Ceramic PCB manufacturing cost represents a significant investment for electronics manufacturers seeking superior thermal performance and reliability. Understanding the cost drivers in ceramic PCB production enables informed budget planning and strategic decision-making for high-performance applications. This comprehensive cost analysis examines the primary factors affecting ceramic PCB manufacturing expenses and provides actionable insights for cost optimization in ceramic PCB solutions.

Key Cost Drivers in Ceramic PCB Manufacturing

Ceramic PCB material cost factors form the foundation of manufacturing expenses. The selection between alumina, aluminum nitride, and beryllium oxide substrates creates substantial cost variations based on thermal performance requirements. Alumina substrates offer cost-effective ceramic PCB solutions for standard applications, while aluminum nitride commands premium pricing for superior thermal conductivity applications.

Material Selection Impact on Production Budget

Manufacturing cost control in ceramic PCBs begins with strategic substrate selection. Alumina (Al₂O₃) provides baseline thermal performance at competitive pricing, making it suitable for general electronics applications. Aluminum nitride (AlN) delivers exceptional thermal conductivity at higher material costs, justifying its use in power electronics and LED applications requiring intensive heat dissipation.

Beryllium oxide represents the premium tier with outstanding thermal properties but carries significant cost penalties due to material scarcity and specialized handling requirements. Cost efficiency in high-performance PCBs demands careful evaluation of actual thermal requirements versus material expenses.

Substrate Thickness and Dimensional Considerations

Board dimensions directly correlate with ceramic PCB fabrication cost breakdown. Thicker substrates provide enhanced mechanical stability and thermal spreading but increase both material consumption and processing time. Standard thickness ranges from 0.25mm to 2.0mm, with custom specifications requiring specialized tooling that affects overall production costs.

Manufacturing Process Complexity and Cost Implications

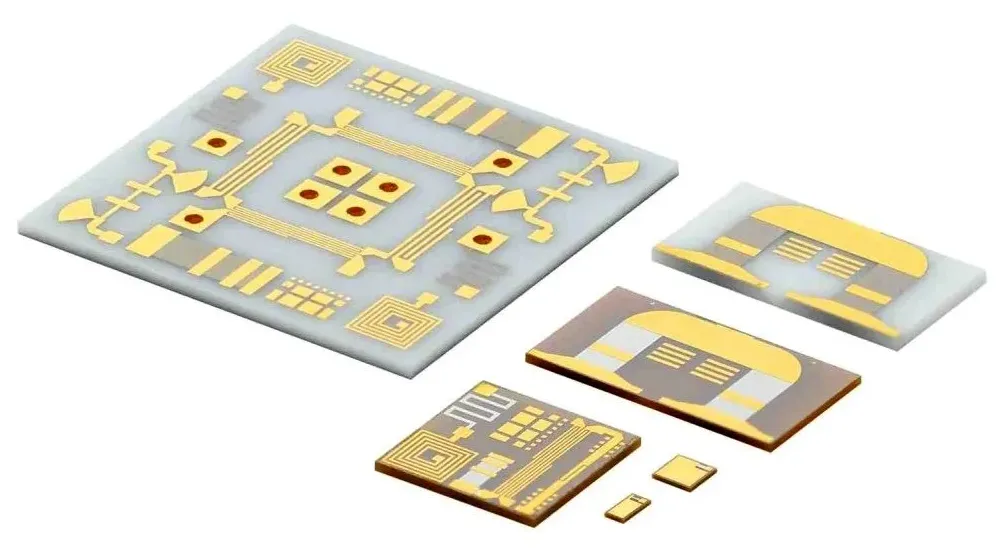

PCB manufacturing process complexity significantly influences ceramic PCB production budget tips. Direct Bonded Copper (DBC) processes offer superior thermal performance through high-temperature copper bonding but require specialized equipment and extended processing cycles. Direct Plated Copper (DPC) enables finer line geometries through sputtering and electroplating techniques, though at higher processing costs.

Advanced Manufacturing Technologies

Low-Temperature Co-fired Ceramic (LTCC) and High-Temperature Co-fired Ceramic (HTCC) processes enable multilayer ceramic construction but involve complex fabrication sequences. These technologies require precise layer registration, controlled firing profiles, and specialized materials, contributing to elevated production costs for complex circuit designs.

Circuit layout optimization presents opportunities for reducing expenses in PCB manufacturing. Simplified routing patterns, standardized via sizes, and reduced layer counts minimize processing steps and improve manufacturing yield rates.

Volume Production and Economic Scale Benefits

Production volume represents a critical factor affecting ceramic PCB price structures. Small-batch production carries higher per-unit costs due to setup expenses, tooling amortization, and calibration requirements. Volume manufacturing enables cost distribution across larger quantities, substantially reducing unit pricing for ceramic PCB projects.

Prototype to Production Scaling

Budget planning for ceramic PCB manufacturing should consider the transition from prototype quantities to volume production. Initial development phases require flexibility for design iterations, while production phases benefit from standardized processes and bulk material procurement. Strategic volume planning optimizes manufacturing cost trajectories across project lifecycles.

Metallization Systems and Conductor Selection

Metallization choices create substantial cost variations in ceramic PCB manufacturing. Silver thick-film conductors offer excellent electrical properties at moderate costs but may require environmental protection in humid applications. Copper metallization provides superior thermal and electrical performance, particularly in DBC applications, though copper thickness requirements directly impact material costs.

Premium Conductor Materials

Gold and platinum metallization systems deliver exceptional reliability for aerospace and medical applications but command premium pricing. These materials justify their costs in applications requiring long-term stability and corrosion resistance. Cost-effective ceramic PCB solutions balance conductor performance requirements with budget constraints through selective metallization strategies.

Quality Requirements and Testing Protocols

Ceramic substrate cost considerations extend beyond basic manufacturing to encompass quality assurance and testing protocols. Tight tolerance requirements necessitate advanced processing equipment and multiple inspection stages, reducing manufacturing yield and increasing production costs.

Inspection and Reliability Testing

Industries requiring high reliability standards implement comprehensive testing protocols including electrical continuity testing, thermal cycling, and mechanical stress evaluation. These quality measures ensure ceramic PCB performance but contribute to overall manufacturing expenses through extended processing time and potential rework requirements.

Why Choose Haoyue Electronics for Your Ceramic PCB Manufacturing Needs

Haoyue Electronics combines extensive ceramic PCB manufacturing expertise with cost optimization strategies to deliver exceptional value for high-performance electronics projects. Our comprehensive capabilities encompass the complete ceramic PCB production and assembly process:

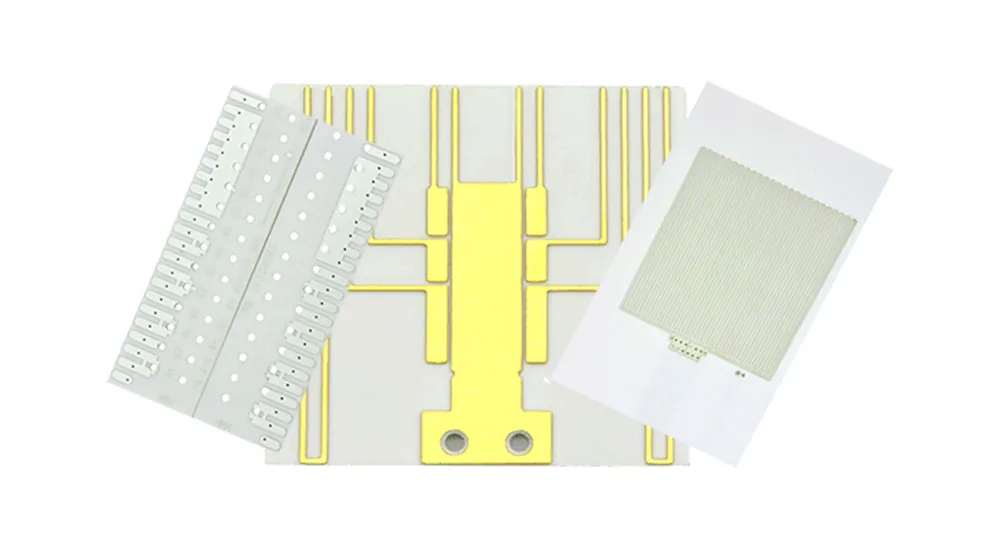

- Advanced ceramic substrate processing capabilities including DBC, DPC, and thick-film technologies

- Expertise in alumina, aluminum nitride, and specialty ceramic materials for diverse thermal requirements

- Precision manufacturing with tight tolerance control for demanding applications

- Comprehensive assembly services including component mounting and system integration

- Volume production capabilities with competitive pricing for cost-effective ceramic PCB solutions

- Quality assurance protocols meeting aerospace, automotive, and medical industry standards

Our engineering team collaborates with clients to optimize ceramic PCB designs for both performance and cost efficiency, ensuring your projects achieve technical objectives within budget parameters.