Introduction

In today’s rapidly evolving electronics landscape, High Speed PCB applications spanning 5G communications, data centers, AI servers, and automotive radar systems demand unprecedented signal integrity performance. As data transmission rates push beyond gigahertz frequencies and edge rates approach picosecond domains, maintaining signal fidelity becomes paramount.

The foundation of reliable high-frequency performance lies in controlled impedance PCB design and precise impedance matching strategies that minimize signal distortion, reduce electromagnetic interference, and ensure robust data transmission across complex interconnect systems.

Understanding High Speed PCB Fundamentals

High Speed PCB design encompasses printed circuit boards operating with signal frequencies exceeding 100 MHz or edge rates faster than 1 nanosecond. Unlike conventional PCB applications, high speed designs must address transmission line effects, where trace geometries exhibit characteristic impedance properties that directly influence signal propagation.

The fundamental distinction between standard and high speed PCB designs lies in their treatment of interconnect parasitics. In high frequency environments, PCB traces transition from simple conductors to transmission lines exhibiting distributed capacitance, inductance, and resistance. This transformation necessitates careful consideration of signal integrity, power integrity, and electromagnetic compatibility throughout the design process.

Signal integrity becomes the primary design constraint, requiring controlled impedance management to prevent signal reflections, crosstalk, and timing variations that can compromise system functionality. The criticality of impedance control intensifies as operating frequencies increase, making controlled impedance PCB design an essential engineering discipline for modern electronics.

Controlled Impedance Theory and Transmission Line Effects

What is Controlled Impedance in PCB

Controlled impedance represents the characteristic impedance of transmission lines formed by PCB traces, defined by the fundamental relationship:

Zo = √(L/C)

Where Zo represents characteristic impedance, L denotes inductance per unit length, and C represents capacitance per unit length. This relationship governs how electromagnetic energy propagates along transmission lines within High Speed PCB layout configurations.

When signal transitions times become comparable to propagation delays across trace lengths, interconnects exhibit transmission line behavior. The critical length threshold follows the relationship:

Critical Length = tr / (2 × td)

Where tr represents signal rise time and td denotes propagation delay per unit length. For modern high-speed signals with sub-nanosecond edge rates, traces as short as 10-15 millimeters require impedance control consideration.

Impedance Matching Principles

Impedance matching ensures maximum power transfer and minimizes signal reflections at interconnect interfaces. When source impedance, transmission line impedance, and load impedance align, signal reflections approach zero, preserving signal integrity throughout the transmission path.

Reflection coefficient quantifies impedance mismatch severity:

Γ = (ZL – Zo) / (ZL + Zo)

Where ZL represents load impedance and Zo denotes characteristic impedance. Achieving Γ ≈ 0 requires precise impedance control throughout the signal path, making controlled impedance design fundamental to High Speed PCB performance optimization.

Critical Factors Influencing Impedance in High Speed Applications

Geometric Parameters

Trace width and thickness directly influence characteristic impedance through their impact on capacitance and inductance distribution. For microstrip configurations, increasing trace width decreases impedance by raising capacitance, while increased copper thickness provides similar effects through enhanced current distribution.

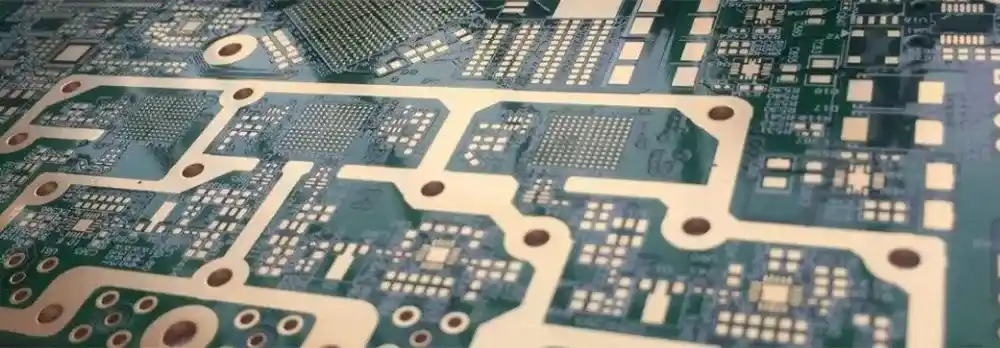

PCB Stackup and Material Selection

PCB stackup design represents the most influential factor in achieving controlled impedance targets. Dielectric thickness between signal layers and reference planes dominates impedance calculations, requiring precise specification during fabrication.

Material selection significantly impacts impedance stability across frequency and temperature ranges. Standard FR4 exhibits dielectric constant variations of ±10% across frequency, while advanced materials like Rogers RT/duroid or Panasonic Megtron provide superior stability with tolerances approaching ±2%.

High Frequency Considerations

At frequencies exceeding 1 GHz, material dispersion effects become prominent, causing frequency-dependent impedance variations. The dielectric constant decreases with increasing frequency, resulting in rising characteristic impedance that must be compensated through design optimization.

Surface roughness effects also become significant at high frequencies, increasing effective resistance and modifying impedance characteristics. Selecting appropriate copper foil treatments and understanding their impact on signal propagation becomes essential for maintaining impedance accuracy.

Impedance Matching Applications in High Speed Interfaces

Modern high-speed digital interfaces demand precise impedance control to achieve specified performance levels. High Speed PCB design for PCIe 4.0/5.0 applications requires 100Ω ±10% differential impedance control to meet signal integrity specifications across multi-gigabit data rates.

DDR4/DDR5 memory interfaces implement 40Ω single-ended and 80Ω differential impedance standards, requiring sophisticated high-speed PCB design techniques to maintain timing margins across parallel data buses. SerDes applications operating beyond 25 Gbps demand impedance tolerances approaching ±5% to minimize jitter accumulation and bit error rates.

RF applications typically standardize on 50Ω characteristic impedance for optimal power transfer and component compatibility. Achieving 50Ω microstrip or stripline configurations requires precise control of trace geometry and stackup parameters, particularly for applications spanning DC to millimeter-wave frequencies.

Advanced Design Methodologies for Controlled Impedance Implementation

Calculation and Simulation Tools

Professional impedance calculation requires sophisticated electromagnetic field solvers that account for three-dimensional field distributions around complex trace geometries. Industry-standard tools including Polar Si9000, Saturn PCB Toolkit, and Ansys SIwave provide accurate impedance predictions incorporating material properties, geometric tolerances, and manufacturing variations.

Microstrip versus Stripline Configurations

Microstrip lines, positioned on external PCB layers with single reference planes, offer design flexibility and heat dissipation advantages but exhibit greater susceptibility to electromagnetic interference. Stripline configurations, embedded between reference planes, provide superior electromagnetic isolation and consistent impedance characteristics across temperature variations.

Selection between microstrip and stripline topologies depends on signal frequency, EMC requirements, and thermal management considerations. High Speed PCB layout often employs hybrid approaches, utilizing striplines for critical signals and microstrips for less sensitive applications.

Manufacturing Tolerance Management

Achieving ±5% impedance tolerance requires comprehensive understanding of fabrication parameter variations. Trace width tolerances typically range from ±1 mil for standard processes to ±0.5 mil for advanced fabrication capabilities. Dielectric thickness variations approach ±10% for standard stackups, necessitating compensation strategies during design optimization.

Copper plating variations, surface roughness effects, and material curing parameters all contribute to final impedance deviation. Successful controlled impedance PCB design requires close collaboration with experienced manufacturers capable of maintaining tight process controls.

Industry Applications and Performance Requirements

Data Center and AI Server Applications

Hyperscale data centers demand High Speed PCB solutions supporting 100+ Gbps interconnect rates across server backplanes and networking equipment. These applications require controlled impedance accuracy within ±3% to maintain signal integrity across meter-scale transmission paths.

5G Communication Infrastructure

5G base station equipment operates across millimeter-wave frequencies, requiring controlled impedance design for both digital signal processing circuits and RF front-end modules. Multi-layer controlled impedance PCB designs must accommodate simultaneous baseband and RF signal routing while maintaining isolation between functional blocks.

Automotive Radar and ADAS Systems

Automotive radar systems operating at 77-79 GHz demand precise impedance control for antenna feed networks and signal processing circuits. Temperature stability becomes critical, requiring material selection and design techniques that maintain impedance accuracy across automotive operating temperature ranges.

Haoyue Electronics: Advanced High Speed PCB Manufacturing Capabilities

Achieving optimal controlled impedance performance requires partnership with manufacturers possessing advanced fabrication capabilities and extensive high-speed design experience. Haoyue Electronics specializes in complex High Speed PCB fabrication, offering comprehensive solutions for demanding applications requiring precise impedance control.

Our manufacturing capabilities include:

- Advanced stackup design optimization with impedance modeling and verification

- Controlled impedance fabrication with ±5% tolerance guarantee across 1-40 layer constructions

- Premium material processing including Rogers, Isola, and Panasonic high-frequency substrates

- HDI technology supporting via-in-pad and blind/buried via configurations for signal routing optimization

- Comprehensive electrical testing including TDR impedance verification and insertion loss characterization

- Complete PCB assembly services with high-speed component placement and advanced soldering techniques

For engineers developing next-generation high-speed systems, Haoyue Electronics provides the manufacturing expertise and quality control necessary to transform controlled impedance designs into reliable production hardware. Contact our engineering team to discuss your controlled impedance PCB requirements and explore how our capabilities can support your project success.

Conclusion

Controlled impedance PCB design represents a fundamental requirement for successful High Speed PCB implementation across modern electronic systems. As data rates continue increasing and signal integrity margins become increasingly stringent, mastering impedance matching techniques, material selection strategies, and manufacturing collaboration becomes essential for engineering teams developing competitive products.

The complexity of achieving controlled impedance in high-frequency applications requires comprehensive understanding of electromagnetic theory, material science, and manufacturing processes. Success depends on integrating these disciplines early in the design process and maintaining close collaboration with experienced fabrication partners capable of delivering precision results.

Future developments in controlled impedance technology will likely focus on advanced materials with improved frequency stability, enhanced manufacturing process controls for tighter tolerances, and integrated design methodologies that optimize impedance characteristics alongside other critical performance parameters.

Frequently Asked Questions

What is controlled impedance in PCB and why is it important for high speed applications?

Controlled impedance in PCB refers to the precise management of characteristic impedance along transmission lines formed by PCB traces. In high speed applications, when signal transition times become comparable to propagation delays, traces behave as transmission lines rather than simple conductors. Controlling impedance ensures proper signal integrity by minimizing reflections, maintaining signal quality, and preventing timing variations that could cause system failures.

Why is impedance matching important in high speed PCB design?

Impedance matching prevents signal reflections that occur when signals encounter impedance discontinuities along their transmission path. In high speed PCB design, unmatched impedances cause signal energy to reflect back toward the source, creating signal distortion, timing jitter, and potential electromagnetic interference. Proper impedance matching ensures maximum power transfer and maintains signal fidelity across the entire interconnect system.

How do you design controlled impedance PCB for optimal performance?

Controlled impedance PCB design requires careful consideration of trace geometry, stackup configuration, and material selection. Key steps include calculating target impedance using electromagnetic simulation tools, optimizing trace width and spacing for desired impedance values, selecting appropriate dielectric materials with stable properties, and working with experienced manufacturers to maintain fabrication tolerances within ±5%. The design process must also account for frequency-dependent effects and manufacturing variations.

What materials are best for controlled impedance PCB stackup design?

Controlled impedance PCB stackup design benefits from low-loss, stable dielectric materials. While standard FR4 suffices for applications below 1 GHz, high-frequency applications require advanced materials like Rogers RT/duroid series, Isola I-Speed, or Panasonic Megtron with consistent dielectric constants and low dissipation factors. Material selection depends on frequency range, temperature stability requirements, and cost considerations.

What are the key impedance matching techniques in High Speed PCB layout?

Impedance matching techniques in High Speed PCB layout include differential pair routing for 100Ω interfaces, proper via design to minimize impedance discontinuities, length matching for timing-critical signals, and careful placement of termination components. Advanced techniques involve using multiple reference planes, implementing coplanar waveguides for critical signals, and optimizing via transitions between layers while maintaining consistent impedance throughout the signal path.