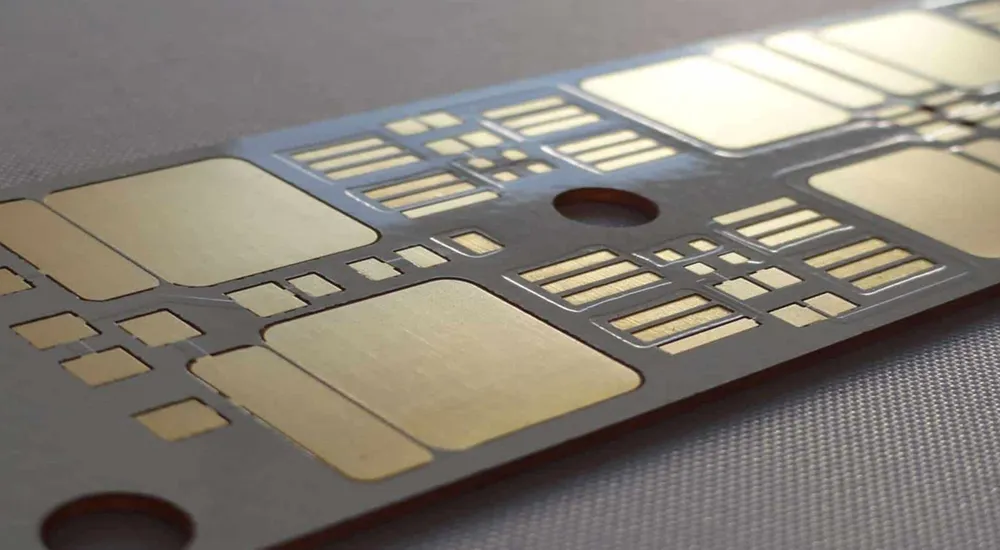

Selecting the optimal ceramic substrate material represents a critical decision point in high-performance printed circuit board design. The choice between alumina, aluminum nitride, and beryllium oxide fundamentally impacts thermal management capabilities, electrical performance, and project economics. This comprehensive analysis examines the key material properties and selection criteria to guide engineers toward the most suitable ceramic PCB substrate for their specific application requirements.

Ceramic PCB Manufacturing Process

The ceramic PCB manufacturing process encompasses several critical stages that demand precise control and specialized equipment. The foundation begins with ceramic substrate preparation, where high-purity ceramic powders undergo careful processing to achieve optimal material properties.

Substrate Formation and Conditioning

Initial substrate preparation involves mixing ceramic powders with organic binders and plasticizers to create a homogeneous slurry. The composition typically contains 90-96% ceramic powder with carefully controlled particle size distribution. Tape casting technology produces uniform thickness sheets ranging from 0.25mm to 2.0mm, with thickness tolerances maintained within ±10 micrometers.

The green ceramic sheets undergo controlled drying at temperatures between 80-120°C to remove solvents while preventing cracking or warping. Critical process parameters include humidity control below 50% and controlled cooling rates to minimize internal stress formation. Surface preparation involves precision grinding to achieve Ra values below 0.4 micrometers, essential for subsequent metallization adhesion.

High-Temperature Sintering Operations

Sintering represents the most critical phase in ceramic substrate manufacturing, transforming the green ceramic into a dense, mechanically robust substrate. The process occurs in controlled atmosphere furnaces at temperatures ranging from 1350-1650°C, depending on the ceramic composition.

Temperature profiles require precise control with heating rates typically limited to 2-5°C per minute during critical transition zones. Atmosphere control prevents oxidation of metallic components while ensuring complete organic burnout. Sintering schedules extend 12-24 hours for thick substrates, with cooling rates controlled to prevent thermal shock and maintain dimensional accuracy within ±0.1%.

Ceramic PCB Material Selection Criteria

Material selection for ceramic PCB applications requires systematic evaluation of thermal, electrical, mechanical, and economic factors. The selection process must balance performance requirements against cost constraints while considering manufacturing feasibility and safety considerations.

Thermal Performance Analysis

Thermal conductivity represents the most critical parameter for ceramic PCB material selection. Alumina substrates provide thermal conductivity values between 24-28 W/mK, making them suitable for moderate heat dissipation applications. This thermal performance significantly exceeds FR4 materials (0.3-0.4 W/mK) while maintaining cost-effectiveness for volume production.

Aluminum nitride delivers exceptional thermal conductivity ranging from 140-180 W/mK, with some high-purity variants reaching 200+ W/mK. This performance level approaches metal thermal conductivity while maintaining electrical insulation properties. The coefficient of thermal expansion (CTE) for aluminum nitride closely matches silicon semiconductor materials at 4.0-6.0 × 10⁻⁶/K, ensuring reliable thermal cycling performance in semiconductor packaging applications.

Beryllium oxide achieves the highest thermal conductivity among ceramic materials, reaching 250-330 W/mK. This exceptional thermal performance enables heat dissipation capabilities that exceed many metal substrates while providing electrical isolation. The CTE of beryllium oxide (7.4-8.9 × 10⁻⁶/K) offers good matching with semiconductor devices.

Electrical Characteristics and Dielectric Properties

The dielectric properties of ceramic substrates directly impact high-frequency performance and signal integrity. Alumina substrates exhibit dielectric constants between 9.6-10.2 with excellent electrical insulation properties. The electrical strength of 15-20 kV/mm provides reliable performance for high-voltage applications.

Aluminum nitride demonstrates superior electrical characteristics with dielectric constants of 8.7-9.3 and electrical strength comparable to alumina. The lower dielectric constant benefits high-frequency applications by reducing signal propagation delays and minimizing dielectric losses.

Beryllium oxide offers the lowest dielectric constant among ceramic materials (6.7-7.2) combined with exceptional electrical strength (40-45 kV/mm). These properties make beryllium oxide ideal for high-frequency RF and microwave applications where signal integrity is paramount.

Cost-Performance Trade-offs in Ceramic Substrate Selection

The economic considerations for ceramic PCB material selection involve initial material costs, manufacturing complexity, and long-term reliability factors. Alumina substrates represent the most cost-effective option, with material costs significantly lower than aluminum nitride or beryllium oxide alternatives.

Manufacturing Cost Implications

Alumina ceramic substrates offer established manufacturing processes with readily available equipment and expertise. The abundance of raw materials and mature processing technology results in competitive pricing for high-volume applications. Standard thick-film and thin-film processing techniques apply directly to alumina substrates without specialized equipment requirements.

Aluminum nitride substrates command premium pricing due to specialized processing requirements and controlled atmosphere sintering. The material costs typically range 3-5 times higher than equivalent alumina substrates. However, the superior thermal performance often justifies the increased expense in high-power density applications where thermal management is critical.

Beryllium oxide represents the highest-cost option among ceramic substrates due to material toxicity concerns and specialized handling requirements. Safety protocols for beryllium oxide processing increase manufacturing costs significantly. Additionally, regulatory restrictions limit the availability of beryllium oxide processing facilities, further impacting cost and lead times.

Long-term Value Analysis

The total cost of ownership for ceramic PCB materials extends beyond initial substrate costs to include assembly yields, reliability performance, and field failure rates. Aluminum nitride substrates often demonstrate superior long-term value in high-power applications due to improved thermal management reducing component stress and extending operational lifetimes.

The mechanical properties of ceramic substrates impact assembly yields and handling costs. Alumina substrates provide excellent mechanical strength and resistance to thermal shock, minimizing manufacturing losses. Aluminum nitride exhibits lower mechanical strength but adequate durability for most applications when proper handling procedures are implemented.

Application-Specific Material Recommendations

Different application categories favor specific ceramic substrate materials based on performance requirements and operating conditions. High-power LED applications benefit from aluminum nitride substrates where thermal management directly impacts light output and operational lifetime. The superior thermal conductivity of aluminum nitride enables higher power densities while maintaining acceptable junction temperatures.

Power Electronics and Motor Drives

Power electronics applications requiring high current handling and thermal cycling performance favor aluminum nitride or beryllium oxide substrates. The low CTE and high thermal conductivity minimize thermal stress on power semiconductor devices while enabling compact packaging designs. Alumina substrates prove suitable for lower power density applications where cost considerations outweigh thermal performance requirements.

RF and Microwave Applications

High-frequency applications benefit from the low dielectric constant and excellent electrical properties of beryllium oxide substrates. The superior electrical characteristics enable improved signal integrity and reduced losses in RF circuits. Aluminum nitride provides an alternative for RF applications where the cost and safety concerns of beryllium oxide are prohibitive.

LED and Optical Applications

LED applications demanding maximum light output and extended operational life require substrates with exceptional thermal conductivity. Aluminum nitride substrates enable higher power densities while maintaining acceptable junction temperatures. The white appearance of alumina substrates provides optical advantages in LED applications where light reflection is beneficial.

Haoyue Electronics: Advanced Ceramic PCB Manufacturing Capabilities

Given the complex requirements and specialized processing needed for ceramic PCB fabrication, partnering with an experienced manufacturer becomes essential for project success. Haoyue Electronics brings comprehensive ceramic PCB manufacturing and assembly expertise to support demanding applications across multiple industries.

Our ceramic PCB capabilities encompass the complete range of substrate materials and processing technologies required for advanced electronic systems. Key manufacturing strengths include:

- Alumina substrate processing with 96% and 99% purity options for an optimal balance of cost and performance.

- Aluminum nitride PCB fabrication using controlled atmosphere sintering for maximum thermal performance.

- Direct bonded copper (DBC) and direct plated copper (DPC) metallization technologies for robust conductor layers.

- High-temperature assembly processes tailored to the unique characteristics of ceramic substrates.

- Precision drilling and via formation for complex multilayer ceramic structures.

- Comprehensive testing protocols to validate both thermal and electrical performance.

Our engineering team offers material selection guidance based on your application’s requirements, helping you achieve the best balance of performance and cost. From prototypes to high-volume production, Haoyue Electronics delivers the expertise needed for successful ceramic PCB implementation.