PCB solutions requires manufacturing partners with proven expertise in substrate-specific processing requirements. Contact Haoyue Electronics to discuss your specific application requirements and discover how our advanced manufacturing capabilities can optimize your PCB performance while maintaining cost-effective production solutions.