Introduction

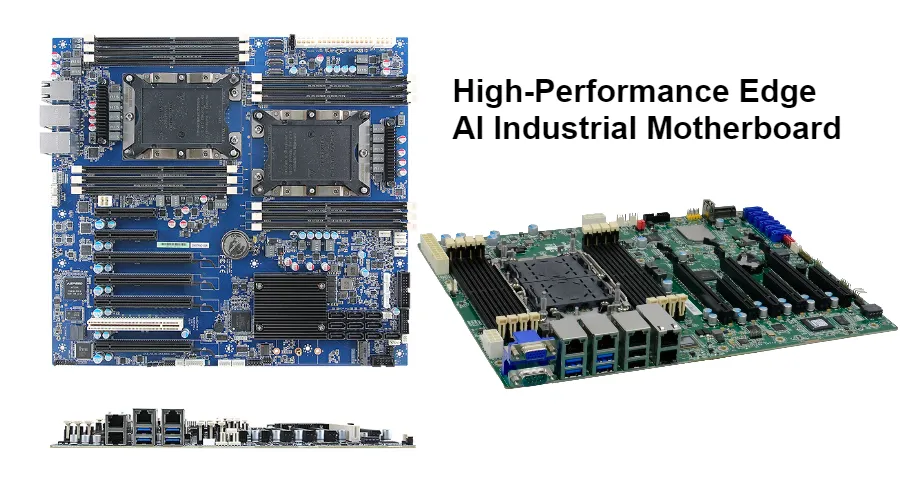

AI Motherboard PCB represents the pinnacle of printed circuit board engineering, designed specifically to meet the demanding requirements of artificial intelligence computing systems. These specialized server motherboard PCBs must support unprecedented data throughput, manage substantial power delivery, and maintain signal integrity across complex high-speed interconnects. Unlike conventional PCBs, AI computing hardware PCB designs require advanced materials, precise manufacturing tolerances, and sophisticated thermal management solutions to enable next-generation AI processors and accelerators.

The evolution of AI computing has fundamentally transformed motherboard PCB requirements. Modern AI systems demand multi-layer PCB constructions with 20-40 layers, support for PCIe 5.0/6.0 interfaces, DDR5 and HBM3 memory architectures, and power delivery systems capable of handling 300-800W per processor socket. This technical complexity necessitates specialized design methodologies, advanced materials, and precision manufacturing capabilities that distinguish AI motherboard PCBs from standard computing platforms.

AI Motherboard PCB Architecture and Technical Requirements

Layer Stack-up and Signal Routing

AI motherboard PCB designs typically employ 20-40 layer constructions to accommodate the dense routing requirements of modern AI processors. The layer stack-up must carefully balance signal layers, power planes, and ground planes to maintain controlled impedance environments. Critical design parameters include:

Signal Layer Allocation:

- High-speed differential pairs (PCIe 5.0/6.0): 4-8 dedicated layers

- DDR5/HBM3 memory interfaces: 6-12 layers with length matching

- Power delivery networks: 4-6 dedicated copper planes

- Ground reference planes: Distributed throughout stack-up

Impedance Control Requirements:

- Single-ended signals: 50Ω ±10%

- Differential pairs: 100Ω ±10%

- Memory interfaces: 40Ω/80Ω differential

- Power delivery: <1mΩ DC resistance per plane

Power Delivery Network Design

AI processors require sophisticated power delivery networks capable of supplying clean, stable power across multiple voltage domains. Modern AI chips demand:

- Core voltages: 0.7-1.2V at 200-400A

- Memory voltages: 1.1-1.35V at 50-100A

- I/O voltages: 1.8-3.3V at variable currents

- Auxiliary supplies: Multiple rails for PLLs and analog circuits

The power delivery network must maintain voltage regulation within ±3% under dynamic loading conditions while minimizing power delivery network impedance below 1mΩ across the frequency spectrum from DC to 1GHz.

Advanced Materials and Manufacturing Processes

Substrate Materials for High-Performance Applications

AI motherboard PCB manufacturing demands premium substrate materials that can maintain electrical performance under extreme operating conditions. The selection criteria extend beyond standard FR-4 requirements to include:

Low-Loss Dielectric Materials:

- Rogers RO4350B: Dk=3.48, Df=0.0037 at 10GHz

- Isola IS620: Dk=3.15, Df=0.0090 at 10GHz

- Panasonic Megtron 6: Dk=3.17, Df=0.0021 at 28GHz

- TUC TU-768: Ultra-low loss for 56Gbps+ applications

Thermal Management Substrates:

- High thermal conductivity cores (2-8 W/mK)

- Embedded copper coin technology for localized heat spreading

- Thermally conductive via-fill materials

- Metal core integration for critical thermal zones

Precision Manufacturing Capabilities

The manufacturing of AI motherboard PCBs requires advanced production capabilities that exceed standard PCB manufacturing tolerances:

Via Technology:

- Micro-vias: 50-75μm finished diameter

- Buried and blind via constructions

- Via-in-pad with planarized surfaces

- Laser drilling accuracy: ±12μm positional tolerance

Copper Plating and Finishing:

- Heavy copper capabilities: 3-6oz base copper

- Precision plating thickness control: ±10%

- ENIG, ENEPIG, and OSP surface finishes

- Selective plating for impedance optimization

AI Computing Motherboard

Signal Integrity and High-Speed Design Considerations

Differential Pair Routing and Length Matching

High-speed signal integrity in AI motherboard PCBs requires meticulous attention to transmission line characteristics and timing relationships. The design must accommodate multiple high-speed protocols operating simultaneously:

PCIe 5.0/6.0 Design Requirements:

- Data rates: 32-64 Gbps per lane

- Differential impedance: 85Ω ±15%

- Intra-pair skew: <5ps

- Inter-pair skew: <20ps within x16 groups

Memory Interface Design:

- DDR5-4800/5600: Setup/hold timing margins <50ps

- Trace length matching: ±25μm for clock groups

- Via count minimization: <2 vias per critical signal

- Return path continuity across all layer transitions

Advanced Simulation and Verification: The complexity of AI motherboard PCB designs necessitates comprehensive pre-layout simulation and post-layout verification using advanced electromagnetic field solvers. Critical simulation requirements include:

- 3D electromagnetic field analysis for accurate impedance extraction

- Time-domain reflectometry simulation for signal quality verification

- Power delivery network impedance analysis across 1MHz-1GHz frequency range

- Simultaneous switching noise analysis for multi-gigabit interfaces

- Thermal-electrical co-simulation for power-sensitive signal paths

EMI/EMC Design Strategies

AI computing systems generate significant electromagnetic interference due to high-frequency switching and substantial current demands. Effective EMI mitigation strategies include:

- Strategic ground plane segmentation with controlled return paths

- Differential signaling implementation for noise immunity

- Guard traces and shielding structures for sensitive analog circuits

- Proper component placement to minimize coupling between circuits

- Via stitching patterns to maintain ground plane continuity

Application Scenarios and Market Segments

Data Center AI Infrastructure

Modern data center AI motherboard PCBs must support rack-scale computing architectures with multiple AI accelerator cards, high-bandwidth networking interfaces, and advanced cooling systems. These applications require:

- Multi-socket CPU configurations with NUMA optimization

- PCIe switch integration for accelerator card connectivity

- 25/100/400GbE networking interface support

- Advanced thermal interface materials and heat spreading

Edge Computing Platforms

Edge AI applications demand compact, power-efficient motherboard designs that maintain performance in challenging environmental conditions. Key requirements include:

- Reduced form factors with optimized component placement

- Extended temperature range operation (-40°C to +85°C)

- Enhanced mechanical durability for mobile applications

- Power efficiency optimization for battery-powered systems

Research and Development Platforms

Scientific computing and AI research platforms require highly configurable motherboard architectures that can adapt to evolving computational requirements:

- Modular expansion capabilities for future upgrades

- Advanced debugging and monitoring interfaces

- Support for experimental processor architectures

- High-speed storage interface integration (NVMe, CXL)

Quality and Reliability Assurance

Materials Inspection and Process Control

AI motherboard PCB manufacturing requires stringent quality control measures throughout the production process:

Incoming Material Verification:

- Dielectric constant and loss tangent validation

- Thermal conductivity and coefficient of thermal expansion testing

- Copper foil adhesion and surface roughness measurement

- Dimensional stability verification across temperature cycling

Process Monitoring and Control:

- Real-time impedance monitoring during production

- Statistical process control for critical dimensions

- Automated optical inspection for layer-to-layer registration

- X-ray inspection for via fill quality and internal defects

Environmental and Reliability Testing

AI computing environments subject motherboard PCBs to demanding operational conditions that require comprehensive reliability validation:

- Thermal Cycling: -55°C to +125°C, 1000+ cycles

- Mechanical Stress Testing: Vibration and shock per IPC-2221

- Accelerated Life Testing: 85°C/85% RH for 1000+ hours

- Electrical Stress Testing: High-voltage isolation and insulation resistance

- Signal Integrity Verification: TDR/TDT measurement across frequency spectrum

Conclusion

AI Motherboard PCB design and manufacturing represents one of the most challenging applications in the printed circuit board industry. The combination of high-speed signal requirements, complex power delivery networks, and demanding thermal management creates unique engineering challenges that require specialized expertise and advanced manufacturing capabilities.

Success in AI motherboard PCB projects depends on careful selection of materials, precise manufacturing execution, and comprehensive testing and validation. The rapid evolution of AI computing architectures continues to push the boundaries of what is possible in PCB design and manufacturing.

For organizations developing AI computing systems, partnering with an experienced manufacturer like Haoyue Electronics ensures access to the specialized capabilities and expertise required for successful AI motherboard PCB implementation. Our commitment to technical excellence, quality assurance, and customer collaboration makes us the ideal partner for your most demanding AI computing hardware projects.

Ready to advance your AI computing hardware design? Contact Haoyue Electronics today to discuss your AI motherboard PCB requirements and discover how our advanced manufacturing capabilities can accelerate your project timeline while ensuring the highest levels of performance and reliability.

Haoyue Electronics: Advanced AI Motherboard PCB Manufacturing Excellence

The sophisticated requirements of AI motherboard PCB manufacturing demand a manufacturing partner with proven expertise in high-complexity, high-reliability printed circuit board production. Haoyue Electronics brings decades of specialized experience in advanced PCB manufacturing and assembly services specifically tailored for AI computing applications.

Our comprehensive AI motherboard PCB manufacturing capabilities include:

- Layer Count Expertise: 4-50 layer constructions with advanced HDI technology

- Material Specialization: Certified processing of Rogers, Isola, and premium low-loss substrates

- Impedance Control: ±5% tolerance across all signal types with comprehensive testing

- Advanced Via Technology: Micro-vias, blind/buried vias, and via-in-pad constructions

- Heavy Copper Capabilities: 1-12oz copper weights with precision thickness control

- Assembly Services: Complete SMT and through-hole assembly with BGA and fine-pitch components

- Testing and Validation: In-circuit testing, functional verification, and signal integrity validation

- Quality Certifications: ISO 9001:2015, IPC Class 3, and IATF 16949 compliance

Our engineering team collaborates closely with customers throughout the design-for-manufacturability process, ensuring optimal performance, reliability, and cost-effectiveness for AI motherboard PCB projects. From prototype development through high-volume production, Haoyue Electronics delivers the precision and quality that AI computing applications demand.

Frequently Asked Questions

What layer count is required for AI motherboard PCBs?

AI motherboard PCBs typically require 20-40 layers to accommodate the complex routing requirements of modern AI processors, memory interfaces, and power delivery networks. The exact layer count depends on the specific processor architecture, memory configuration, and expansion interface requirements.

How do you ensure signal integrity in high-speed AI motherboard designs?

Signal integrity is maintained through controlled impedance design, precise length matching, proper via placement, and comprehensive electromagnetic simulation. Critical factors include differential pair routing, return path continuity, and minimization of discontinuities in transmission line structures.

What PCB materials are recommended for AI motherboard applications?

Premium low-loss materials such as Rogers RO4350B, Isola IS620, or Panasonic Megtron 6 are recommended for AI motherboard PCBs. These materials provide superior electrical performance, thermal stability, and reliability compared to standard FR-4 substrates.

What is the typical lead time for AI motherboard PCB prototypes?

Custom AI motherboard PCB prototypes typically require 2-4 weeks for manufacturing, depending on layer count, materials, and complexity. Rush services may be available for urgent requirements with expedited processing.

How do you address thermal management in AI motherboard PCB design?

Thermal management strategies include heavy copper planes, thermal vias, embedded copper coins, and thermally conductive substrate materials. The thermal design must be integrated with the electrical design to maintain signal integrity while providing effective heat dissipation.