Introduction

High speed PCB design presents two critical challenges that can significantly impact product performance: crosstalk and electromagnetic interference (EMI). These phenomena become increasingly problematic as signal frequencies rise and trace densities increase in modern electronic systems.

Crosstalk PCB design issues can degrade signal integrity, while EMI in high speed PCB applications creates compliance challenges for EMC certification standards such as FCC and CE requirements. Understanding the root causes and implementing effective solutions during the design phase is essential for achieving reliable, compliant electronic products.

Fundamental Concepts

What is Crosstalk?

Crosstalk refers to unwanted electromagnetic coupling between adjacent signal traces that causes interference. This phenomenon manifests in two primary forms: near-end crosstalk (NEXT), where interference appears at the driving end of the victim trace, and far-end crosstalk (FEXT), occurring at the receiving end. The coupling mechanism involves both capacitive and inductive interactions between parallel conductors, with the severity increasing proportionally to signal frequency and inversely to trace separation.

What is EMI in High Speed PCB?

EMI in high speed PCB applications encompasses electromagnetic radiation generated by fast-switching digital signals that can interfere with other electronic systems or violate regulatory emission limits. These emissions result from current loops, impedance discontinuities, and resonant structures within the PCB. The challenge intensifies with higher frequencies, where wavelengths become comparable to PCB dimensions, creating efficient radiating antennas.

Crosstalk Generation Mechanisms

Several design factors contribute to crosstalk susceptibility in high speed circuits. Insufficient trace spacing represents the most common cause, as electromagnetic coupling strength follows an inverse relationship with distance. Extended parallel trace runs exacerbate the problem by increasing coupling length, while inadequate layer stackup design creates discontinuous return paths that force currents through unintended loops.

Differential pair routing requires particular attention, as mismatched trace spacing and length can convert common-mode signals into differential-mode noise. Poor via placement near sensitive signals can introduce additional coupling paths through mutual inductance between via structures.

EMI Root Causes in High Speed PCB Design

The primary sources of EMI in high speed PCB applications stem from fundamental electromagnetic principles. Fast signal transitions generate broadband spectral content that extends well beyond the fundamental frequency, creating potential emission sources across wide frequency ranges. Power and ground plane discontinuities force return currents through circuitous paths, forming large current loops that act as efficient radiating antennas.

Structural irregularities such as vias, connectors, and component placements create impedance mismatches that reflect energy and generate standing waves. These resonances can amplify emissions at specific frequencies. Additionally, inadequate decoupling and filtering allow high-frequency noise to propagate through power distribution networks, creating multiple emission sources throughout the system.

Advanced Crosstalk Mitigation Strategies

Geometric and Physical Design Approaches

Effective crosstalk PCB design begins with strategic trace spacing optimization. The 3W rule, requiring trace separation of three times the trace width, provides a baseline for significant coupling reduction. However, critical applications may demand spacing up to 5W or greater, particularly for high-frequency digital signals exceeding 1 GHz.

Differential pair implementation requires precise geometric control to maintain consistent spacing and minimize skew. The target impedance must be maintained throughout the entire signal path, including layer transitions and via structures. Controlled impedance in high speed PCB layout becomes crucial for maintaining signal integrity while minimizing crosstalk susceptibility.

Advanced Isolation Techniques

Guard trace implementation provides active isolation between sensitive signal pairs. These grounded conductors create electromagnetic barriers that redirect coupling currents to ground rather than adjacent victim traces. Proper guard trace design requires connection to solid ground planes at regular intervals, typically every quarter wavelength at the highest frequency of concern.

Layer assignment strategies significantly impact crosstalk performance. Orthogonal routing between adjacent layers minimizes broadside coupling, while maintaining close proximity to reference planes reduces loop inductance. The optimal stackup places high-speed signals between solid planes, creating controlled impedance environments with minimal electromagnetic radiation.

Comprehensive EMI Reduction Methodologies

Ground plane integrity forms the foundation of effective EMI control in high speed PCB applications. Continuous reference planes provide low-impedance return paths that minimize current loop areas and reduce electromagnetic radiation. Strategic via placement ensures proper layer-to-layer connections without creating resonant cavities or impedance discontinuities.

Power distribution network design requires careful attention to decoupling and filtering strategies. Multiple capacitor values create broadband noise suppression, with placement proximity to switching devices minimizing loop inductance. Ferrite beads and common-mode chokes provide additional filtering for differential and common-mode noise respectively.

Shielding effectiveness depends on proper implementation techniques rather than simply adding metallic enclosures. Gaskets, conductive coatings, and strategic grounding create continuous electromagnetic barriers. However, apertures for connectors and cooling must be carefully designed to maintain shielding integrity across the required frequency spectrum.

Signal Integrity Optimization for Combined Crosstalk and EMI Control

Modern high speed PCB design requires simultaneous consideration of crosstalk and EMI, as these phenomena often interact synergistically. Crosstalk-induced noise can modulate emissions, creating unexpected spectral components that complicate EMC compliance. Conversely, EMI reduction techniques such as spread-spectrum clocking can inadvertently increase crosstalk by broadening signal spectra.

Rise time control represents a powerful technique for addressing both challenges simultaneously. Slower edge rates reduce high-frequency spectral content, diminishing both crosstalk coupling and EMI generation. However, this approach requires careful balance against timing requirements and signal integrity constraints. Driver strength optimization and series termination techniques provide practical implementation methods.

The fundamental differences between high speed PCB vs standard PCB design approaches become critical when addressing these combined challenges. Standard PCB design rules often prove inadequate for frequencies above 100 MHz, requiring specialized modeling and verification techniques.

Haoyue Electronics: Advanced High Speed PCB Manufacturing Solutions

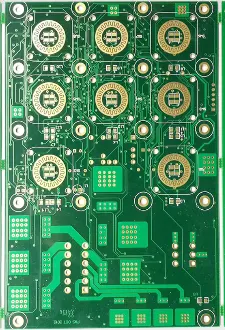

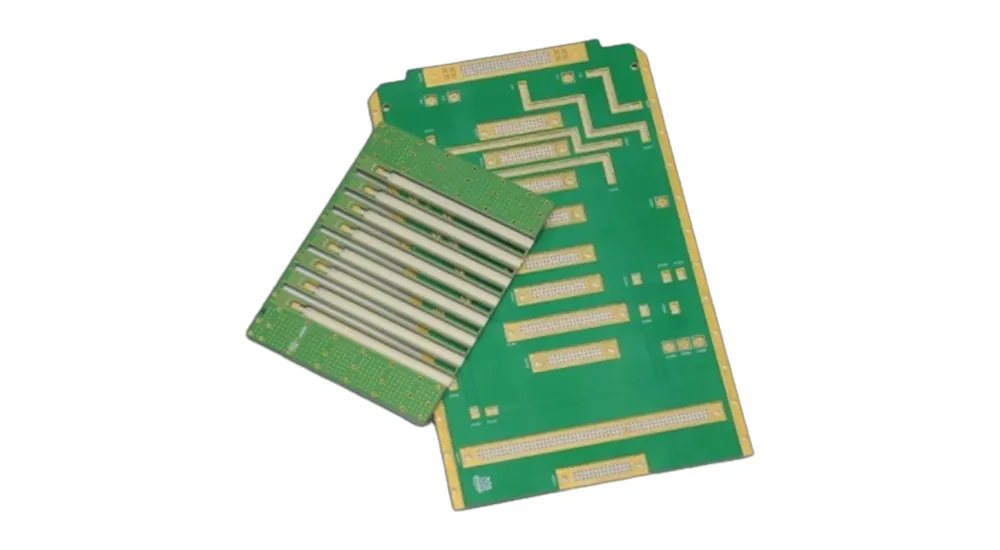

At Haoyue Electronics, we understand the critical importance of precision manufacturing in addressing crosstalk and EMI challenges. Our advanced PCB fabrication and assembly capabilities specifically target high speed applications where signal integrity and electromagnetic compatibility are paramount.

Our specialized high speed PCB manufacturing services include:

- Controlled impedance fabrication with ±5% tolerance for critical signal integrity applications

- Advanced stackup design supporting up to 32 layers with optimized reference plane placement

- Precision via technology including microvias and buried vias for dense, high-frequency designs

- Low-loss dielectric materials including Rogers, Isola, and other specialized high-frequency substrates

- Comprehensive testing and validation using TDR, VNA, and EMC pre-compliance verification

Our experienced engineering team collaborates with customers during the design phase to optimize layouts for both crosstalk reduction and EMI compliance. Through early engagement, we help identify potential issues before fabrication, reducing development time and ensuring first-pass success.

Contact Haoyue Electronics today to discuss your high speed PCB challenges and discover how our manufacturing expertise can enhance your product performance and reliability.

Conclusion

Crosstalk and EMI represent interconnected challenges in high speed PCB design that require systematic, physics-based approaches for effective resolution. Success depends on understanding the fundamental electromagnetic principles governing these phenomena and implementing comprehensive design strategies addressing layout, materials, and manufacturing considerations. Through careful attention to trace geometry, layer stackup optimization, power integrity, and shielding techniques, designers can achieve both signal integrity objectives and EMC compliance requirements. The investment in proper design methodology during early development phases prevents costly redesign cycles and ensures reliable product performance across the intended operating environment.

Frequently Asked Questions

What is the minimum trace spacing required to prevent crosstalk in high speed PCB design?

The minimum trace spacing depends on several factors including signal frequency, trace geometry, and acceptable crosstalk levels. For general high speed digital applications, the 3W rule (spacing equals three times trace width) provides approximately -40dB crosstalk reduction. Critical applications may require 5W spacing or greater, particularly for frequencies exceeding 1 GHz where electromagnetic coupling becomes more significant.

How does EMI in high speed PCB differ from standard PCB emission sources?

EMI in high speed PCB applications exhibits broader spectral content due to faster signal transition times, creating harmonics that extend well beyond the fundamental frequency. High speed designs also generate emissions through impedance discontinuities, resonant structures, and power distribution network noise that become significant radiators at frequencies above 100 MHz. Standard PCB designs typically produce narrowband emissions primarily at clock frequencies and their harmonics.

What PCB layout optimization techniques most effectively reduce both crosstalk and EMI simultaneously?

The most effective techniques include maintaining continuous reference planes for low-impedance return paths, implementing proper layer stackup with signal layers adjacent to ground planes, controlling signal rise times through driver optimization, and ensuring consistent impedance throughout signal paths. Strategic via placement and differential pair routing with matched lengths also provide significant improvements for both crosstalk prevention and EMI reduction.

How do I determine if my high speed PCB design requires specialized EMI reduction techniques?

Specialized EMI reduction techniques become necessary when operating frequencies exceed 100 MHz, when the PCB dimensions approach one-tenth wavelength of the highest frequency component, or when the application requires compliance with stringent EMC standards. Additionally, designs with fast rise times (less than 1 ns), high current switching, or sensitive analog circuits typically benefit from advanced EMI control measures including specialized shielding and filtering techniques.

What role does controlled impedance play in crosstalk PCB design for high frequency applications?

Controlled impedance maintains signal integrity by preventing reflections and standing waves that can increase electromagnetic radiation and crosstalk susceptibility. Impedance mismatches create reflection points that generate additional noise sources and can cause signals to radiate more efficiently. Proper impedance control also ensures differential pairs maintain their common-mode rejection capabilities, reducing both crosstalk sensitivity and EMI generation from mode conversion effects.