With the growing complexity of electronic designs, understanding the properties and applications of various double layer PCB materials becomes essential for engineers and designers. This comprehensive guide explores the most critical aspects of double layer printed circuit board material selection, equipping professionals with the technical insights needed to make optimal design decisions.

Understanding Double Layer PCB Construction and Material Requirements

Core Material Functions in Double Layer Boards

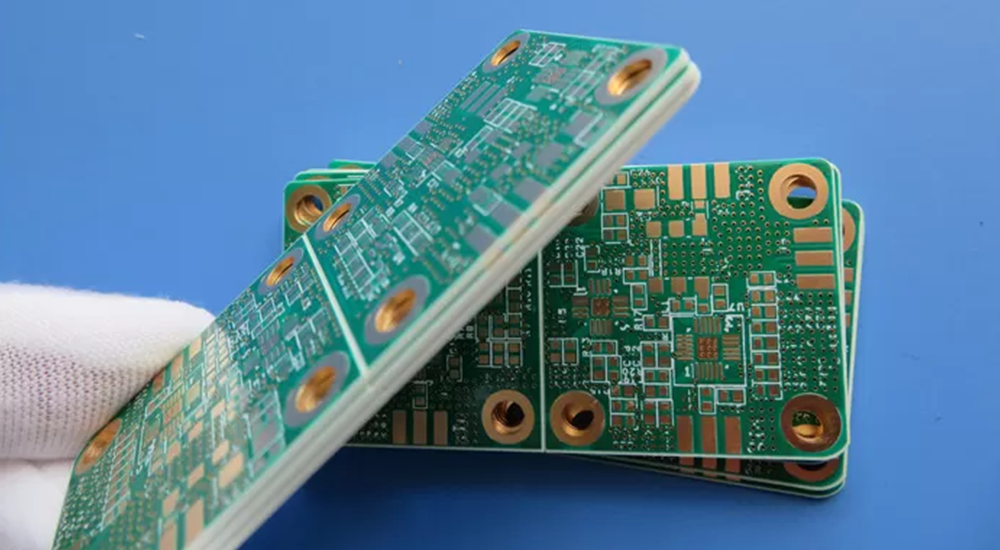

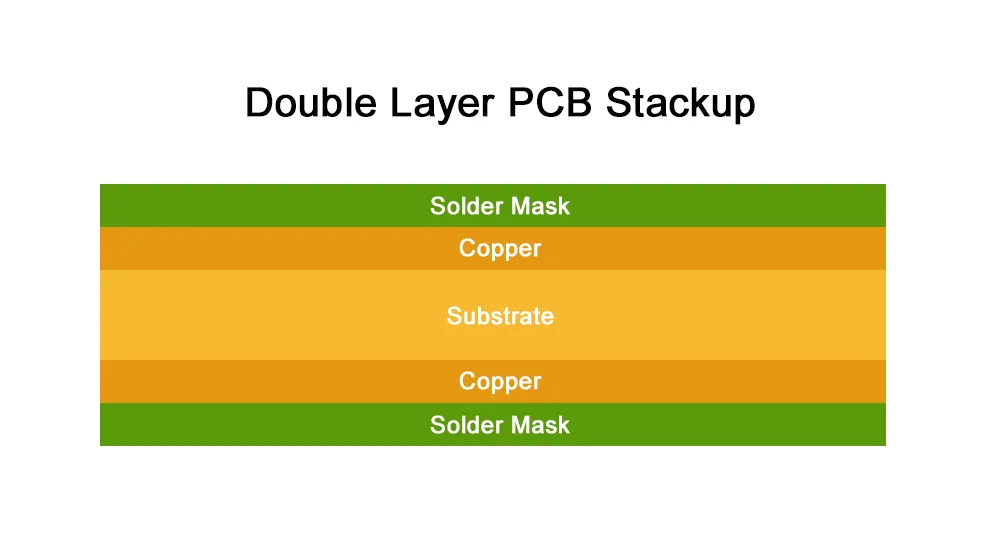

Double layer PCBs are composed of two conductive copper layers separated by a dielectric substrate, forming the essential structure of most electronic circuits. The substrate serves several critical roles: it provides mechanical stability, ensures electrical insulation between layers, and facilitates thermal management. Selecting the right double layer PCB materials involves careful evaluation of electrical, thermal, and mechanical properties to meet the demands of specific applications.

Critical Performance Parameters

The overall performance of double layer PCBs is closely tied to the material properties used in their construction. Key parameters include the dielectric constant (Dk), which affects signal propagation and impedance control, and the dissipation factor (Df), which influences signal loss and power efficiency. Thermal conductivity is essential for effective heat dissipation, while the glass transition temperature (Tg) defines the material’s ability to withstand thermal stress. Understanding these characteristics helps engineers select double layer PCB materials that enhance circuit reliability and performance.

Substrate Materials for Double Layer PCBs

FR-4: Industry Standard and Variants

FR-4 is the most widely used substrate material for double layer PCB applications, offering a reliable balance of electrical performance, mechanical strength, and cost efficiency. Standard FR-4 features a dielectric constant of approximately 4.5 at 1 MHz and a thermal conductivity of around 0.3 W/m·K. Its composite structure, consisting of woven fiberglass and epoxy resin, delivers excellent dimensional stability and structural integrity for general-purpose electronics.

For more demanding environments, High-Tg FR-4 materials are available with enhanced thermal characteristics. These variants typically offer glass transition temperatures between 150°C and 170°C, compared to the 130°C of standard FR-4. This improvement makes them well-suited for double layer PCB materials used in automotive, industrial, and high-power electronic systems where elevated operating temperatures are common.

High-Performance Alternatives

| Material Type | Dielectric Constant | Thermal Conductivity | Operating Temperature | Primary Applications |

|---|---|---|---|---|

| Standard FR-4 | 4.5 @ 1MHz | 0.3 W/m·K | -40°C to +130°C | Consumer electronics, IoT devices |

| High-Tg FR-4 | 4.2 @ 1MHz | 0.4 W/m·K | -55°C to +150°C | Automotive, industrial controls |

| Polyimide | 3.5 @ 1MHz | 0.2 W/m·K | -200°C to +260°C | Flexible circuits, aerospace |

| PTFE-based | 2.1 - 3.0 @ 1MHz | 0.25 W/m·K | -200°C to +200°C | RF/microwave applications |

Specialty Materials for Demanding Applications

In advanced electronic designs, standard FR-4 materials may not meet the stringent performance requirements. In such cases, specialized substrate options are used to enhance the reliability and functionality of double layer PCB materials. Polyimide substrates offer excellent thermal stability and flexibility, making them ideal for applications involving dynamic bending, tight bend radii, or exposure to extreme temperatures. They are commonly used in aerospace systems, medical electronics, and flexible circuit assemblies.

For high-frequency applications, PTFE-based materials deliver superior performance thanks to their low dielectric loss and stable electrical properties across wide frequency spectrums. These materials are particularly suitable for RF and microwave circuits where signal integrity is critical.

Ceramic substrates, such as aluminum nitride (AlN), are considered premium double layer PCB materials for high-power or high-heat environments. With thermal conductivity values exceeding 170 W/m·K, ceramic materials support effective heat dissipation and maintain dimensional stability, making them essential for LED modules, power amplifiers, and automotive power control systems.

Dielectric Properties and Signal Integrity

Dielectric Constant Considerations

The dielectric constant (Dk) plays a critical role in determining signal propagation behavior in double layer PCBs. Materials with lower dielectric constants enable faster signal transmission and reduced propagation delay, which are essential for high-speed digital applications. The signal velocity in PCB traces is approximately proportional to 1 divided by the square root of the effective dielectric constant (εr), making Dk a key factor in timing and impedance control.

For circuits operating below 1 GHz, standard FR-4 substrates offer sufficient dielectric performance. However, for high-speed digital signals, RF systems, and microwave applications, it becomes necessary to select double layer PCB materials with tightly controlled dielectric properties and minimal variation over frequency to maintain signal integrity.

Loss Tangent and High-Frequency Performance

Loss tangent (tan δ), also known as dissipation factor, quantifies how much signal energy is lost as heat during transmission through the substrate. In double layer PCB materials, this parameter directly impacts signal attenuation and power efficiency. Standard FR-4 has a typical loss tangent of about 0.02, which is acceptable for moderate-frequency circuits but can introduce significant losses in high-speed designs.

Advanced PCB materials designed for high-frequency applications often feature loss tangent values below 0.005. These low-loss substrates help preserve signal strength, reduce jitter, and improve overall system performance, especially as data rates reach multi-gigahertz levels. Choosing low-loss materials is crucial in applications such as 5G modules, radar systems, and high-speed digital communication boards.

Material Selection Criteria for Optimal Performance

Electrical Requirements Assessment

Effective material selection for double layer PCBs begins with a thorough evaluation of electrical performance requirements. Key factors include operating frequency range, signal rise time, and impedance targets. For high-speed digital circuits with edge rates faster than 1 nanosecond, low-Dk double layer PCB materials are essential to preserve signal integrity and reduce electromagnetic interference (EMI).

Power delivery considerations also play a vital role. High-current traces require materials with sufficient thermal conductivity and compatible copper thickness. In such cases, the use of enhanced thermal substrates or integrated thermal vias can improve reliability and performance in power-dense designs.

Thermal Management Considerations

Thermal performance is a critical factor in the selection of double layer PCB materials, especially in power electronics and LED systems. Substrate thermal conductivity directly influences junction temperatures and overall component lifespan. Standard FR-4, with its thermal conductivity of approximately 0.3 W/m·K, may be insufficient for high-power applications, prompting the use of thermally conductive materials or supplemental cooling techniques.

Another important consideration is the coefficient of thermal expansion (CTE). Matching the CTE of the substrate with that of the components helps reduce mechanical stress caused by thermal cycling, minimizing solder joint fatigue and improving long-term reliability.

Environmental and Mechanical Factors

Environmental conditions must also be factored into material selection. Properties such as moisture absorption, chemical resistance, and UV stability influence long-term durability. For outdoor or marine applications, double layer PCB materials with enhanced moisture resistance and environmental sealing are highly recommended.

Mechanical stresses vary widely across end-use environments. Applications in aerospace, defense, or automotive sectors often demand materials with superior vibration resistance, impact strength, and flexural rigidity. These industries typically follow strict qualification and mechanical testing standards that directly guide substrate material choices.

Advanced Material Characterization and Testing

Material Property Verification

Comprehensive material characterization ensures specified properties align with application requirements. Dielectric property measurements across frequency ranges verify electrical performance expectations. Thermal analysis including differential scanning calorimetry (DSC) and thermogravimetric analysis (TGA) confirms thermal stability and processing compatibility.

Quality Control Standards

Industry standards such as IPC-4101 provide specification frameworks for PCB substrate materials. These standards establish test methods and acceptance criteria for electrical, thermal, and mechanical properties. Compliance with relevant standards ensures material consistency and manufacturing reliability.

Cost-Performance Optimization Strategies

Effective material selection balances performance requirements with cost constraints through systematic trade-off analysis. Standard FR-4 materials often provide optimal cost-performance ratios for applications not requiring specialized properties. Design optimization techniques, including proper layer stackup and thermal management strategies, can extend standard material capabilities while controlling costs.

Performance modeling and simulation tools enable evaluation of material alternatives before prototype fabrication, reducing development costs and time-to-market. Early material selection decisions significantly impact overall project economics and technical success.

At Haoyue Electronics, we understand that optimal double layer PCB materials selection directly impacts your product’s performance and reliability. Our experienced engineering team provides comprehensive material consultation services, helping you navigate the complex landscape of substrate options to achieve your specific design goals.

From prototype development to high-volume production, we deliver precision-manufactured PCBs using industry-leading materials and processes. Contact our technical specialists today to discuss your double layer PCB requirements and discover how our material expertise can enhance your next electronic design project.

FAQ

1. What are the best materials for high-frequency double layer PCBs?

PTFE-based and low-Dk ceramic materials offer minimal signal loss, making them ideal for high-speed and RF applications.

2. Can FR-4 be used in automotive applications?

Yes, but High-Tg FR-4 is preferred for better thermal stability in automotive control systems.

3. How does material choice impact signal integrity in double layer PCBs?

Dielectric constant, loss tangent, and substrate uniformity all affect impedance and signal loss, especially in fast digital circuits.